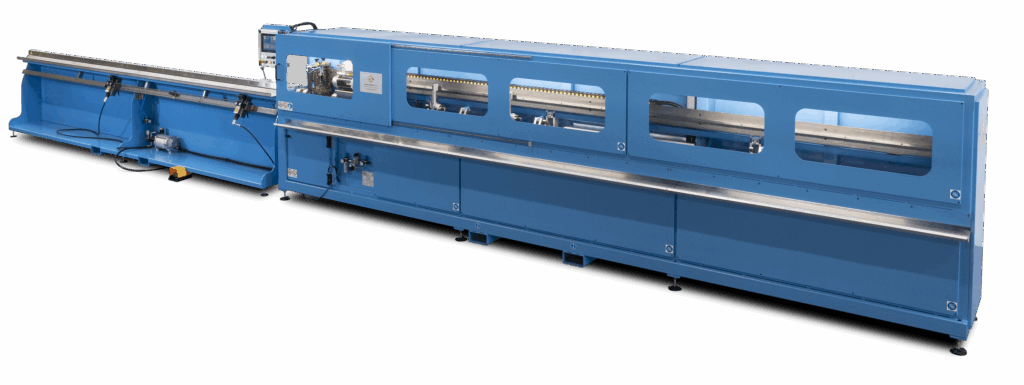

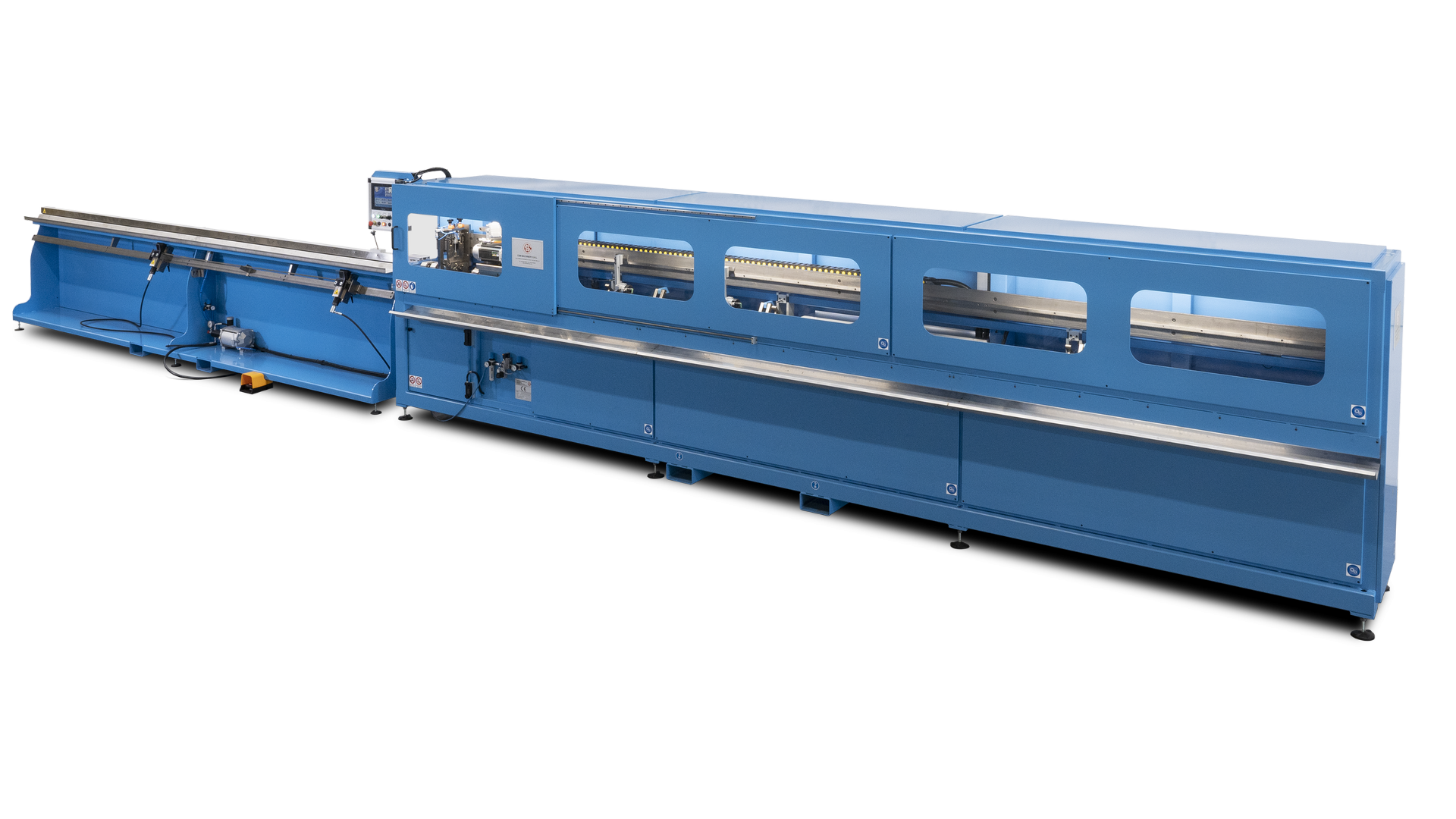

The CSM MACHINERY finning machine precisely and quickly wraps a strip around a tube or a tubular heating element forming a fin around it. This is achieved through its latest-generation numerical control (NC) system.

To meet diverse production needs, the machine can be equipped with additional tooling kits to apply fins to heating elements of various diameters and with different strip widths. Furthermore, operators can easily set and recall fin pitch and main working parameters directly from the operator panel, eliminating the need for machine re-tooling.

The concrete advantages that make the difference

Double productivity compared to traditional systems.

Set directly from the operator panel.

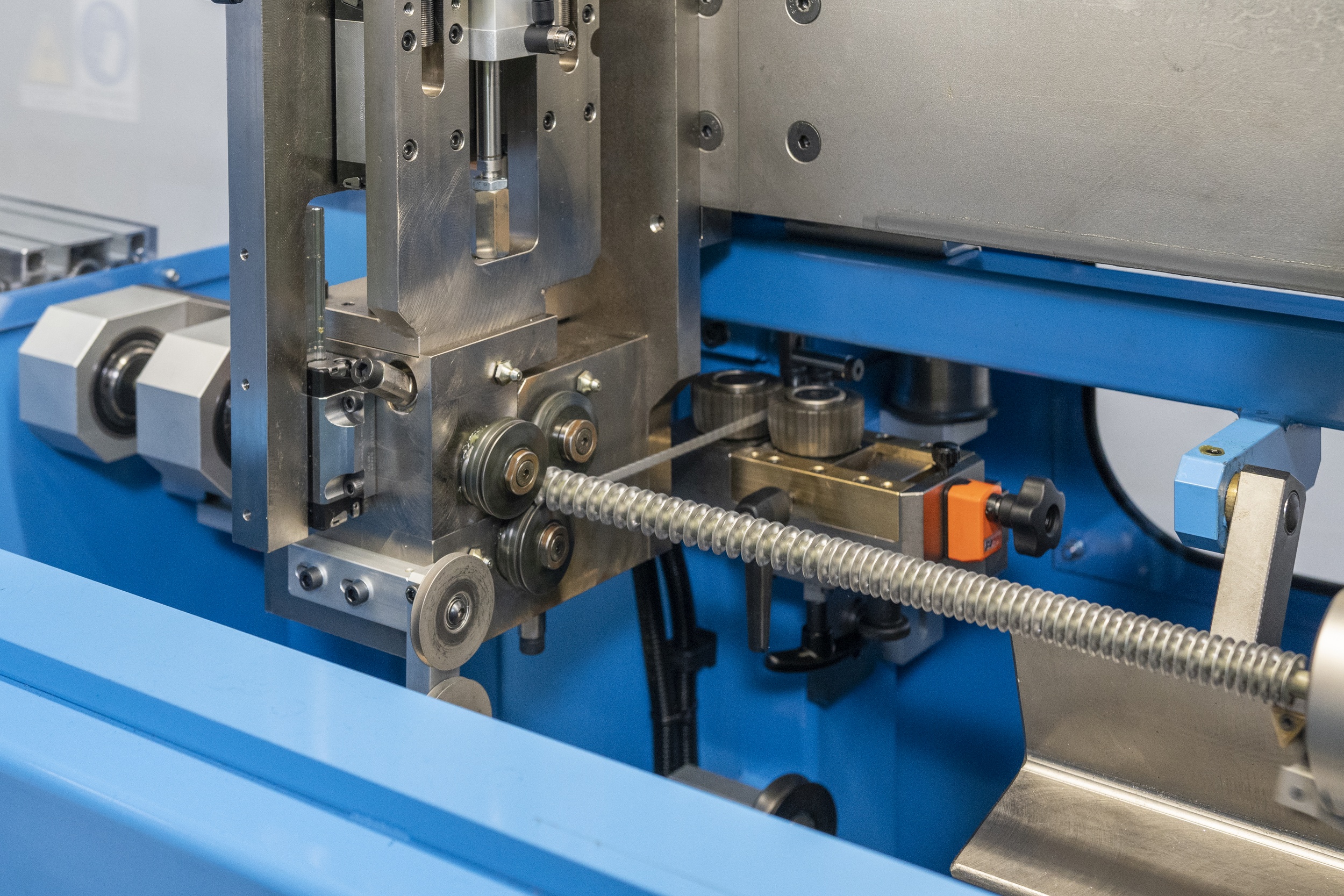

Position indicators allow recalling of head and roll positions, streamlining and simplifying machine setup.

Discover all the machine details

SUPPORT FOR THE ELEMENTS before finning

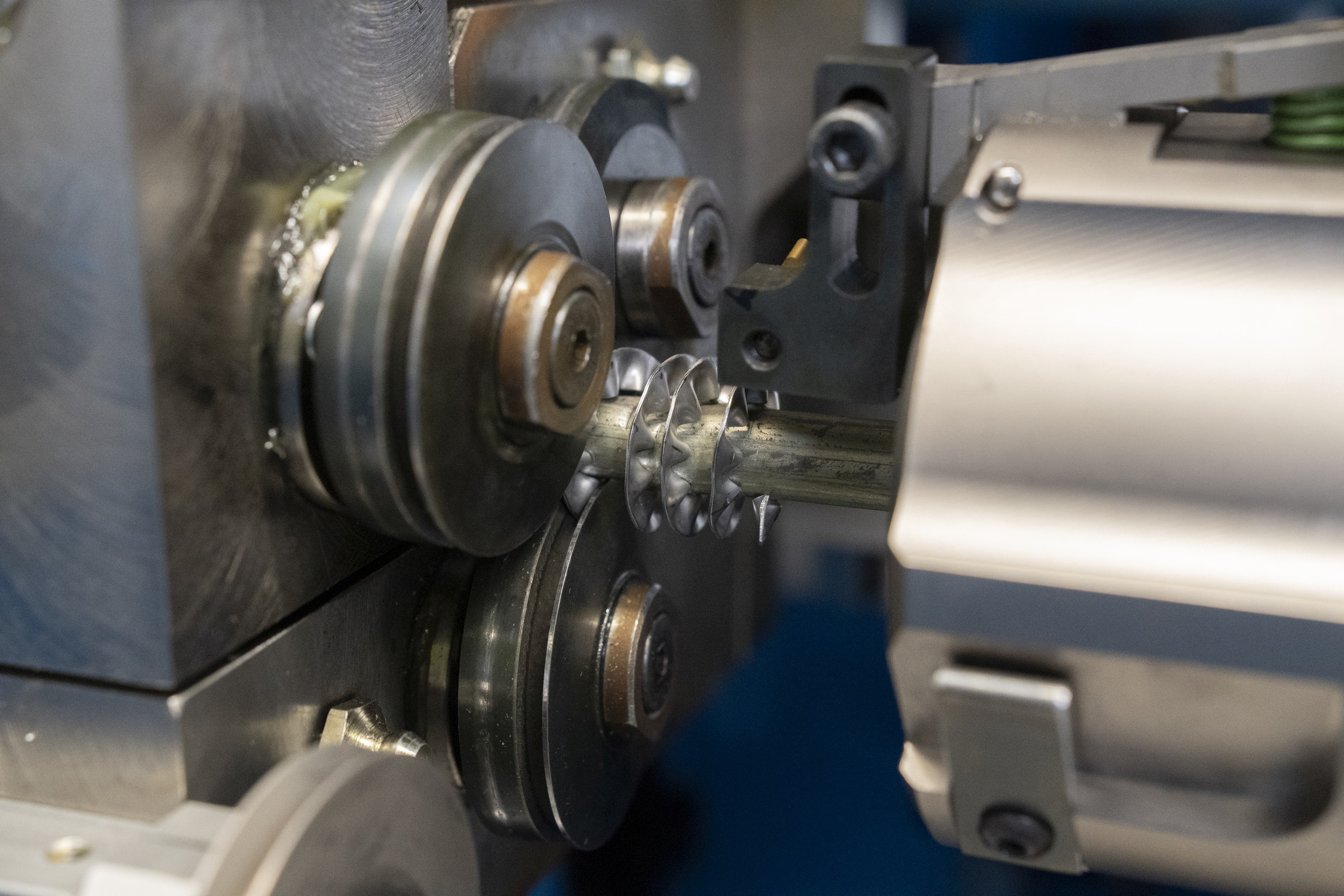

FINNING HEAD

The finning head will stop at the loading position indicated by the operator interface, ensuring the correct distance between the end of the tube and the first fin.

HORIZONTAL DEREELER

CRINKLING DEVICE

FINNING CARRIAGE

The element is pushed forward until it stops on the rotating spindle’s stop of the finning carriage.

UNLOADING SECTION

of heating elements produced

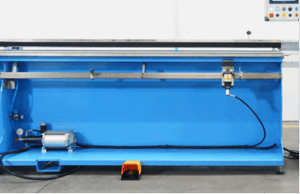

Pneumatic device to press the ends of the tube to improve grip between the tube and fin for tube thickness up to 0.5 mm.

CSM device to facilitate the unwinding of the strip.

Coil holder with braking system.

Set of spare parts for tubes with different diameters, finning wheel set, and toothed wheel set for forming the fold on the fin.

Pneumatic device to press the ends of the tube to improve grip between the tube and fin for tube thickness up to 0.5 mm.

CSM device to facilitate the unwinding of the strip.

Coil holder with braking system.

Set of spare parts for tubes with different diameters, finning wheel set, and toothed wheel set for forming the fold on the fin.

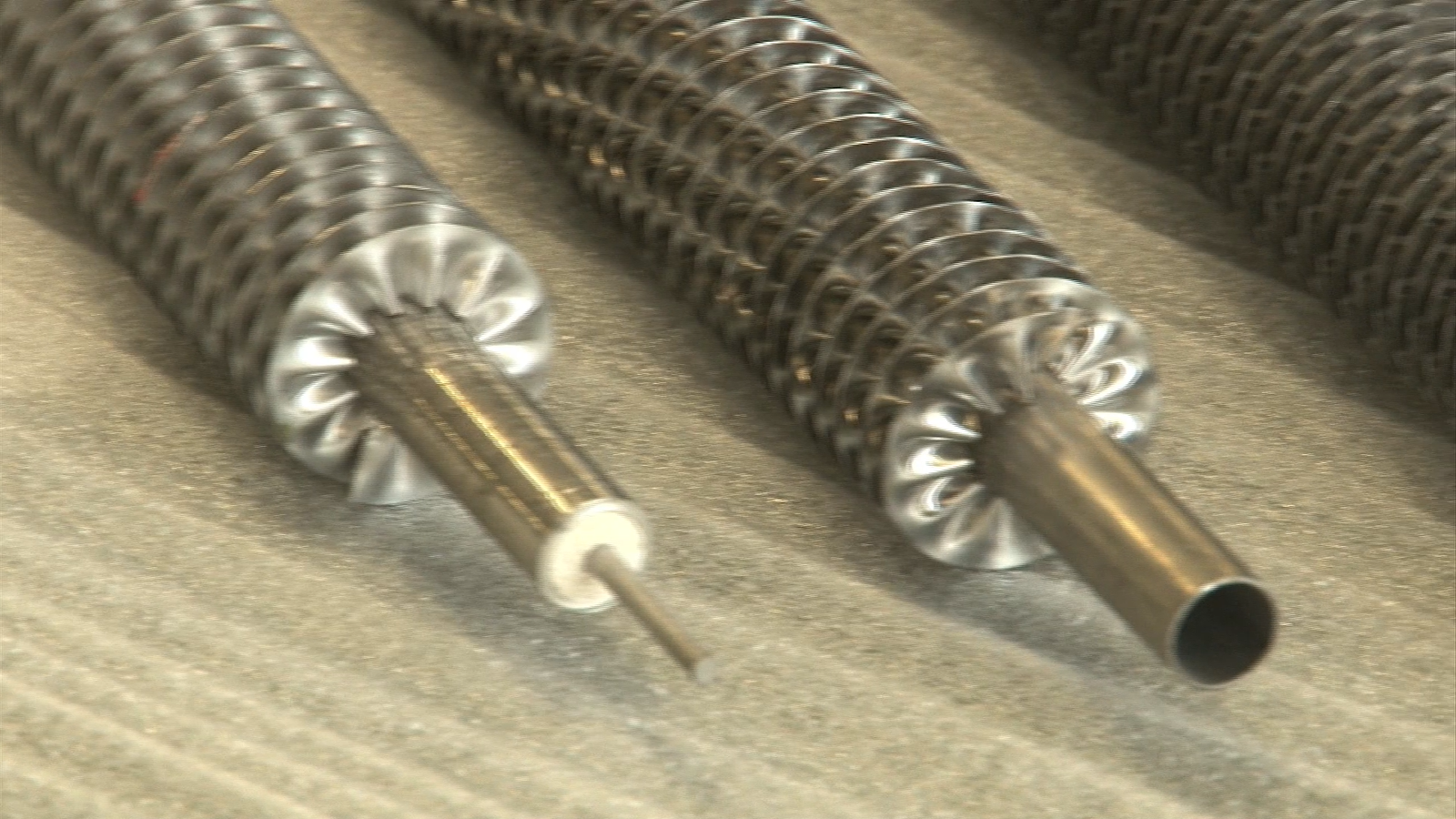

Tube material | steel, stainless steel |

Tube diameter | 6-16 mm |

Minimum tube length | 300 mm |

Min. tube thickness – for finned tube | 1 mm |

Min. tube thickness – for finned heating element | 0,40 mm |

Strip material | acciaio, acciaio inox, rame |

Strip width | 6-12 mm |

Strip thickness – steel, stainless steel, copper | 0,3-0,5 mm |

Fin pitch (adjustable) | 2-15 mm |

Winding speed (adjustable) | 0/1000 giri/min |

Supply voltage | V/Hz da definire |

Pneumatic supply | 6 Bar |

Installed power | 8 KVA |

Dimensions | 7000x1800x1600 mm |

Discover the other products in our range