CSM Machinery has a lot of experience in coil preparation and is able to propose a number of solutions in pin-coil welding. According to the required production rates, these devices feature coil-pin-plug assembly units with manual, semi-automatic or full-automatic function.

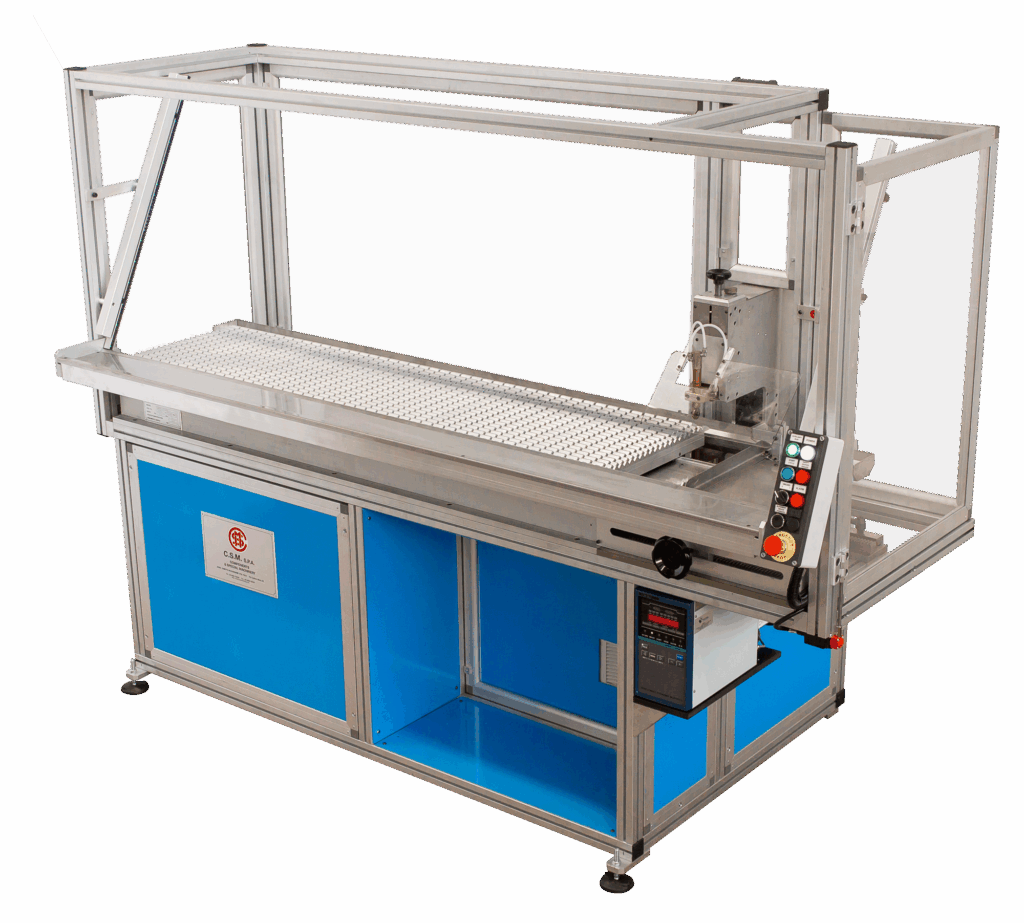

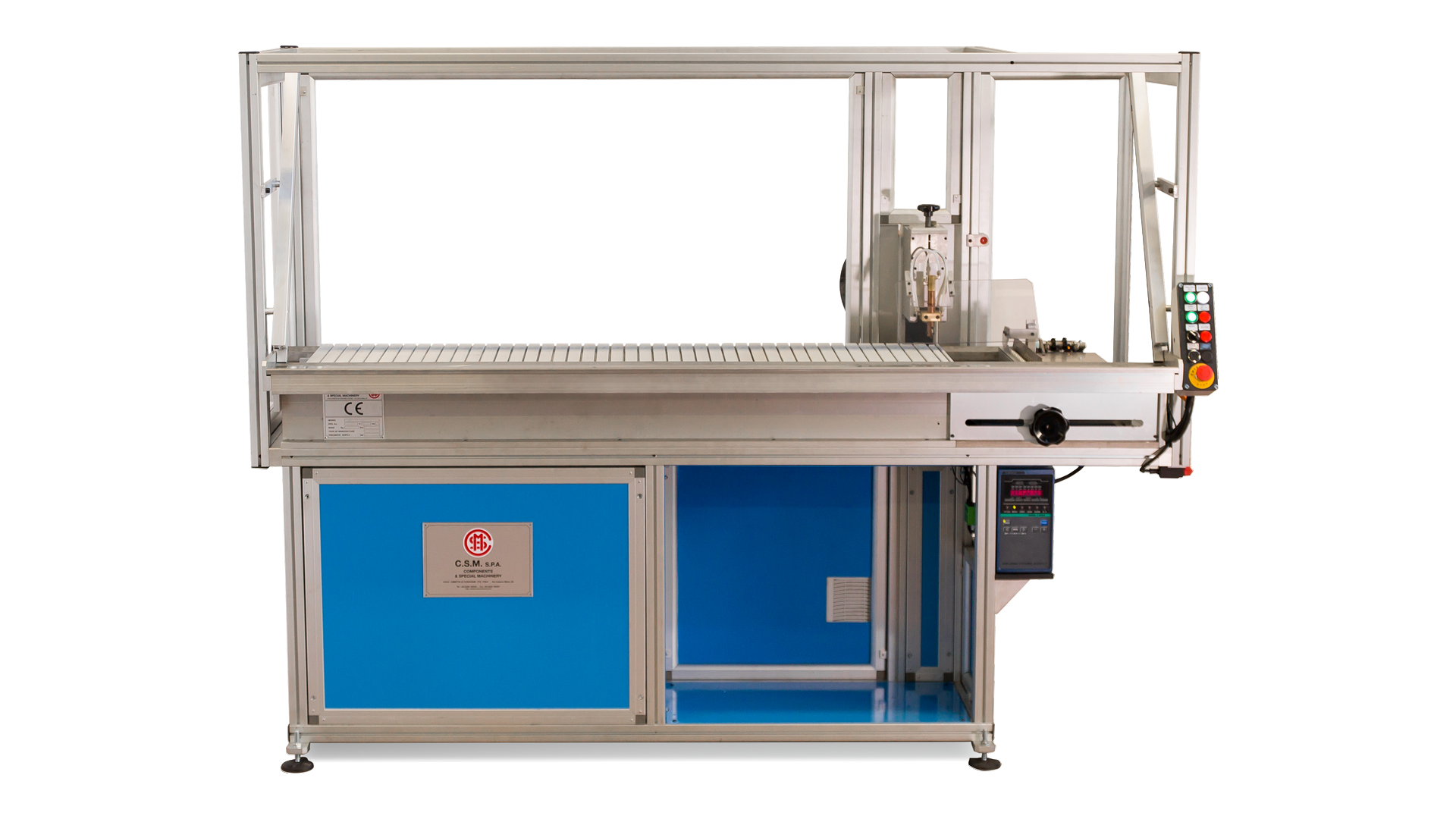

The semi-automatic coil-pin welding machine by CSM MACHINERY automatically welds coils to terminal pins after the manual assembly of the two units. The operator loads the components onto the walking beam conveyor, which individually transfers them to the welding station and the unloading point. A pneumatic alignment device located beneath the electrode ensures welding spot precision and repeatability, optimizing productivity.

The concrete advantages that make the difference

independent of operator skill.

consistently at a well-defined point.

in the work area due to automation.

Discover all the machine details

WALKING BEAM TO TRANSFER THE PREASSEMBLED TERMINAL PIN/COIL

from the loading position to the welding station. After welding the parts are offloaded into a stainless-steel container.

WORKING TABLE MADE IN STAINLESS STEEL

complete with device to unload and guide the terminal pin/coil assembly on the walking beam.

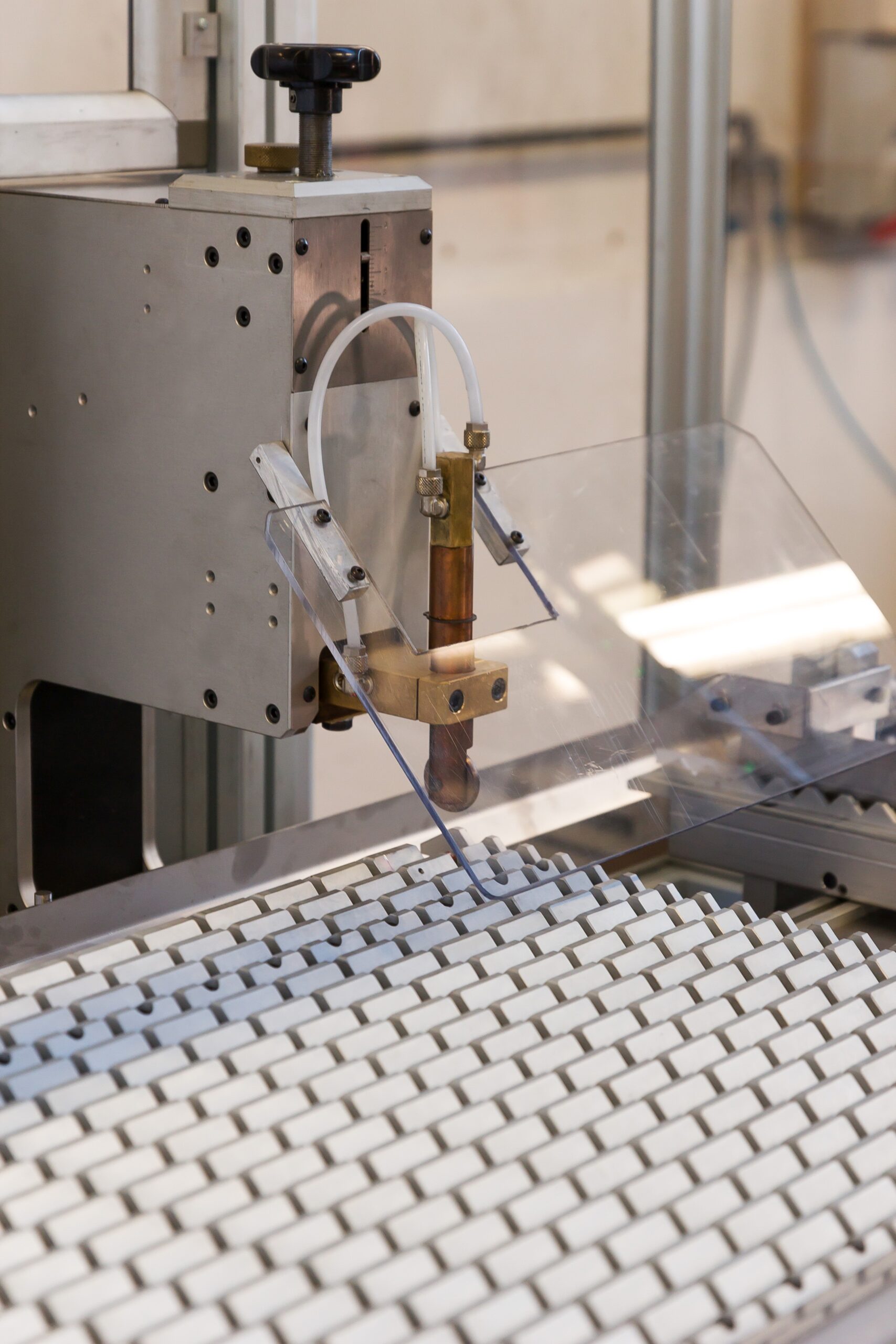

PNEUMATIC DEVICE TO ALIGN THE TERMINAL PIN/COIL ASSEMBLIES

under the welding electrode to guarantee repeatability of the welding process (always at the same point) of the coil.

15 KVA SPOT WELDER

complete with process control.

Cycle time | sec. 3-4 |

Terminal pin length | mm 45-200 |

Terminal pin diameter | mm 2,5-4 |

Coil length | mm 50-1.200 |

Coil OD | mm 1,8-4 |

Power supply | to be defined |

Installed power | KVA 15 |

Pneumatic supply | Ate 6 |

Water supply | l/min 2 |

Welding machine | to be defined |

Dimensions | mm (a x b x h) 2325x1245x1770 |

Weight | kg 400 |

Set-up times | min. 2-3 |

Discover the other products in our range