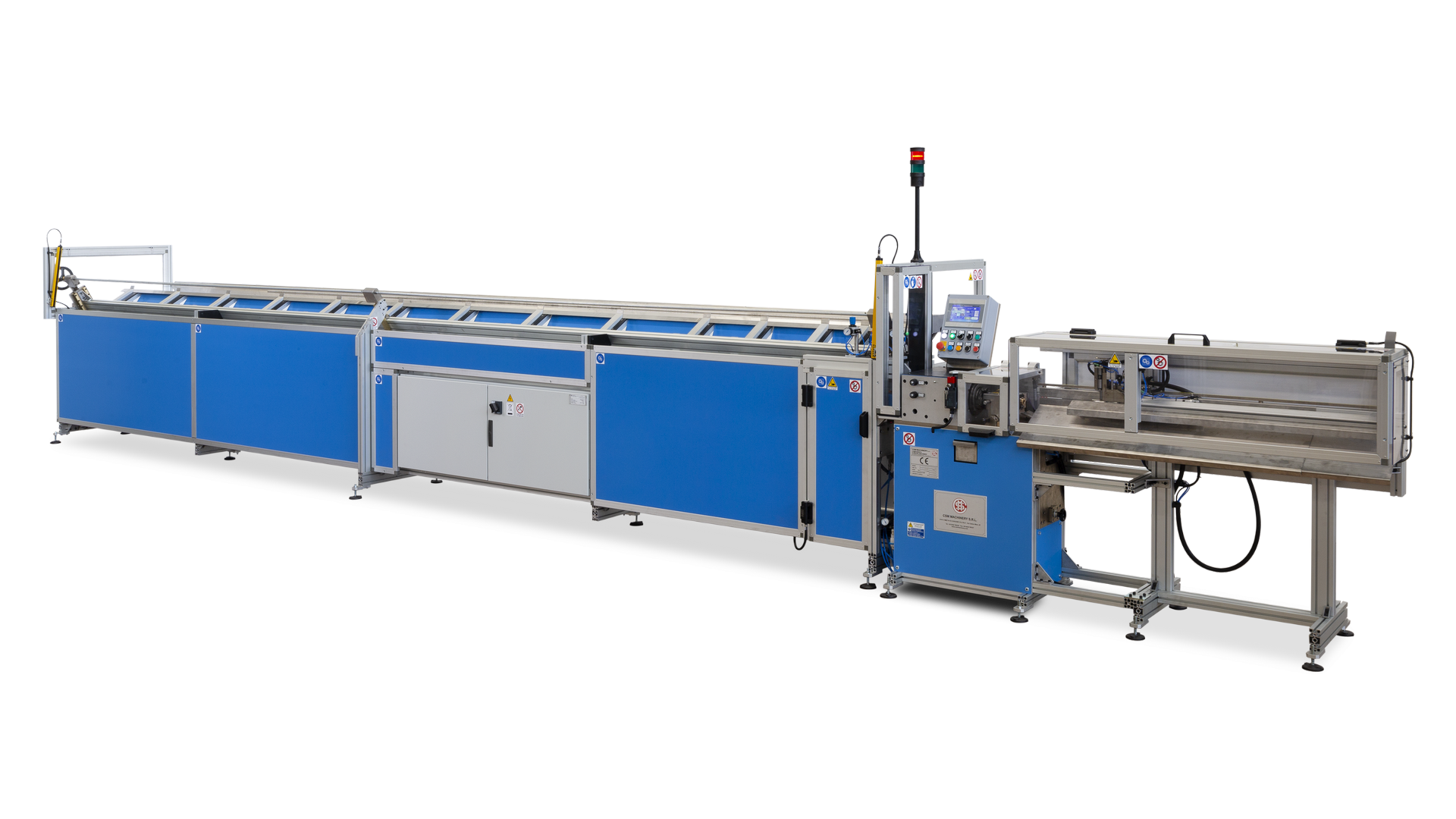

CSM MACHINERY designs and manufactures tube cutting lines for tubes in straight lengths with automatic feeding. This system is ideal for medium to large production batches and is designed to optimize overall production efficiency in terms of speed and scrap reduction.

With the automatic version of the machine, you simply load the tubes onto the feeder: the machine then autonomously handles loading, handling, length optimization, and part unloading.

The concrete advantages that make the difference

Discover all the machine details

INCLINED LOADER

AUTOMATIC FEEDER VIA MOTORIZED ROLLS

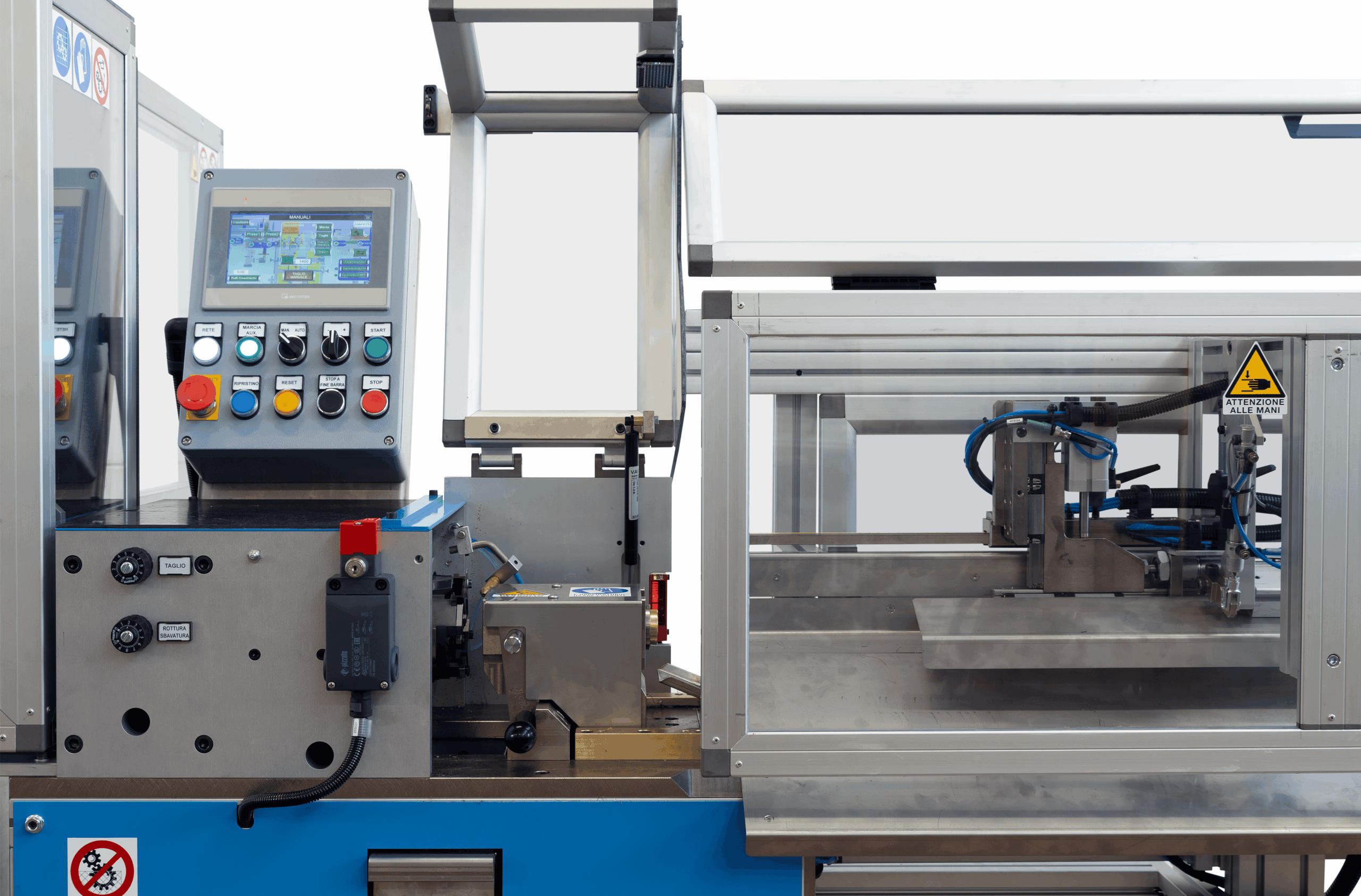

CUTTING UNIT

UNLOADER with mechanical stop to set the cutting length

SCRAP UNLOADING AREA

Short pieces are unloaded here as well

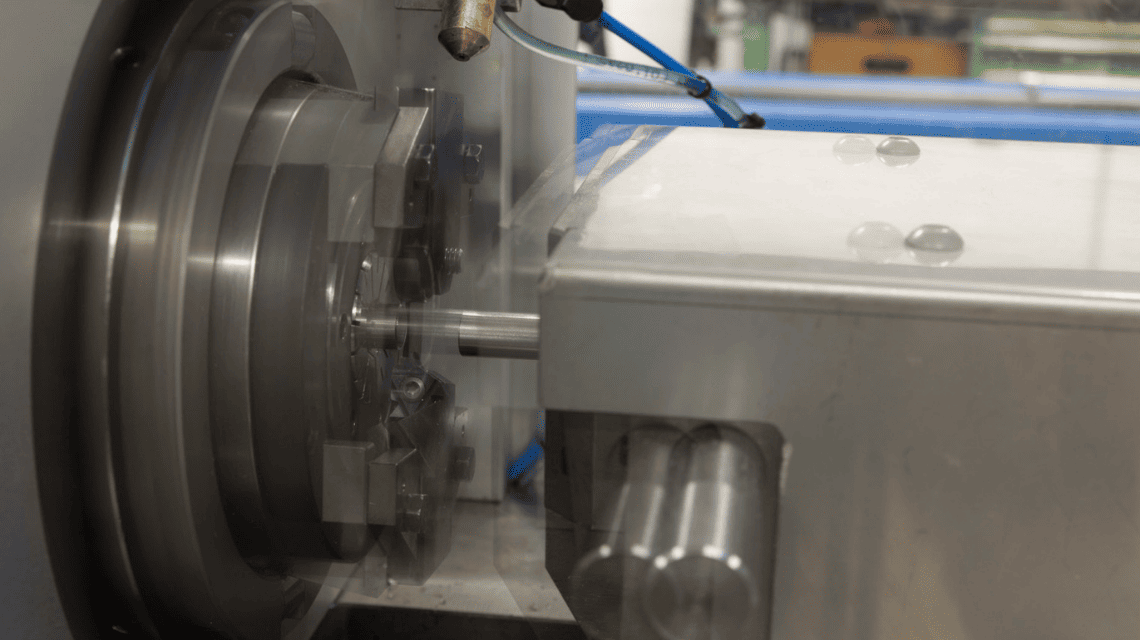

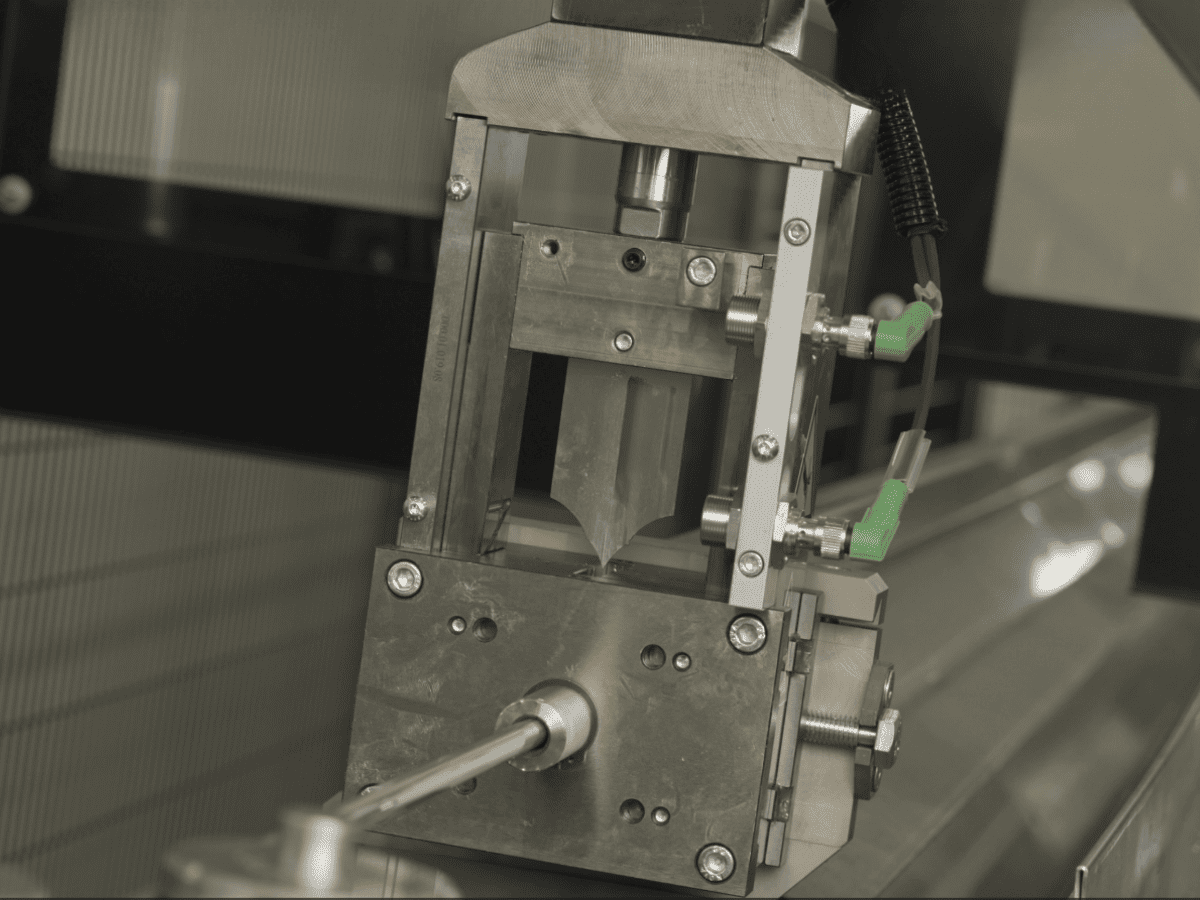

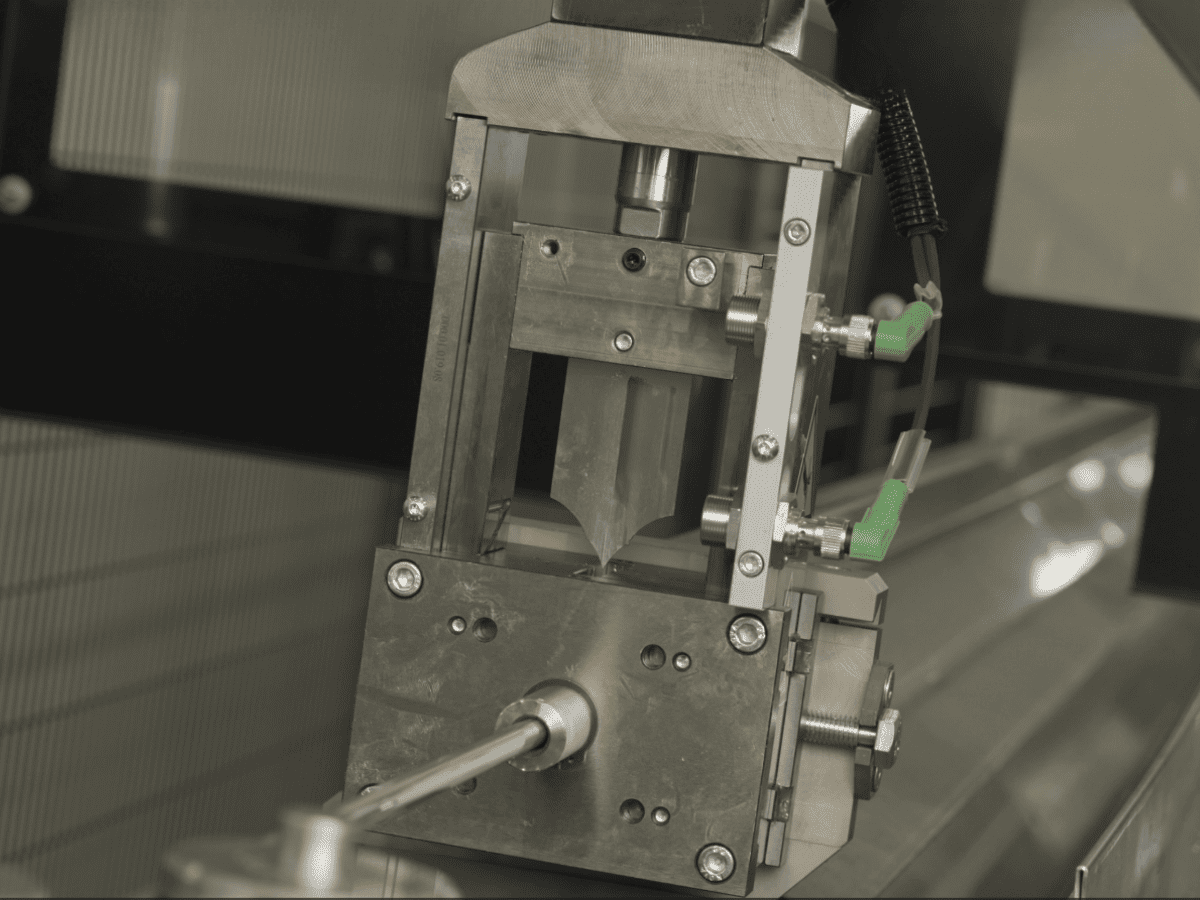

The score and pull-apart system is designed to overcome the problems presented with orbital cutting of a similar conception but realized using engraving wheels. In particular, this system allows the tube to be cut without deformations on the cut edge. The tube is not cut by blades that insist orthogonally on the wall of the tube, but by the combined action of a scoring tooth (made with a three-edged tool), which progressively removes material along a circular section of the cylindrical wall, thinning it, and a clamp that detaches the tube segment.

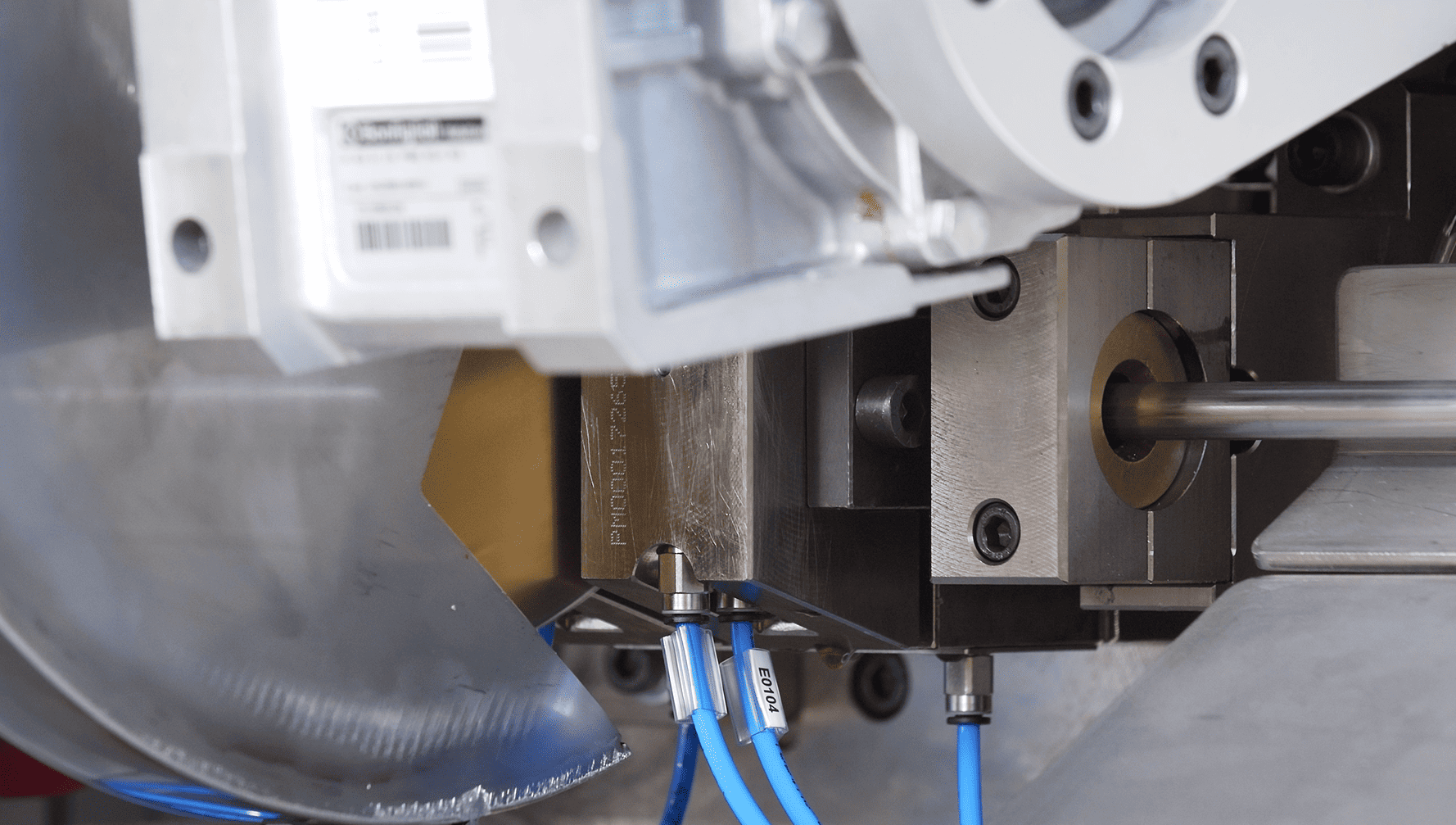

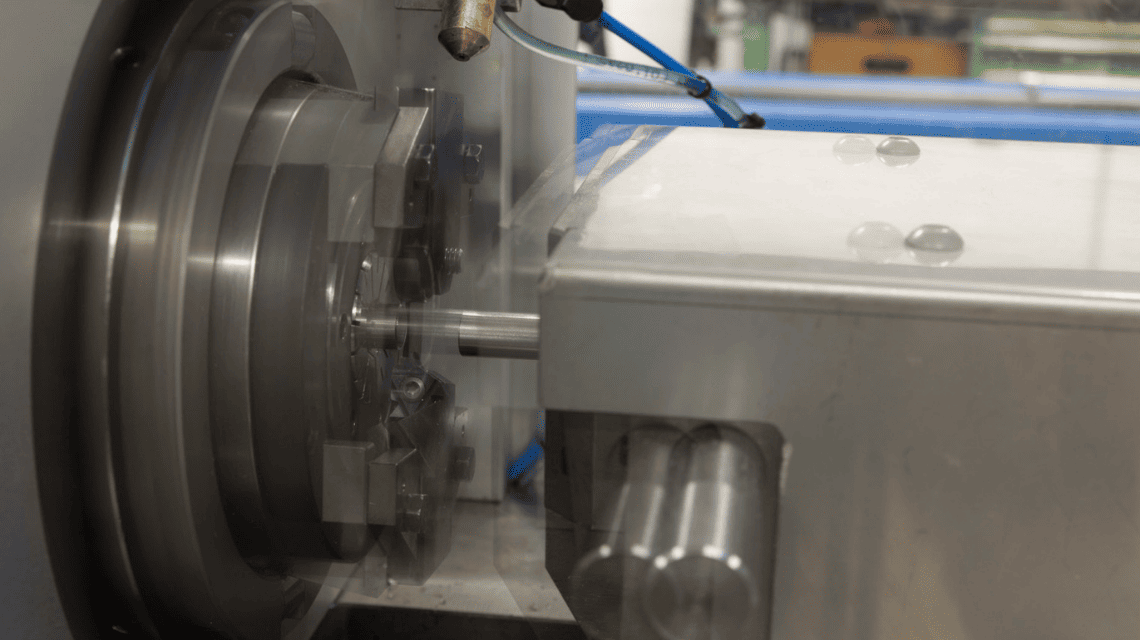

The saw cutting system incorporates a high-resistance circular blade that rotates at high speed to perform rapid and clean cuts. This technology offers the capabilities to manage different types of tube thickness, as well as different materials, with the precision of ninety-degree cuts. Furthermore, thanks to the robust materials and the cutting technique, the tool’s lifespan is extended, ensuring sustained durability and reliability.

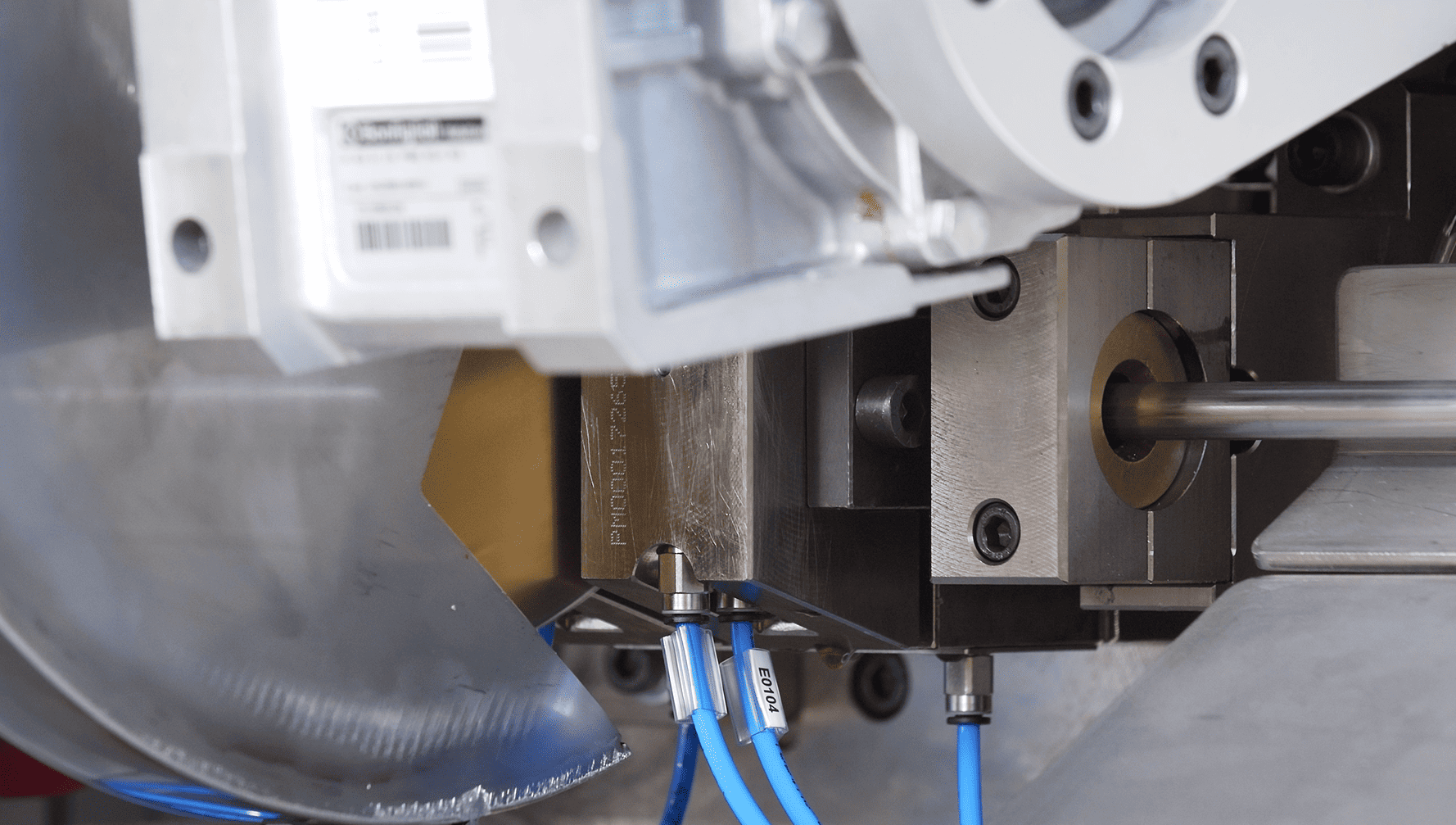

Guillotine cutting lines are designed for producing custom-sized tubes with the internal diameter calibrated at both ends and customized lengths. This type of system is primarily selected for medium to large-scale production, ensuring rapid cutting diameter changeovers. The subsequent punching operation, used to eliminate the “heart-shaped” distortion caused by the cut, can be performed manually via a punching gun or automatically with a punching transfer system downstream of the tube cutting.

The score and pull-apart system is designed to overcome the problems presented with orbital cutting of a similar conception but realized using engraving wheels. In particular, this system allows the tube to be cut without deformations on the cut edge. The tube is not cut by blades that insist orthogonally on the wall of the tube, but by the combined action of a scoring tooth (made with a three-edged tool), which progressively removes material along a circular section of the cylindrical wall, thinning it, and a clamp that detaches the tube segment.

The saw cutting system incorporates a high-resistance circular blade that rotates at high speed to perform rapid and clean cuts. This technology offers the capabilities to manage different types of tube thickness, as well as different materials, with the precision of ninety-degree cuts. Furthermore, thanks to the robust materials and the cutting technique, the tool’s lifespan is extended, ensuring sustained durability and reliability.

Guillotine cutting lines are designed for producing custom-sized tubes with the internal diameter calibrated at both ends and customized lengths. This type of system is primarily selected for medium to large-scale production, ensuring rapid cutting diameter changeovers. The subsequent punching operation, used to eliminate the “heart-shaped” distortion caused by the cut, can be performed manually via a punching gun or automatically with a punching transfer system downstream of the tube cutting.

A single solution, double power: it easily changes from score & pull-apart system, ideal for precision and speed on pipes of different sizes and thicknesses, to circular saw cutting to tackle tubes with even greater diameter. Maximum flexibility and productivity in one machine!

Tube Materials | Steel, stainless steel, copper, aluminum |

Tube wall thickness | mm 0,3 - 1,0 |

External tube diameter (to be defined) | mm 6 - 22 |

Max. tube cutting length | mm 6100 |

Cutting length | To be defined (mm) |

Cutting length tolerance up to 1500 mm | mm ±0,8 |

Cutting length tolerance between 1500 mm and 4300 mm | mm ±1 |

Automatic loader capacity with 7.5 mm tube diameter | pcs. 50 |

Available space in the loader hopper | mm 440 |

Minimum cutting length | mm 100 |

Minimum scrap length per bar (external tube diameter: > 10 mm) | mm 65 |

Minimum scrap length per bar (external tube diameter: < 10 mm) | mm 340 |

Installed power | kW 3 |

Voltage | 400 V/3 fasi/50 Hz |

Pneumatic supply | bar 6 |

Setup time when changing diameter | min. 10 - 15 |

Discover the other products in our range