CSM MACHINERY has extensive experience in coil preparation and is able to propose a number of solutions for pin-coil welding. According to the required production rates, these devices feature coil-pin-plug assembly units with manual, semi-automatic, or fully automatic function.

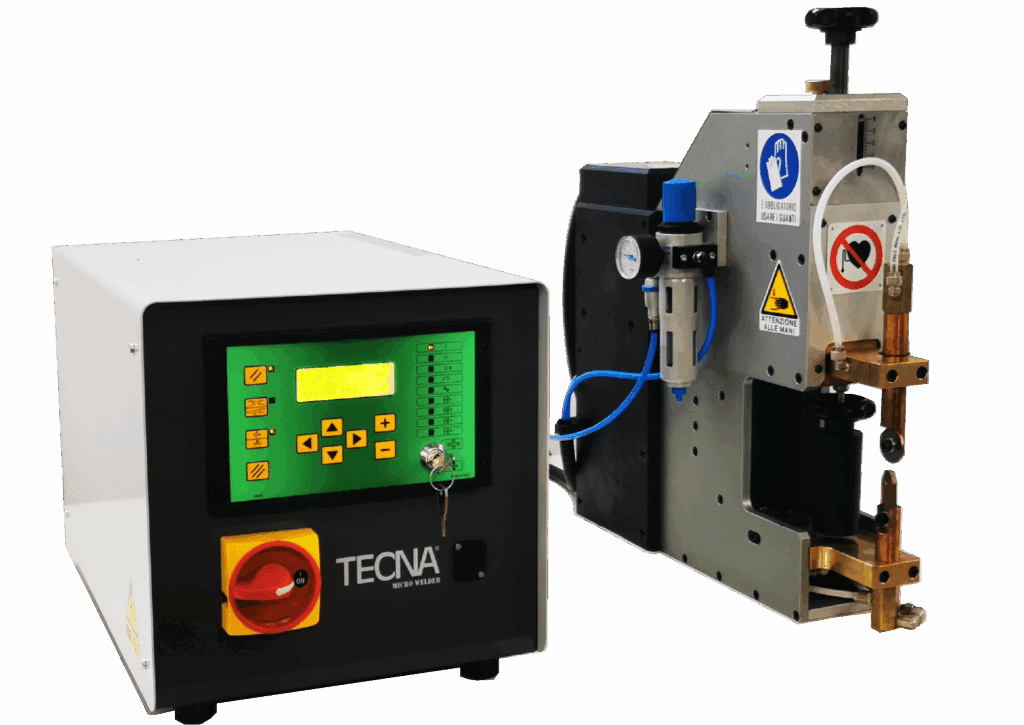

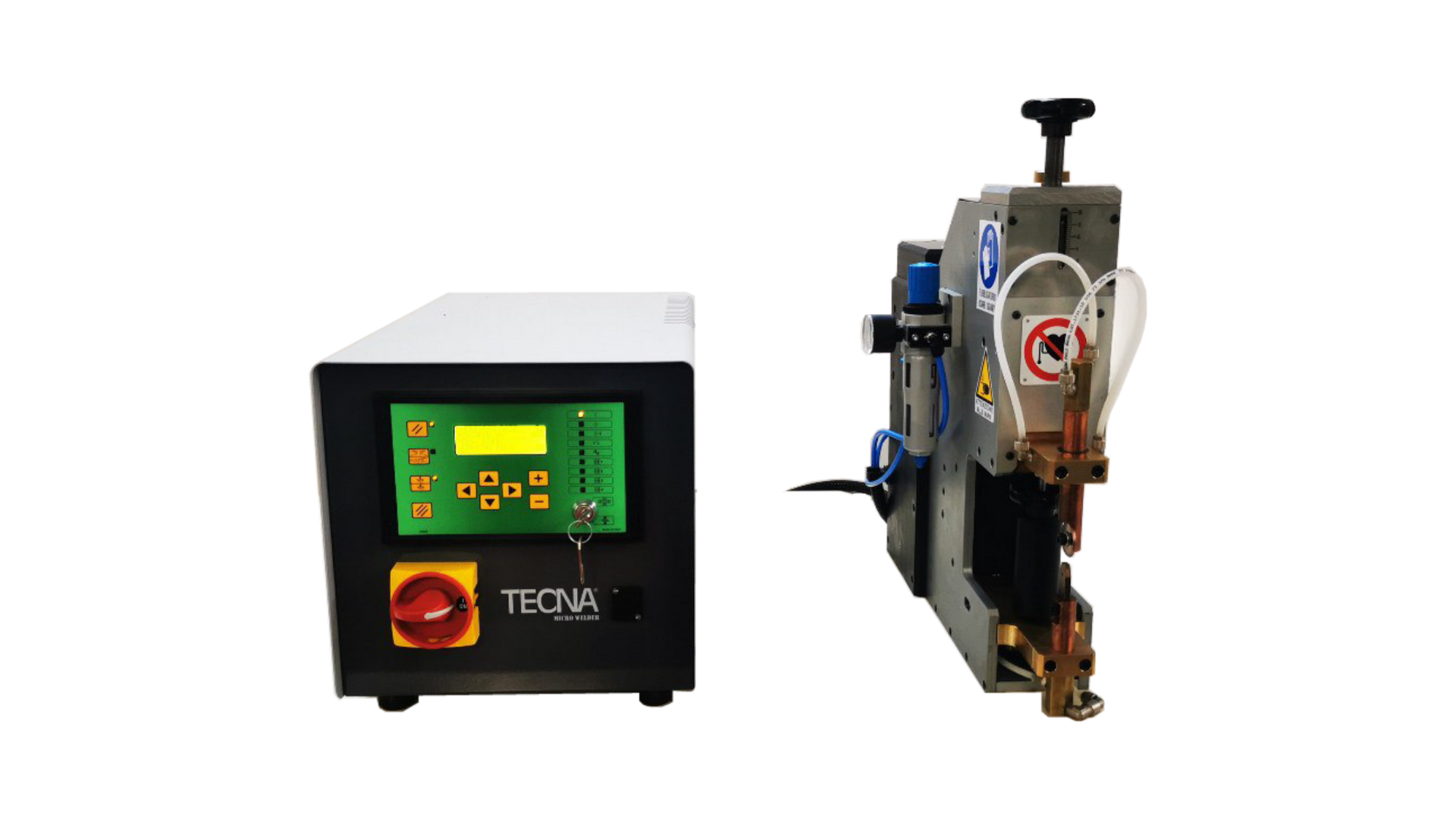

The manual spot welder is designed for attaching spirals to terminal pins, this is the ideal machine for small-volume production batches. Because it operates in a fully manual mode, the weld quality is entirely contingent on the operator. This machine is equipped with a precise electronic welding control to ensure proper weld parameter adjustment according to variations in the type and diameter of the wire being welded.

The concrete advantages that make the difference

each configurable with 32 parameters.

Discover all the machine details

ELECTRONIC CONTROL SYSTEM

Controlled diodes power group (S.C.R.) and transformer made of silicon sheets, with nominal power 15 KVA, single-phase, completely water-cooled and impregnate in epoxy resins.

FRAME IN ALUMINUM FUSION

for the housing of the whole welding group.

ELECTRONIC CONTROL WITH THE POSSIBILITY TO SET UP TO 300 WELDING PROGRAMS WITH UP TO 32 PROGRAMMABLE PARAMETERS FOR EACH PROGRAM

The system is complete with:

2 WATER-COOLED ELECTRODE HOLDER ARMS

CCD COPPER ELECTRODES

Cycle time | 3 - 4 sec. |

Terminal pin length | 45 - 200 mm |

Terminal pin diameter | 2,5 - 4 mm |

Coil length | 50 - 1200 mm |

Coil outer diameter | 1,8 - 4 mm |

Power supply voltage | To be defined (V) |

Installed power | 15 kVA |

Pneumatic supply | 6 Ate |

Cooling water | 2 l/min |

Welding unit | To be defined |

Dimensions | 2325 x 1245 x 1770 mm (L x W x H) |

Weight | 400 kg |

Machine setup time | 2 - 3 min. |

Discover the other products in our range