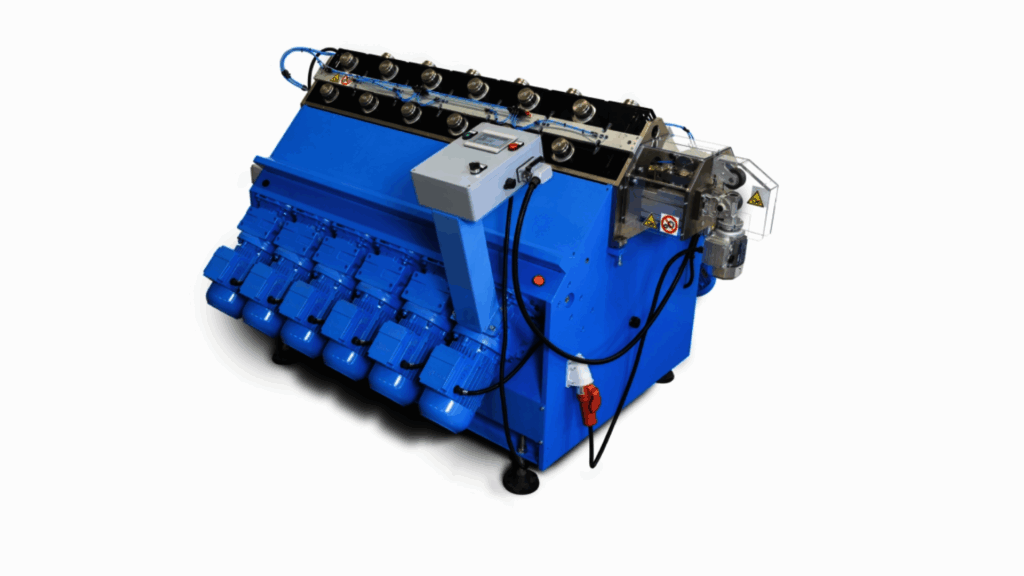

The length measurement unit from CSM MACHINERY is an innovative device designed to accurately assess the length of electric heating elements as they exit the rolling mill. This system provides immediate feedback on whether the elements conform to the specified length range.

The process starts with the use of a wheel encoder that precisely measures the tube’s length as it passes through the unit; the obtained values are displayed in real-time on the control panel.

In fact, the system is equipped with a user-friendly PLC touch-screen interface that allows for easy configuration of the desired minimum and maximum length parameter, within which the electric heating elements must fall.

Therefore, it is possible to verify the actual measurement of the element and whether it is longer or shorter than the established range on the screen.

Finally, the system features a real-time indicator light system: the green light with the “OK” signal instantly indicates elements that meet the preset length specifications. On the other hand, the red light with the “KO” signal immediately identifies elements that fall outside the established range.

The length measurement unit can be integrated into any type of rolling mill. Positioned at the exit end, it can also be connected to CSM’s automatic unloading device. This integration streamlines the various steps involved in the diameter reduction phase, significantly increasing efficiency.

ADVANTAGES

- Precise length measurement: the wheel encoder ensures accurate measurement of electric heating element lengths as they exit the rolling mill. This minimizes the potential for human error and guarantees greater uniformity in the final product.

- Immediate conformity verification: the system’s ability to compare the measured length with a predefined range (minimum and maximum) and immediately signal conformity (“OK” green light) or non-conformity (“KO” red light) enables real-time quality control.

- Flexible configuration: the PLC touch-screen offers an intuitive interface for easily setting and modifying the desired length range parameters, adapting to various production specifications.

- Waste reduction: immediate identification of non-conforming heating elements allows for timely intervention in the production process, minimizing the creation of defective parts and, consequently, material waste.

- Simple integration: the unit’s ability to integrate seamlessly into any type of rolling mill by positioning it at the exit point makes it a versatile and easily adoptable solution for existing production lines.

- Discharge process optimization: the potential connection with CSM’s automatic unloading device further automates the diameter reduction phase, accelerating the entire workflow.

CSM MACHINERY’s measurement unit represents a significant advancement in optimizing the heating element production process, offering advantages in terms of precision, efficiency, waste reduction, and improved product quality.

Contact us to learn more about it!