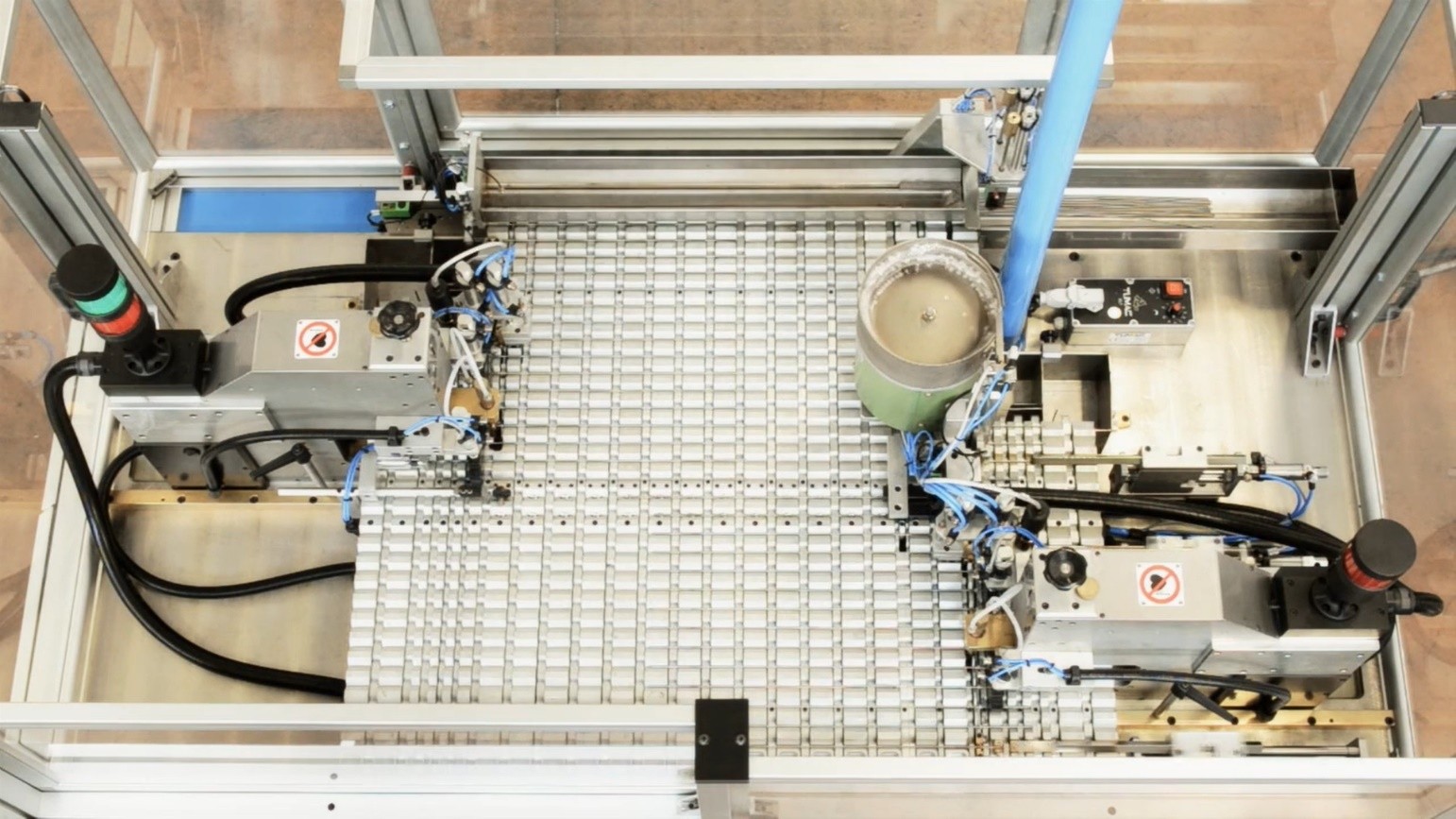

A single machine capable of performing three operations simultaneously: assembling the terminal pins to the spiral, mounting the plastic plug onto the lower pin and welding the spiral to the pins.

CSM MACHINERY’s automatic assembly machine is designed for producers who work with medium to large-sized product batches, as it allows for optimization of production time and costs.

The concrete advantages that make the difference

Discover all the machine details

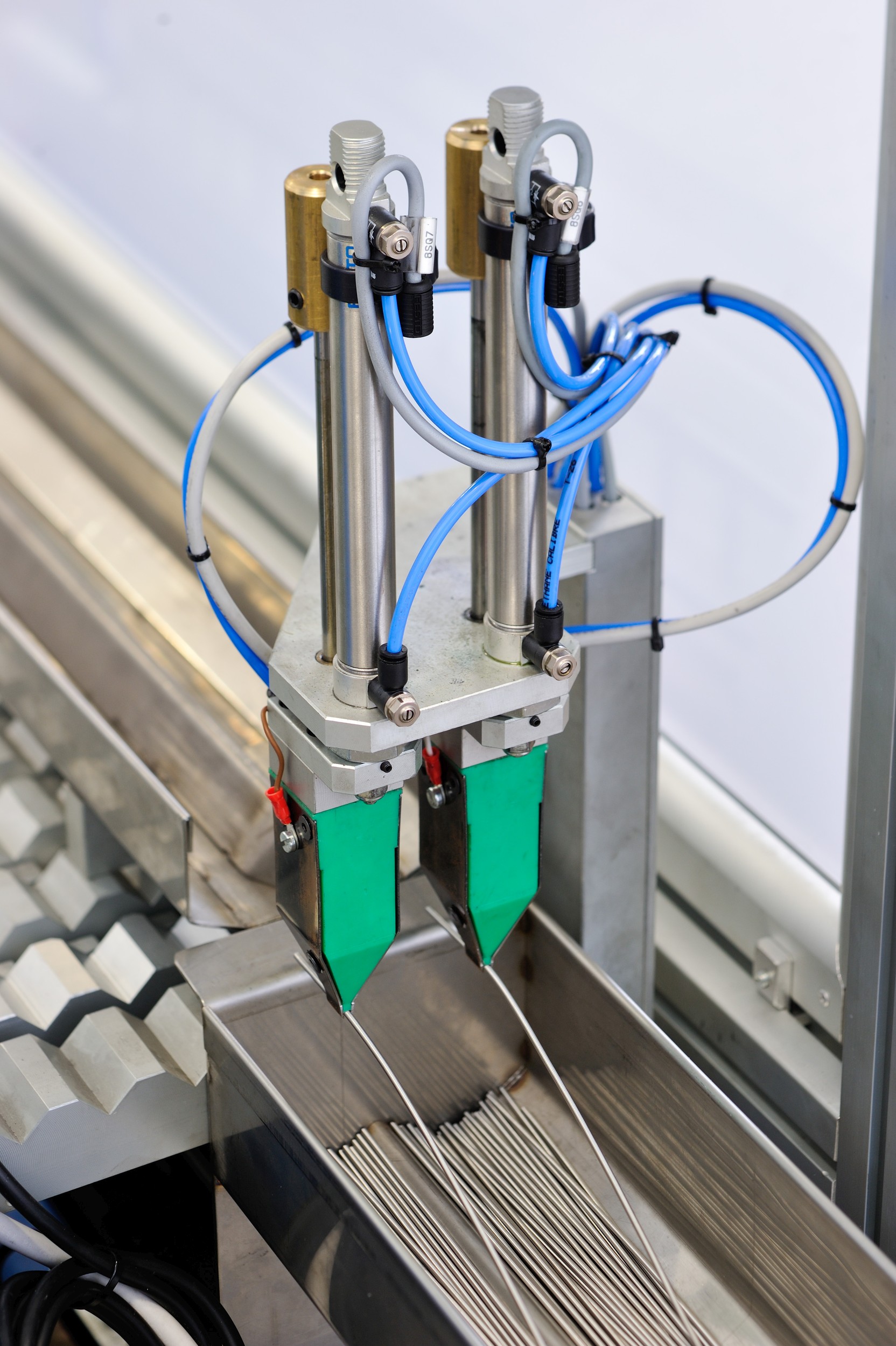

PIN-COIL WELDER WITH ELECTRONIC CONTROL AND THE POSSIBILITY TO SET UP TO 300 WELDING PROGRAMS WITH UP TO 32 PROGRAMMABLE PARAMETERS FOR EACH PROGRAM

The system is complete with: Approach of the electrodes – Setting of the welding current ramp – Setting of the current and of the welding duration – Setting of the holding current – Setting of the higher and lower limits of the welding current – Holding in pressure by cooling after the welding.

STAINLESS STEEL HOPPER

to put coils into position.

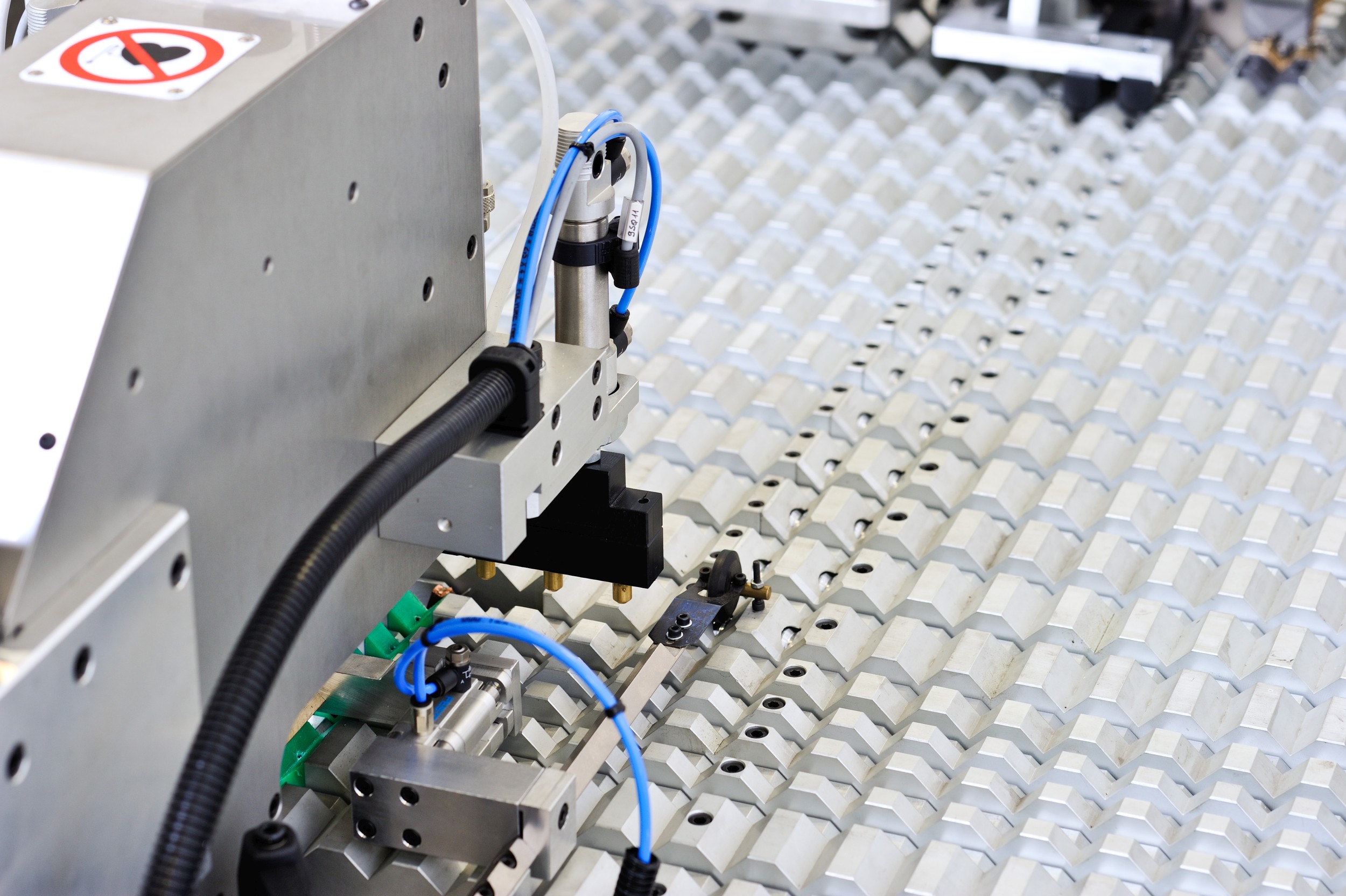

OPTIC SENSORS

to check the presence of coil in the transfer unit.

2 PINCERS WITH PNEUMATIC MOVEMENT

that collect and transfer two coils from the feeding hopper into the collecting hopper, by means of a d.c. motor.

FEEDER FOR LOWER PIN-PLUG ASSEMBLY

The station consists of an automatic vibrating feeder for plastic caps and an adjustable-stroke pneumatic pusher for insertion onto the pin.

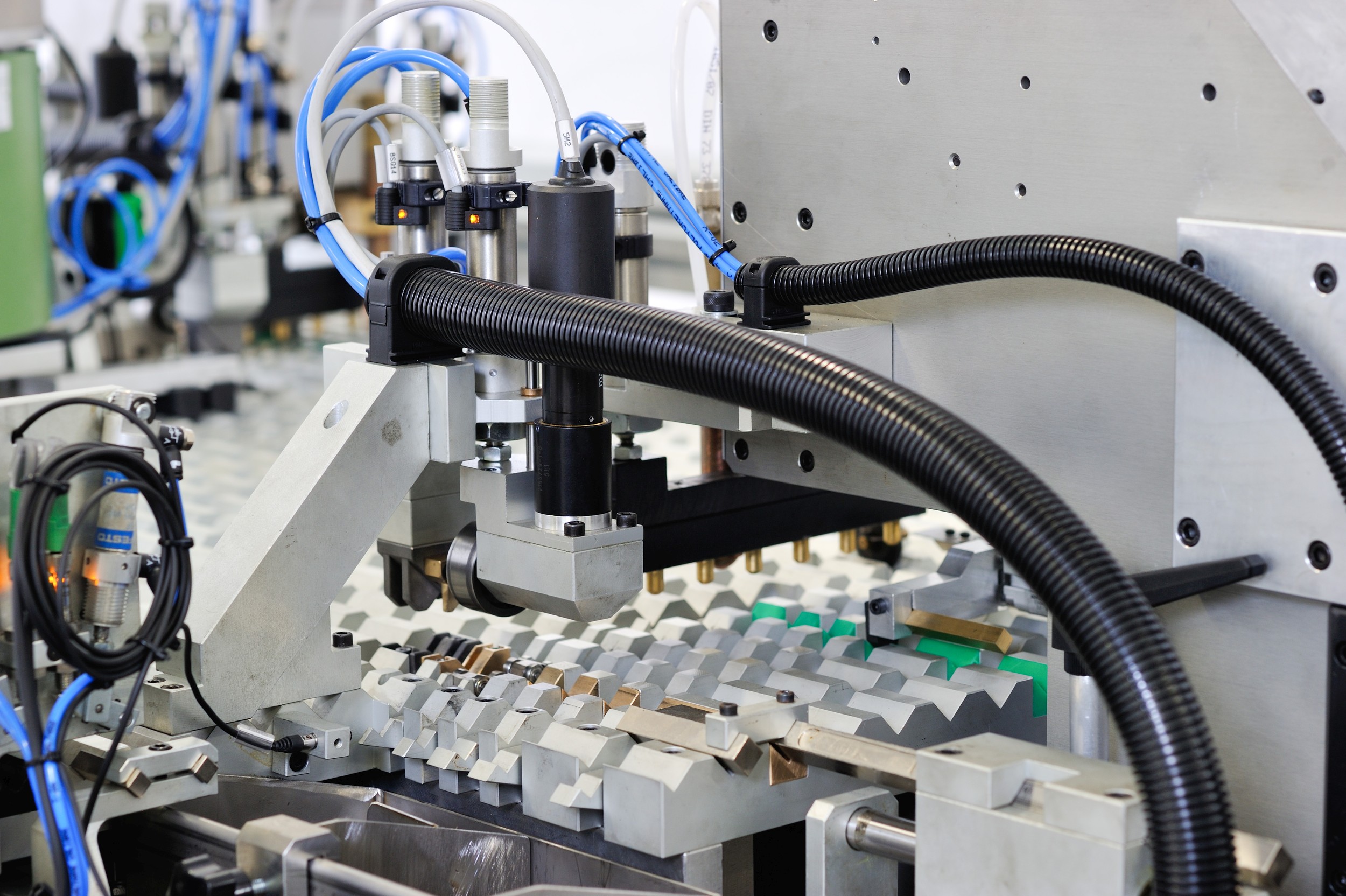

LINEAR TRANSFER

Pilgrim Step System with CNC-machined coil supports, having the function of receiving and perfectly aligning the individual components, coil and end pins, to transfer them to the assembly stations.

2 AUTOMATIC FEEDERS FOR TERMINAL PINS

The terminal pins are positioned in bunches in the feeding hoppers with all the tops facing the same direction. One pin is fed at each machine cycle and its presence is automatically checked on the transfer by a fibre-optic sensor.

COLLECTING HOPPER

Hopper for collecting the two coils and sequentially discharging them into the assembly transfer.

ALIGNMENT DEVICE

Device for aligning the coil on the transfer conveyor for the assembly of the upper terminal pin.

PIN-COIL WELDER WITH ELECTRONIC CONTROL AND THE POSSIBILITY TO SET UP TO 300 WELDING PROGRAMS WITH UP TO 32 PROGRAMMABLE PARAMETERS FOR EACH PROGRAM

The system is complete with: Approach of the electrodes – Setting of the welding current ramp – Setting of the current and of the welding duration – Setting of the holding current – Setting of the higher and lower limits of the welding current – Holding in pressure by cooling after the welding

2 AUTOMATIC FEEDERS FOR TERMINAL PINS

The terminal pins are positioned in bunches in the feeding hoppers with all the tops facing the same direction. One pin is fed at each machine cycle and its presence is automatically checked on the transfer by a fibre-optic sensor.

Cycle time of the machine (up to) | sec. 5 |

Terminal pin length | mm 5-200 |

Terminal pin diameter | mm 2,5 – 3 |

Coil length | to be defined |

Coil diameter | mm 2 – 3 |

Minimum wire diameter | mm from 0,20 to 0,90 |

Welding power | KVA 16 |

Power supply | 3 PH x 400V + N + G |

Pneumatic supply | Ate 6 |

Machine dimensions | mm 2.500x2.500x1.400 |

Discover the other products in our range