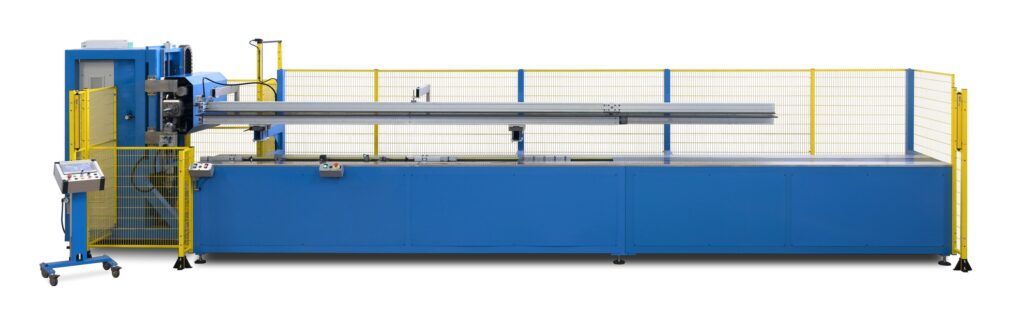

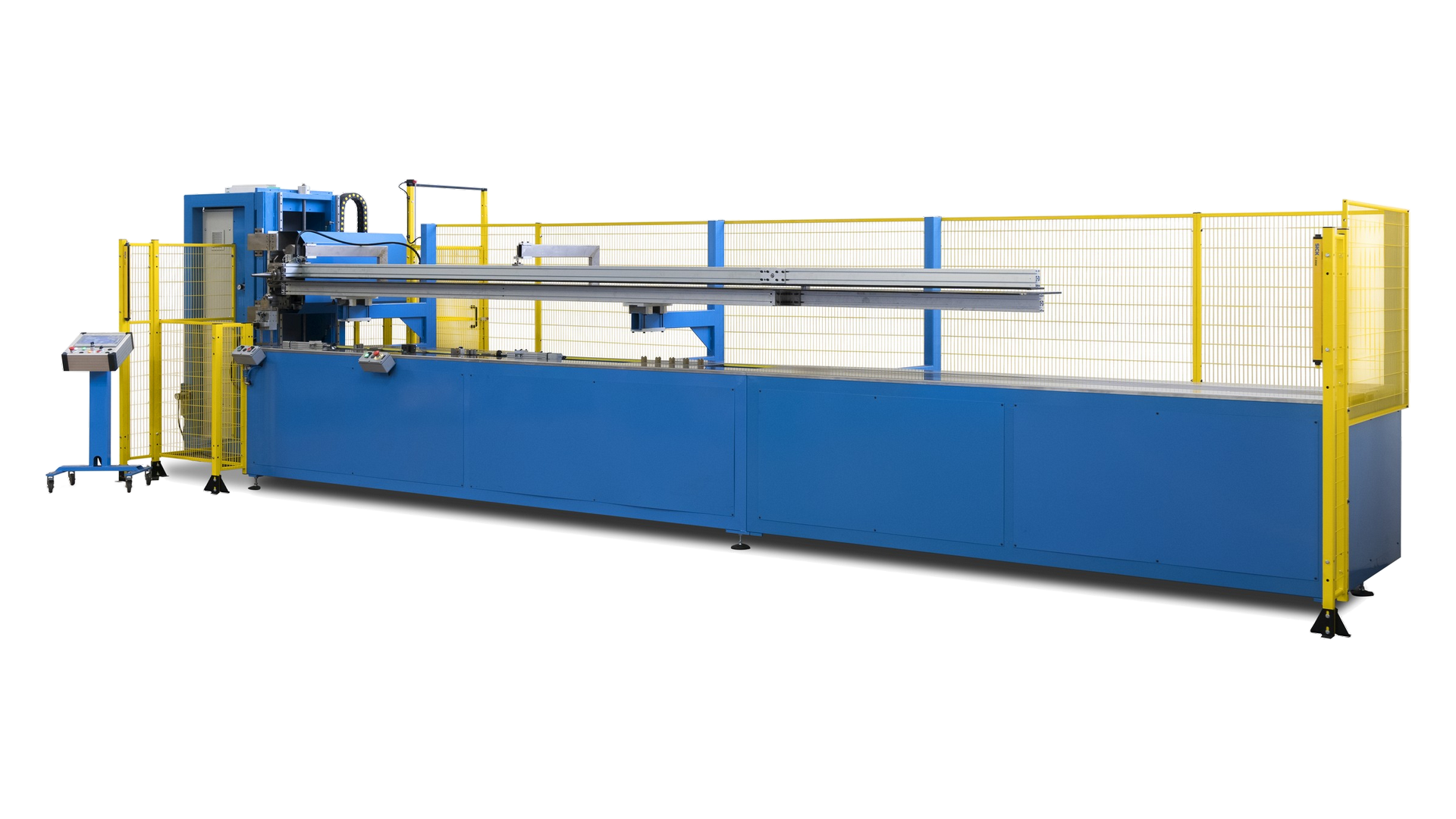

The CSM MACHINERY circular element bending machine combines the precision of numerical control (NC) with the flexibility of software and tools, enabling users to produce a wide variety of circular elements. Its primary feature is its ability to adapt to diverse production needs through the simple replacement of the forming head, making it an extremely versatile tool for creating various models of heating elements.

This bending machine isn’t limited to standard circular elements; it can also produce conical elements, resulting in a flexible machine that makes it suitable for numerous applications.

The concrete advantages that make the difference

to allow for elements with a central long leg to be formed.

with element support in terms of height.

with to exchange data and save or load work programs.

for circular type heating elements.

Discover all the machine details

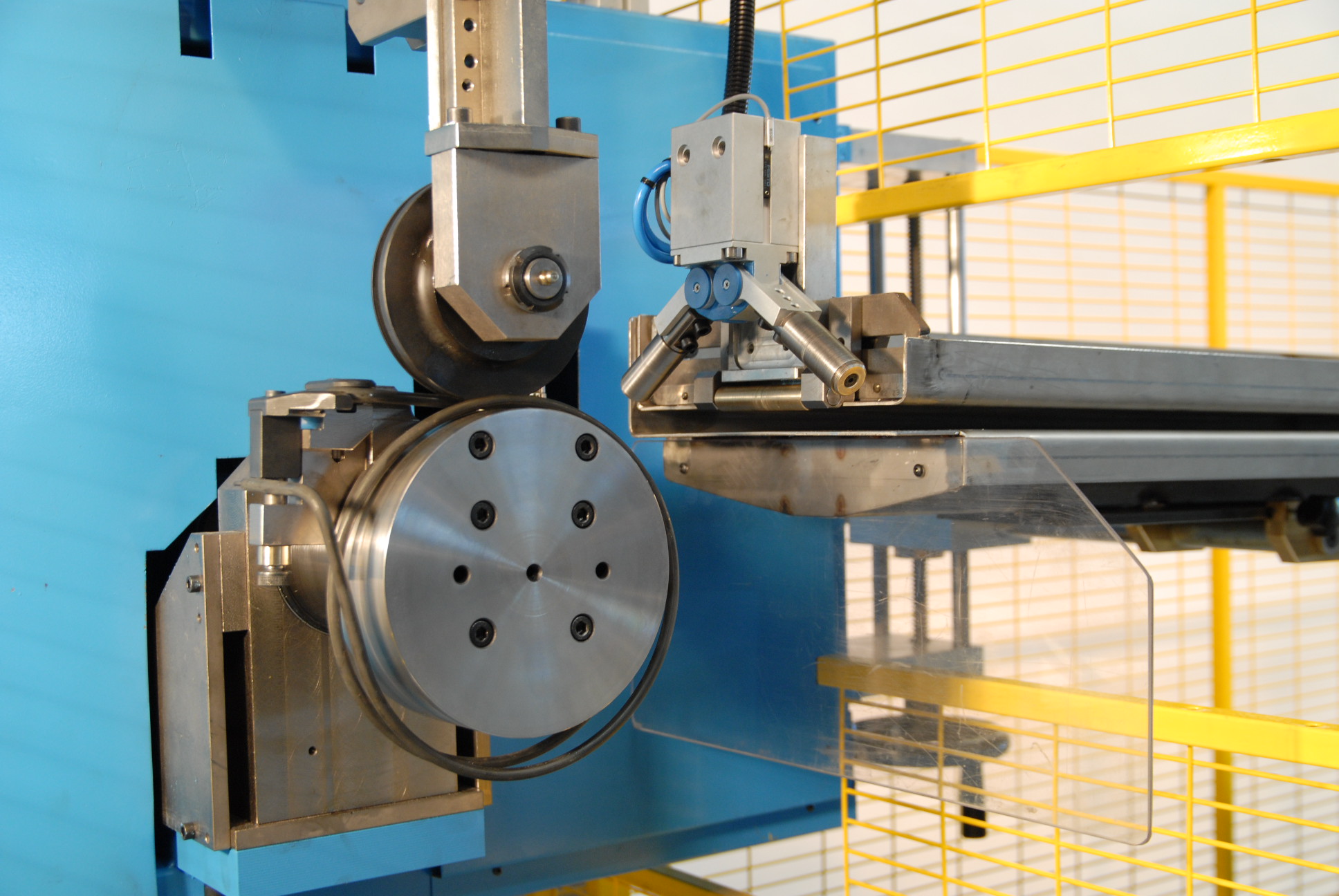

2 ROTATING UNITS FOR HEATING ELEMENT WINDING

ADJUSTABLE SPEED GEARMOTOR

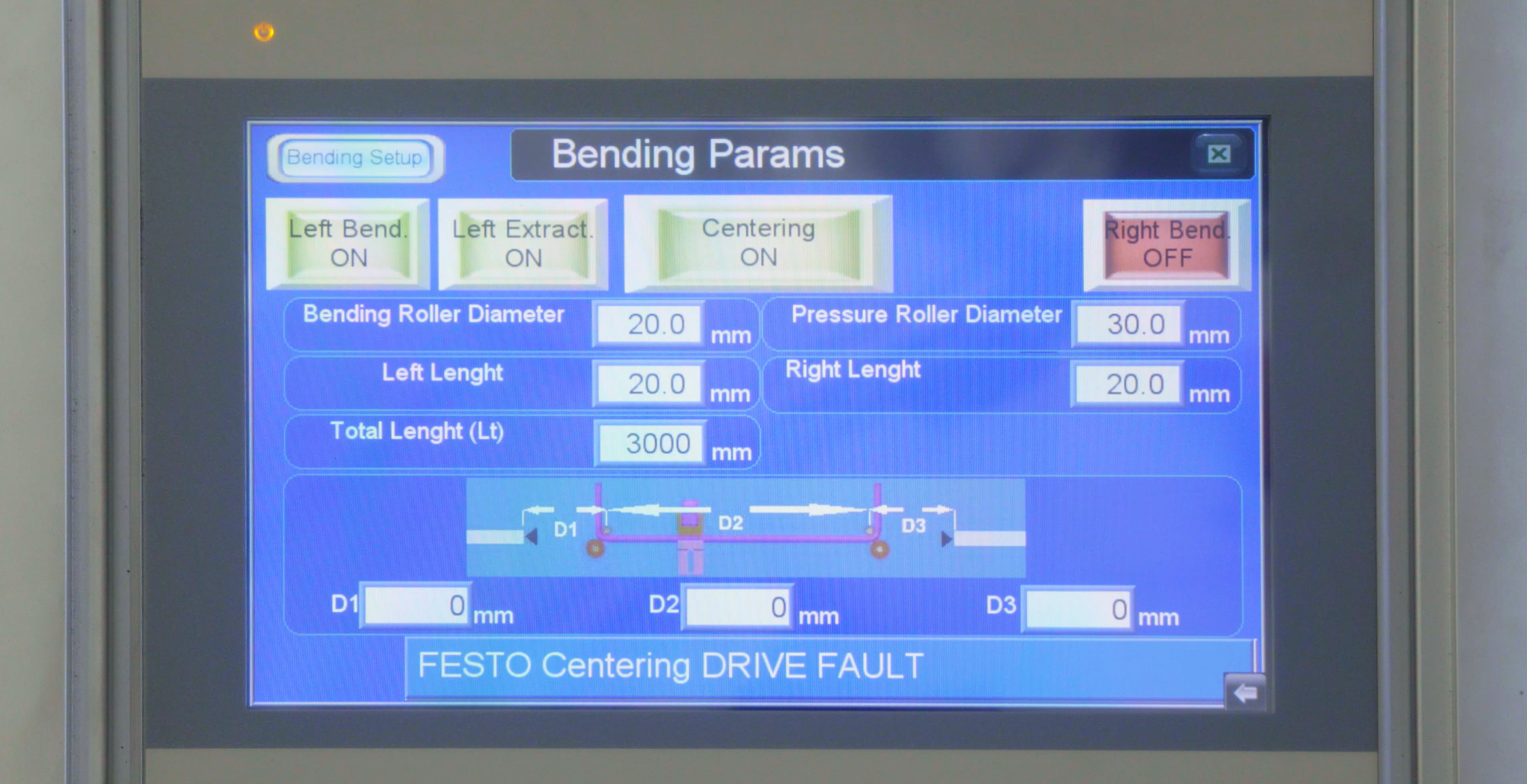

with the possibility to programm the required number of turns and the rotation degrees for the last turn.

NOTE

Different shapes are done by changing the tooling which is always specific to a particular drawing. Some circular shapes may allow the usage of the same tooling when only the number of turns vary.

OPERATOR CONTROL PANEL

Maximizing productivity is no longer enough. To support any competitive advantage, companies must achieve resilience, faster innovation, higher customer satisfaction, more-engaged workforces without incurring into an excessive amount of costs.

Power supply | V to be defined |

Pneumatic supply | Bar 6 |

Heating element diameter | mm 6,25-12 |

Heating element length | mm to be defined |

Max. arbour diameter (where element will be wound) | mm 600 |

Max. stroke of the coiling head (max spread of element along arbour) | mm 500 |

Set-up at the change of the model | min. 10-20 |

Discover the other products in our range