CSM MACHINERY has developed a specialized machine for bending finned heating elements. Offering an optimal balance of cost-effectiveness, performance, and adaptability. The finned heating element bending machine stands out for its ease of use and flexibility. Allowing it to handle a wide range of finned heating element sizes and shapes.

The machine is designed to perform precise and uniform bends, ensuring the highest quality of the finished product. Its robust and reliable construction guarantees a long service life, minimizing maintenance costs and downtime.

The concrete advantages that make the difference

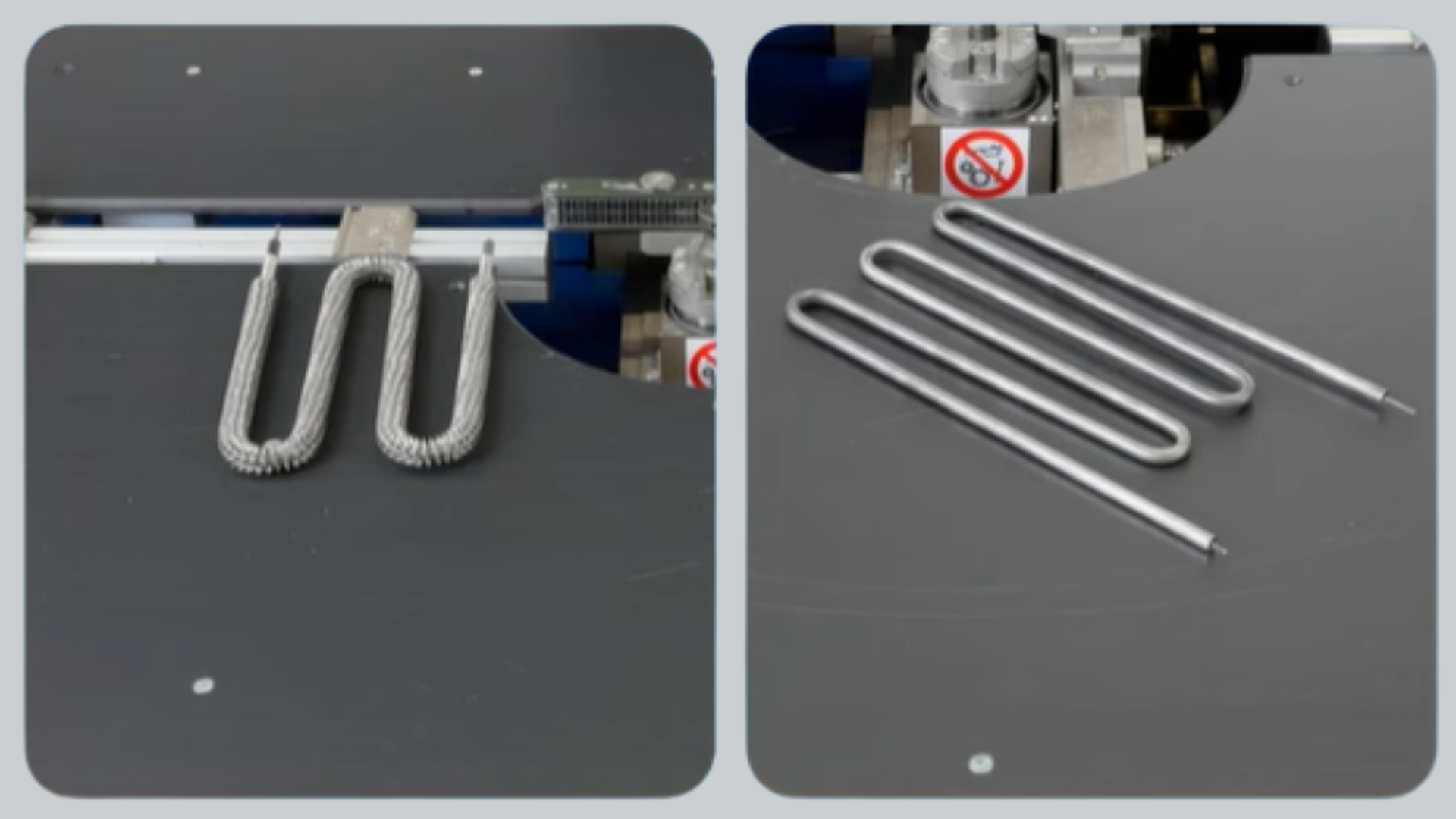

for a wide range of diameters, shapes, and bending angles.

for both finned and and unfinned tubular heating elements.

of producing tight-radius bends.

Discover all the machine details

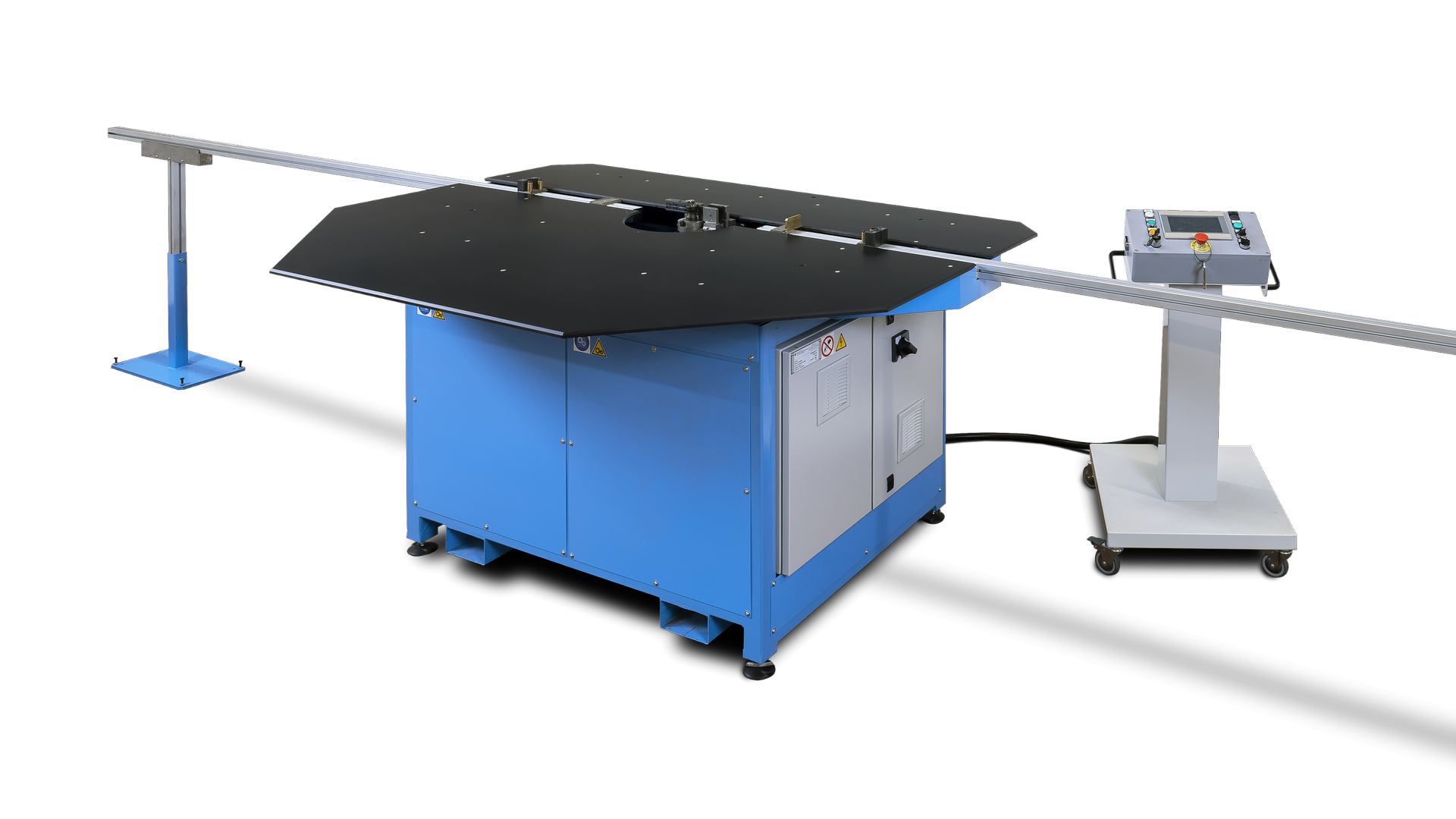

ELECTRO WELDED AND PAINTED STEEL BASEMENT

HORIZONTAL WORKING TABLE

for supporting the element during bending

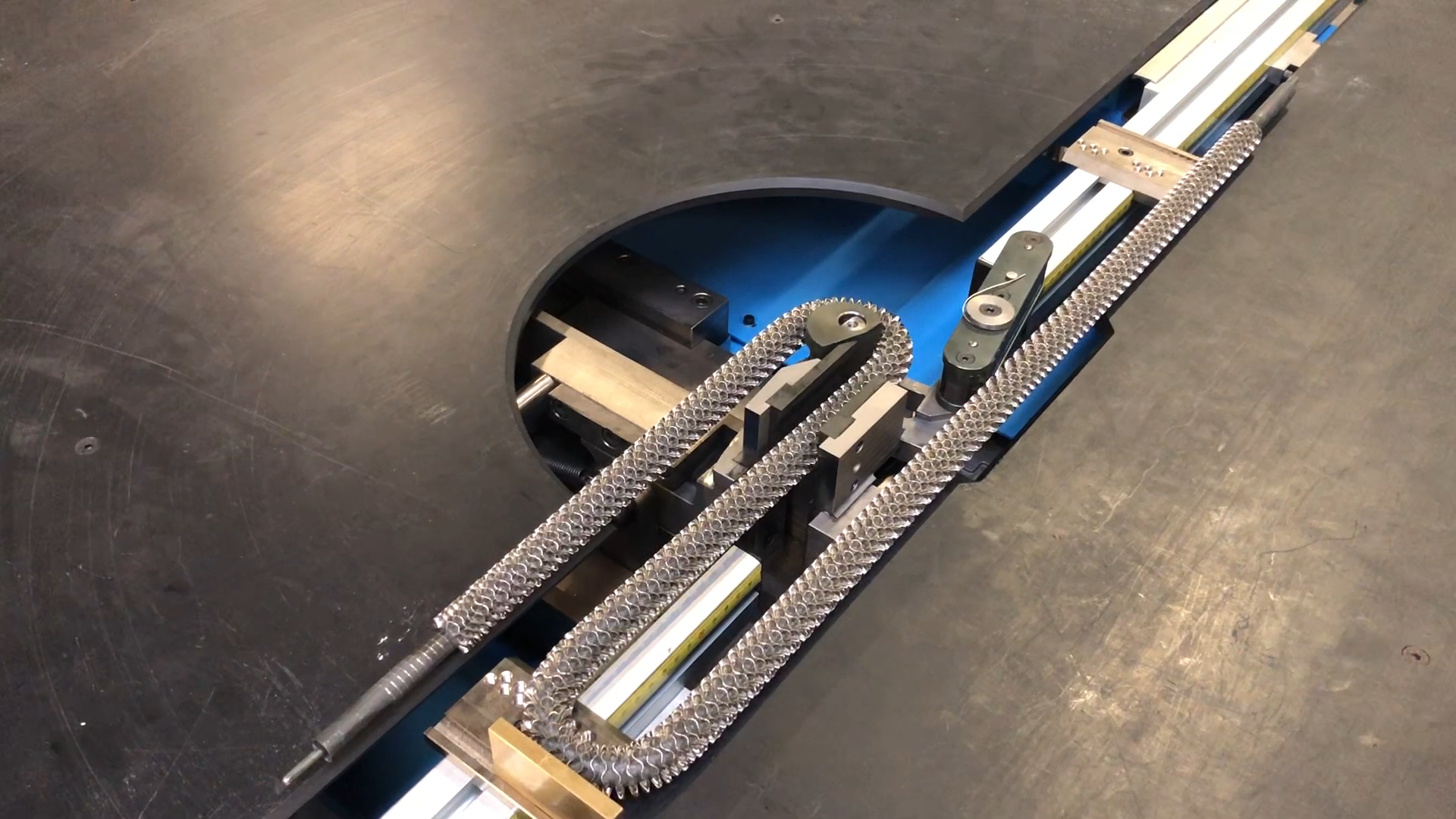

ROTATING BENDING UNIT

Programmable bending unit up to 200°.

PNEUMATIC FIXED CLAMP

for holding the element during the bending cycle.

CENTRALIZE DEVICE

Centralizer for the element to be bent, complete with metric rules.

ELECTRIC CABINET

Electric cabinet complete of programming unit and 2 hand push button console.

NOTE

The machine is equipped with tooling for a tubular heating element diameter, a finned heating element diameter, and a bending radius.

Utilizing a specific device, the machine is capable of forming small-radius bends in finned electric heaters.

Utilizing a specific device, the machine is capable of forming small-radius bends in finned electric heaters.

Element diameter | mm to be defined |

Maximum diameter finned element (element with fin “Dmax”) | mm reference to versions table |

Bending roll diameter (defined by the internal bend radius “Ri”) | mm to be defined |

Element per bending cycle | pz. 1 |

Set-Up Time * change length (with centralizer) | min. 2 - 4 |

* Change bending radius | min. 2 - 4 |

* Change diameter over fins | min. 4 - 5 |

* Change diameter of tube | min. 3 - 4 |

Programming | min. 2 - 3 |

Power supply | V to be defined |

Pneumatic supply | Ate 6 |

Installed power | KW 2 |

Discover the other products in our range