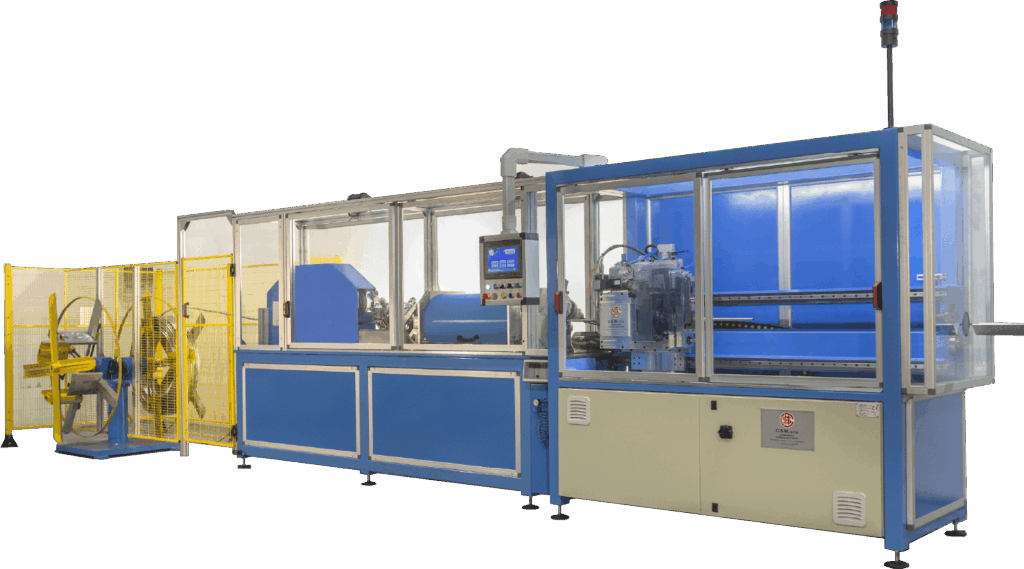

The automatic tube cutting system from coil is ideal for processing large product volumes. Coil processing requires the machine to be composed of several components, including decoiling and straightening units for aligning stainless steel tubes, as well as a cutting unit with a scoring and tearing system.

Once the feed speed, batch size, and cutting length are set directly on the operator interface, the machine starts operating autonomously.

The concrete advantages that make the difference

Discover all the machine details

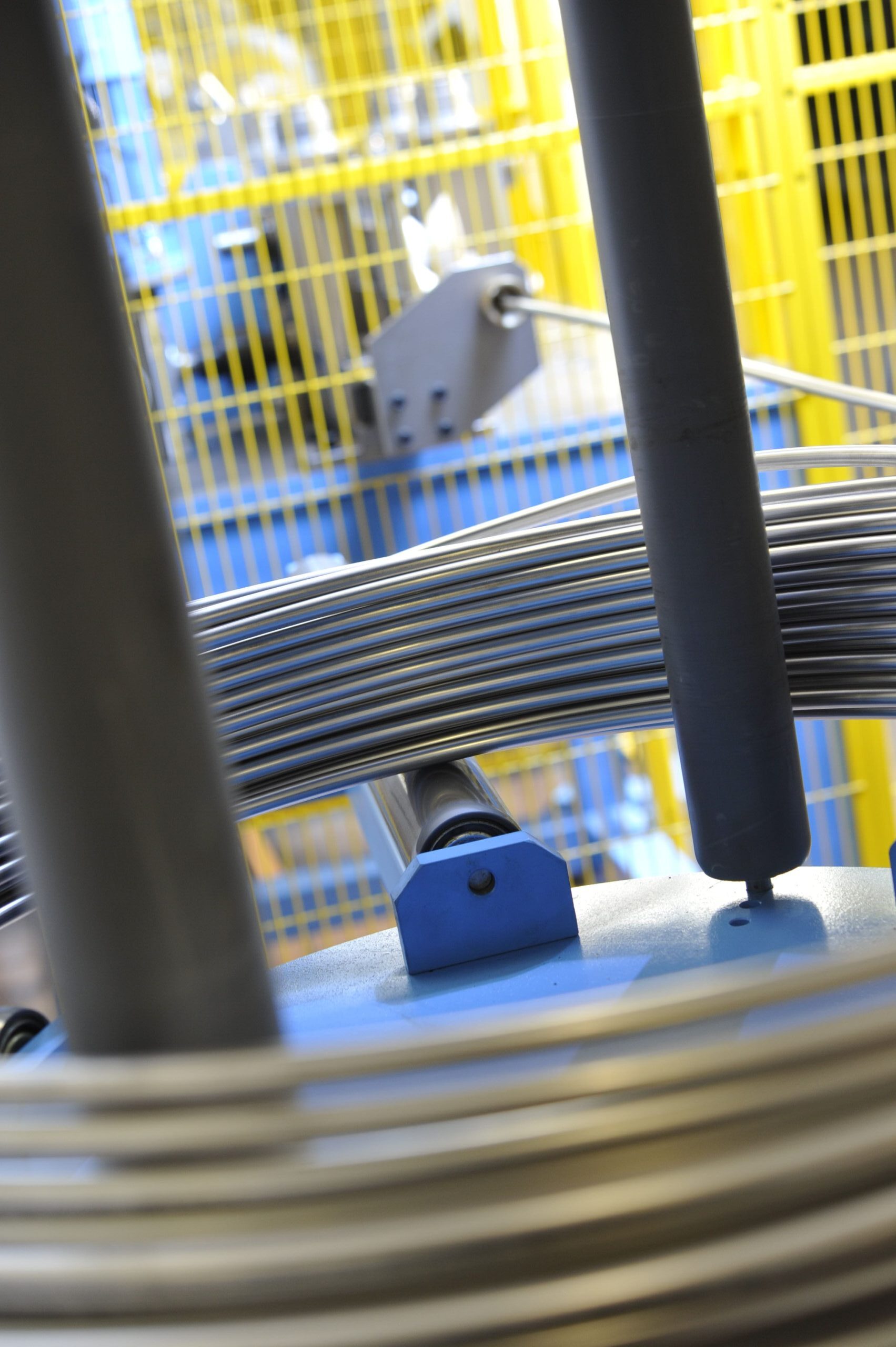

DOUBLE STRIP DE-REELER

with the possibility of including 2 coils of tube, to avoid stopping the machine during coil replacement, maintaining seamless operation.

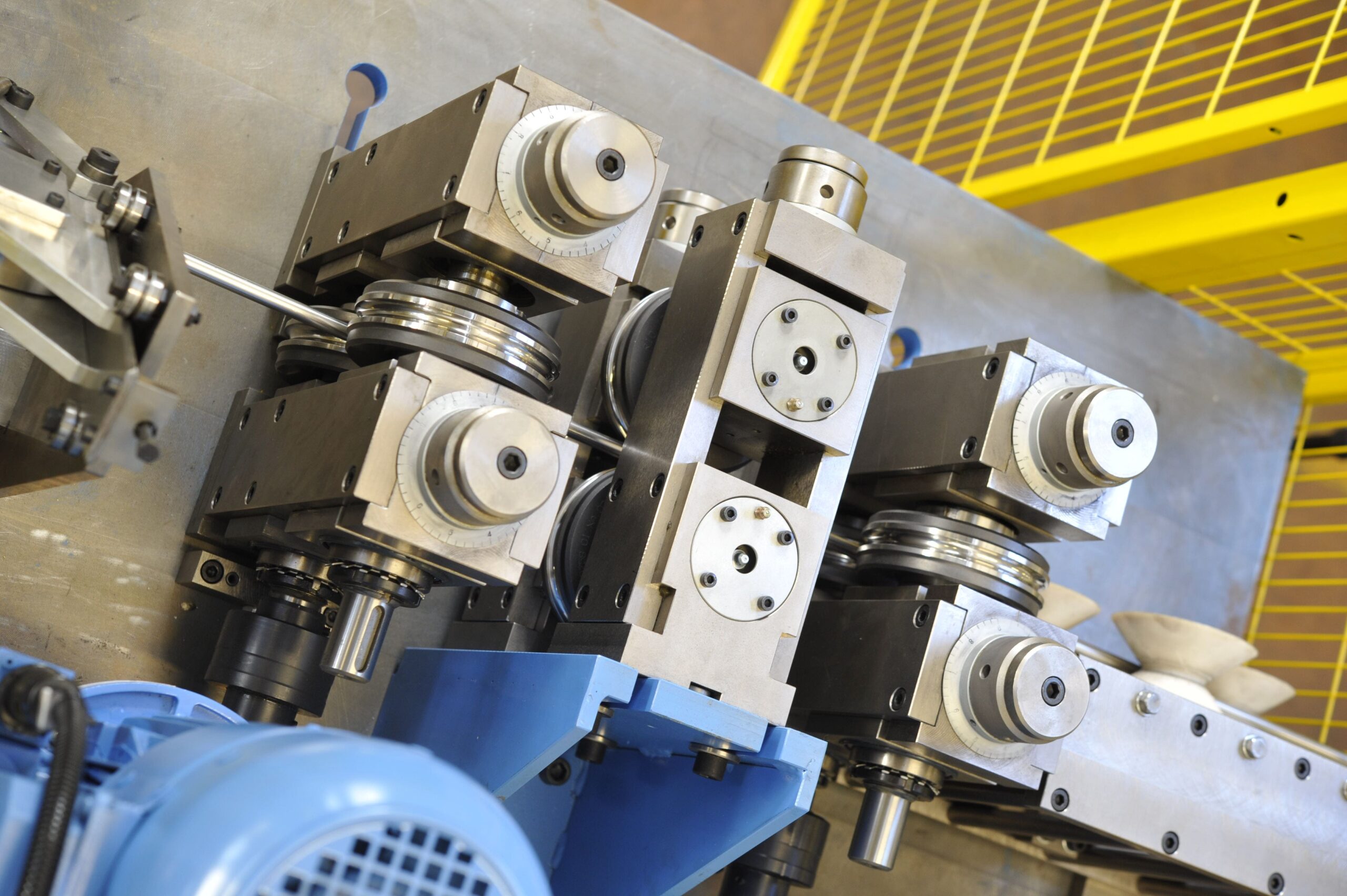

CALIBRATION SYSTEM

The machine is supplied with two calibration heads. The heads are idle. When various diameters of tube are to be processed, it is recommended to purchase additional calibration units complete of base, roll supports and rolls to minimize the change over time. Otherwise for each diameter change it is necessary to replace the rolls and guide bushes on the calibration system.

ELECTRIC CONSOLE

Electric cabinet and operator console complete with touch-screen display, where the operator can program length of tube to be cut, number of pieces to be cut, and line speed.

UNLOADING HOPPER

TRACTION SYSTEM (CATERPILLAR)

This device has two tracks rubber lined which pull the tube away from the de-reeler and push it through the calibration unit, into and through the straightening device. The top track can move up (open) or down (close or running mode) by means of a pneumatic cylinder. The pressure applied by the cylinder can be adjusted so as to suit the tube diameter and wall thickness. As a standard the top track is motorized but there is also the possibility to motorize the bottom track with a small modification.

STRAIGHTENER

Rotating straightener with 5 pairs of idle hyperbolic rolls.

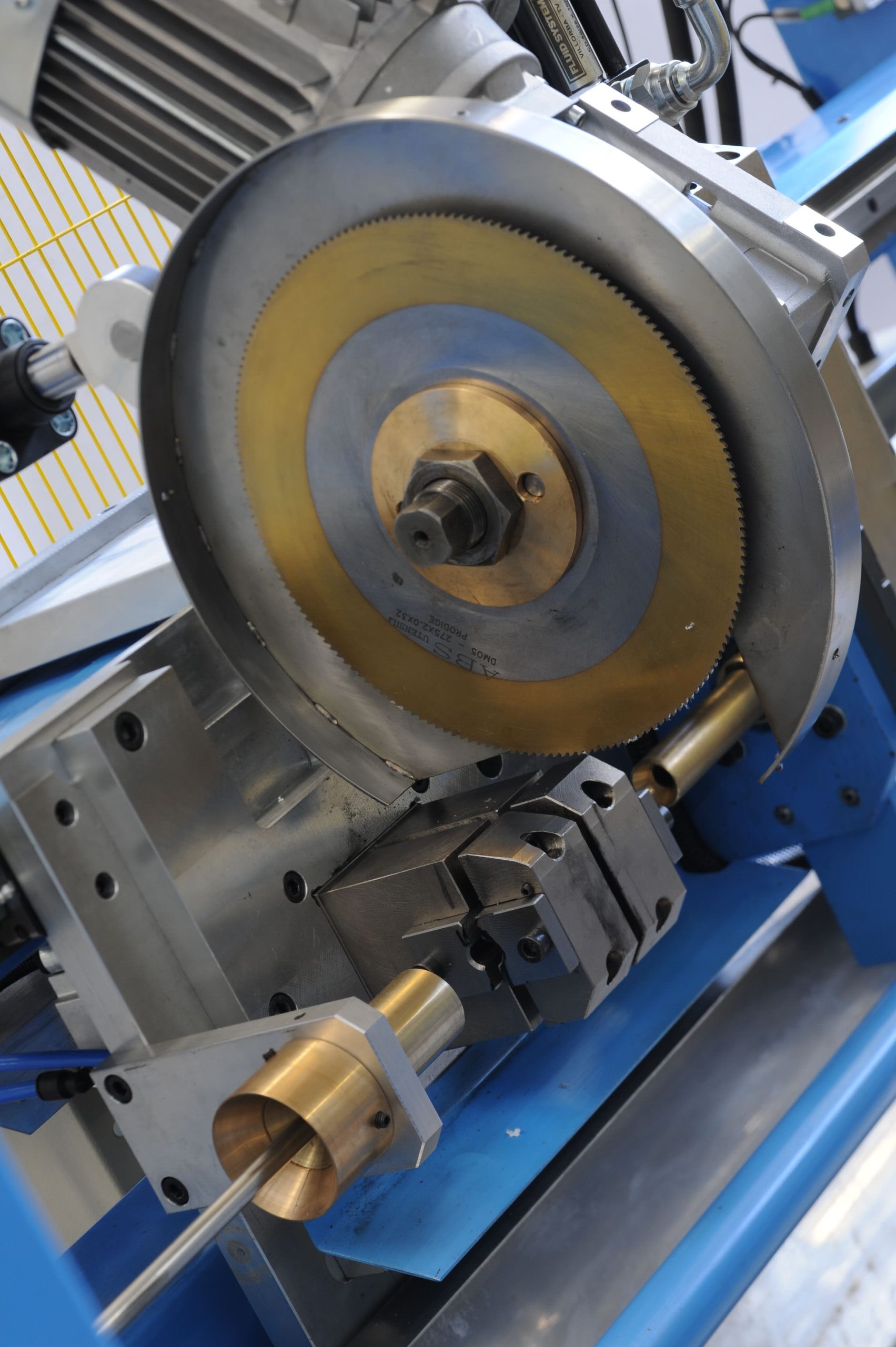

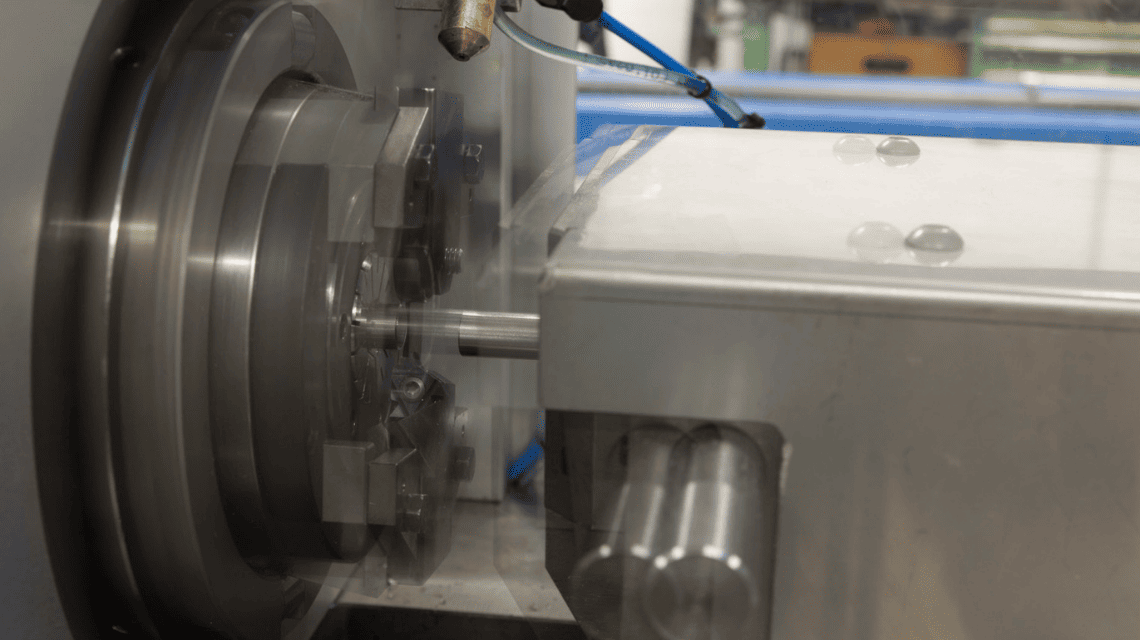

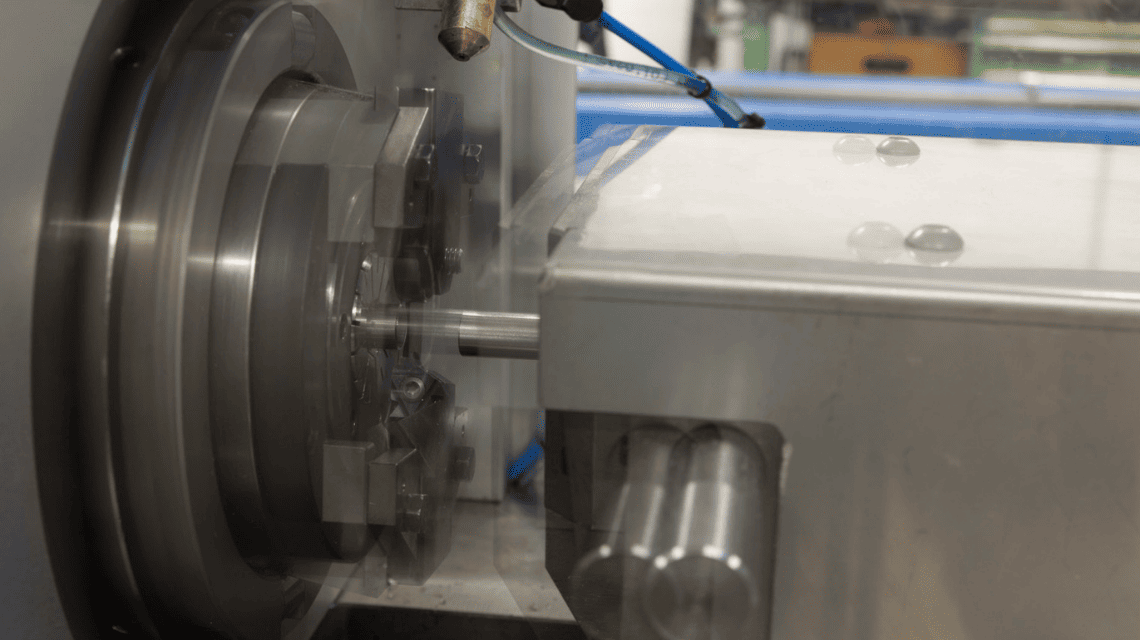

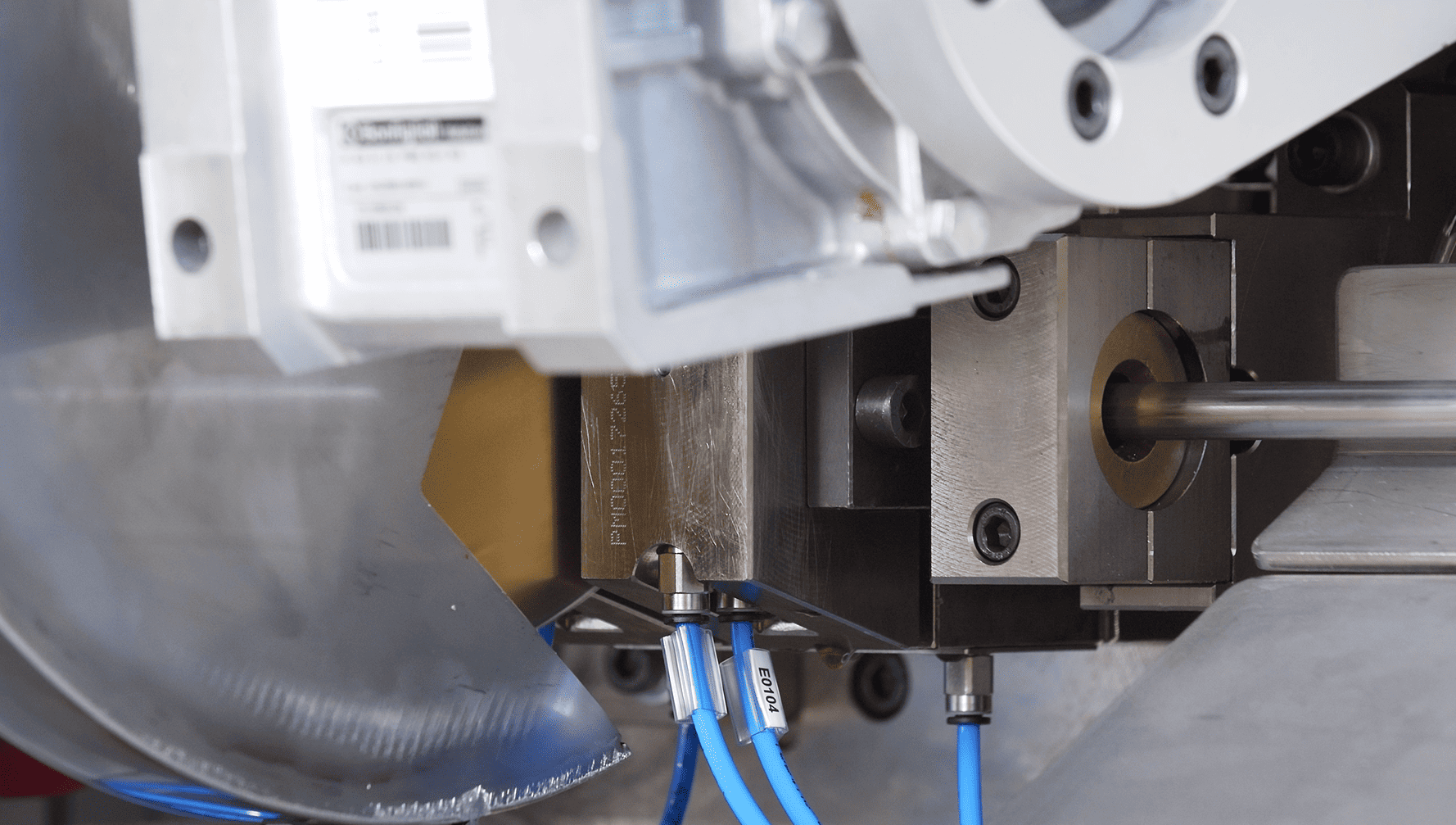

ON-THE-FLY CUTTING SYSTEM

In this device, the cutting unit is integrated in a mobile carriage with controlled axis.

The score and pull-apart system is designed to overcome the problems presented with orbital cutting of a similar conception but realized using engraving wheels. In particular, this system allows the tube to be cut without deformations on the cut edge. The tube is not cut by blades that insist orthogonally on the wall of the tube, but by the combined action of a scoring tooth (made with a three-edged tool), which progressively removes material along a circular section of the cylindrical wall, thinning it, and a clamp that detaches the tube segment.

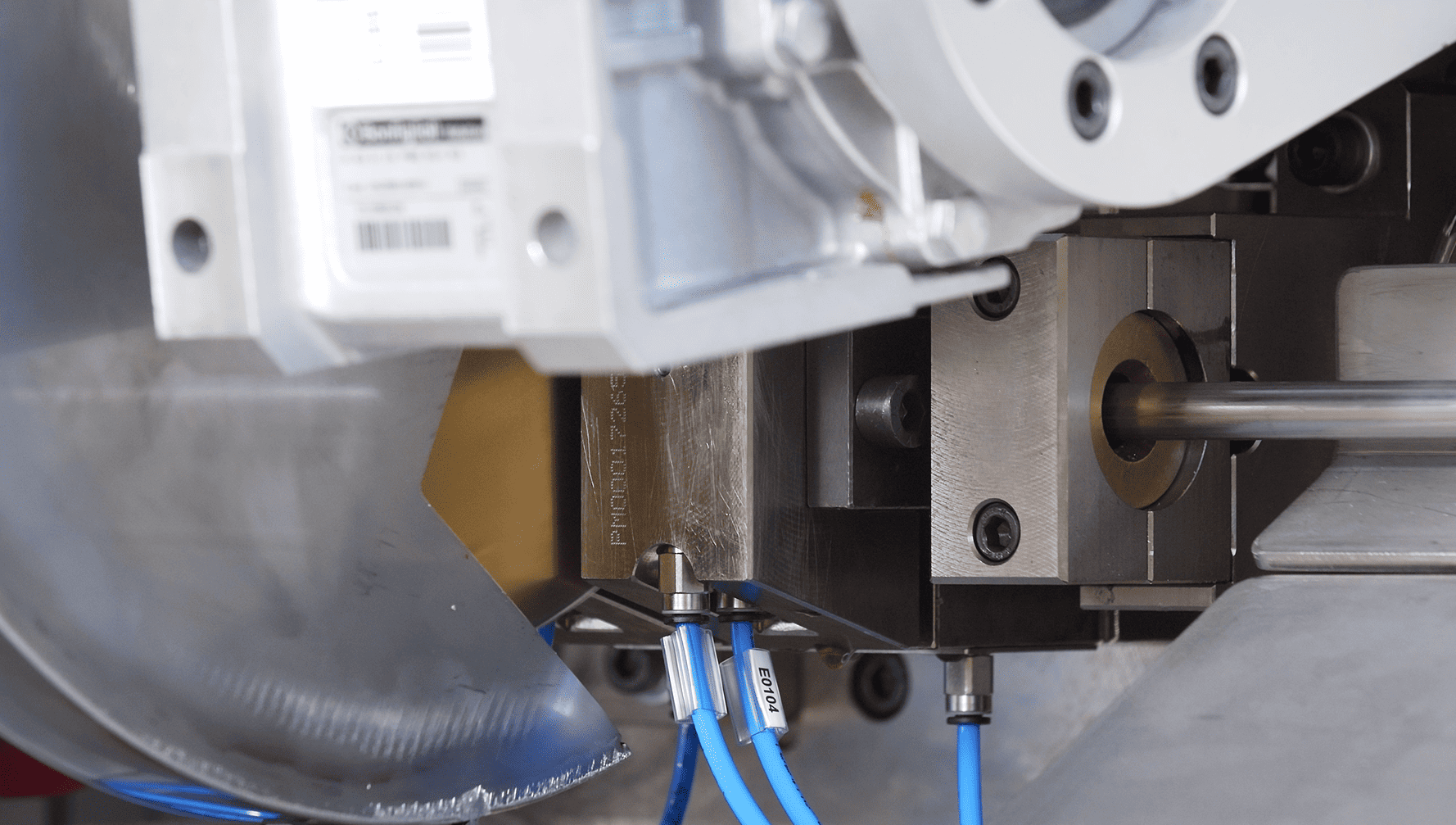

The saw cutting system incorporates a high-resistance circular blade that rotates at high speed to perform rapid and clean cuts. This technology offers the capabilities to manage different types of tube thickness, as well as different materials, with the precision of ninety-degree cuts. Furthermore, thanks to the robust materials and the cutting technique, the tool’s lifespan is extended, ensuring sustained durability and reliability.

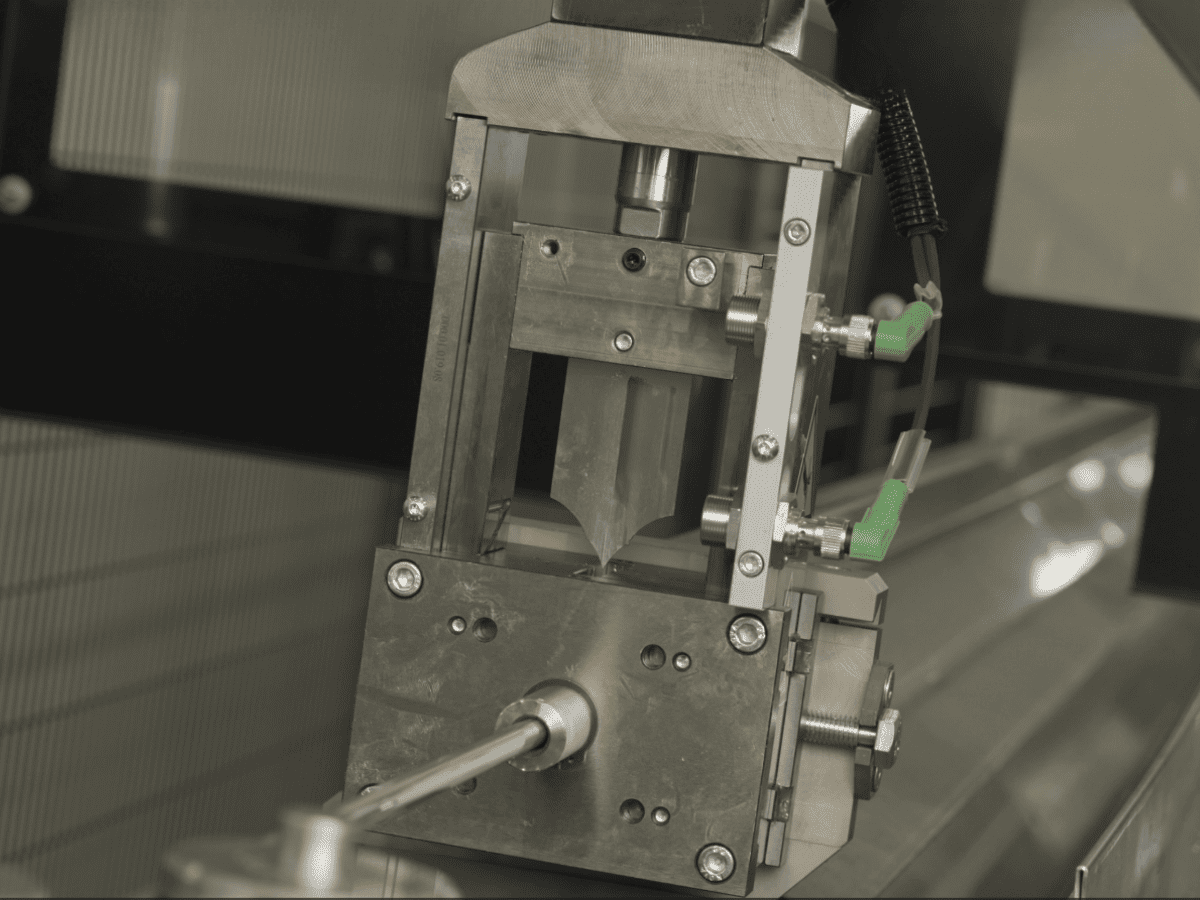

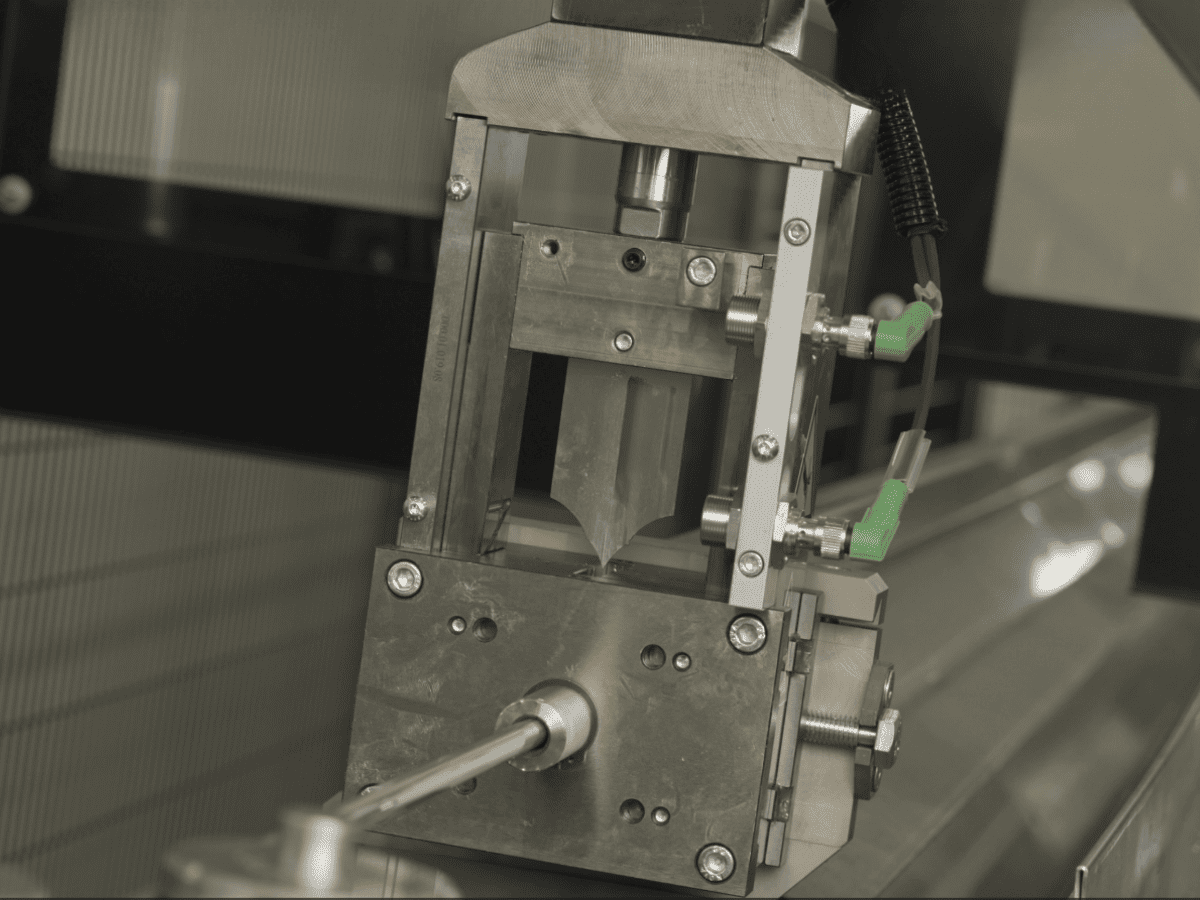

Guillotine cutting lines are designed for producing custom-sized tubes with the internal diameter calibrated at both ends and customized lengths. This type of system is primarily selected for medium to large-scale production, ensuring rapid cutting diameter changeovers. The subsequent punching operation, used to eliminate the “heart-shaped” distortion caused by the cut, can be performed manually via a punching gun or automatically with a punching transfer system downstream of the tube cutting.

The score and pull-apart system is designed to overcome the problems presented with orbital cutting of a similar conception but realized using engraving wheels. In particular, this system allows the tube to be cut without deformations on the cut edge. The tube is not cut by blades that insist orthogonally on the wall of the tube, but by the combined action of a scoring tooth (made with a three-edged tool), which progressively removes material along a circular section of the cylindrical wall, thinning it, and a clamp that detaches the tube segment.

The saw cutting system incorporates a high-resistance circular blade that rotates at high speed to perform rapid and clean cuts. This technology offers the capabilities to manage different types of tube thickness, as well as different materials, with the precision of ninety-degree cuts. Furthermore, thanks to the robust materials and the cutting technique, the tool’s lifespan is extended, ensuring sustained durability and reliability.

Guillotine cutting lines are designed for producing custom-sized tubes with the internal diameter calibrated at both ends and customized lengths. This type of system is primarily selected for medium to large-scale production, ensuring rapid cutting diameter changeovers. The subsequent punching operation, used to eliminate the “heart-shaped” distortion caused by the cut, can be performed manually via a punching gun or automatically with a punching transfer system downstream of the tube cutting.

Tube Materials | Stainless steel, copper, steel, aluminum |

Tube Diameter | mm between 6 and 25 |

Wall Thickness | mm between 0.4 and 1.2 |

Max Tube Length | mm to be defined |

Minimum Length | mm 50 |

Max Line Speed | m/min from 0.5 to 25 |

Max Saw Cutting Speed | cuts/min 12 |

Length Tolerance | mm/m ±0.2 |

Straightness (Bow) | mm/m 1.5–3 |

Tube Center Height from Floor | mm 1,100 |

Electrical Supply | V/Hz 3x400V 50Hz |

Installed Power | KVA 4 |

Pneumatic Supply | Bar 6 |

Machine Color (standard) | Ral 5012 |

Discover the other products in our range