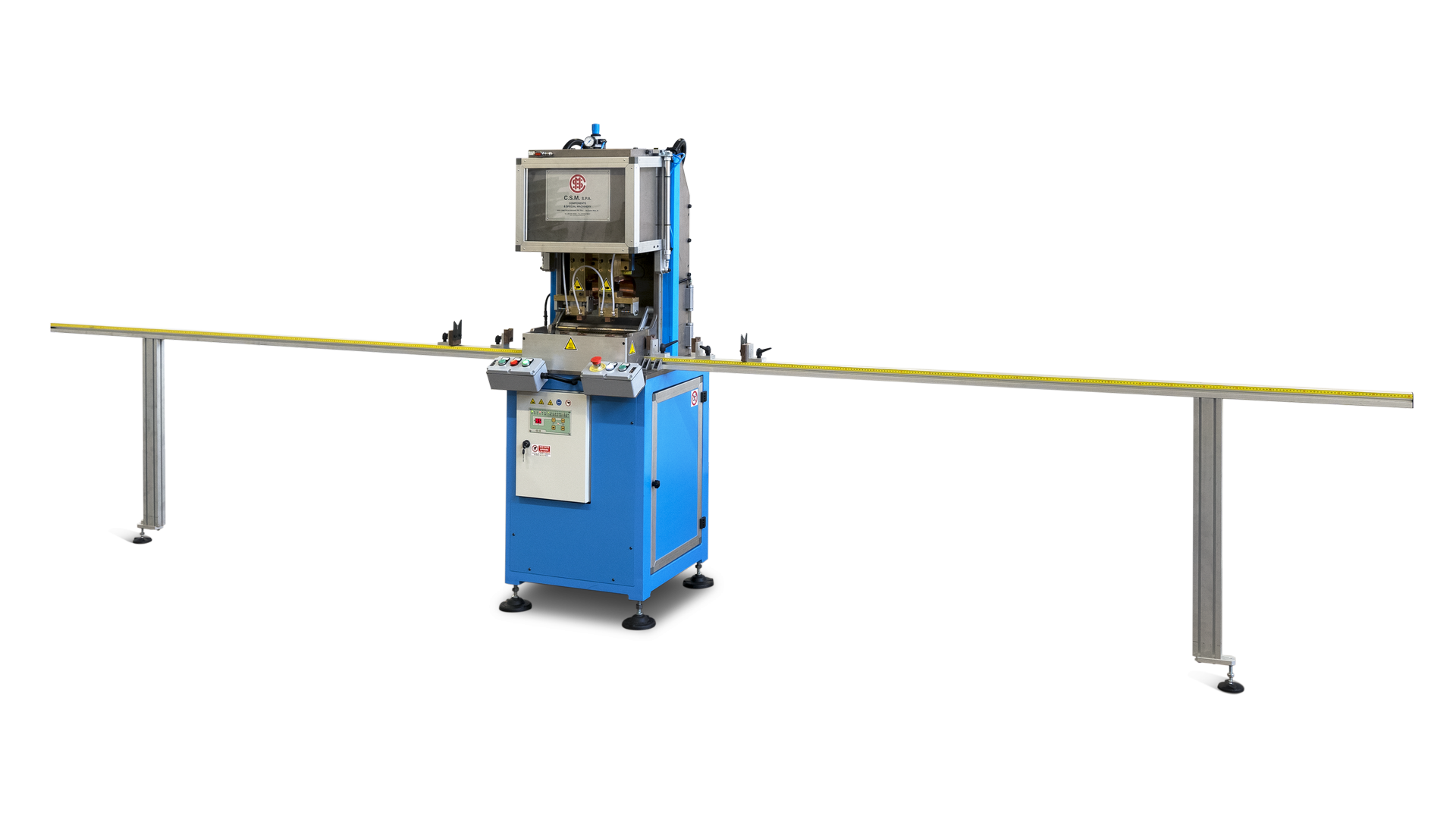

CSM MACHINERY’s annealing system is the ideal solution for the heat treatment of heating elements. The intuitive process involves manual loading and the delivery of low-voltage current via electrodes connected to a transformer.

Clamping electrodes facilitate quick diameter changes, while the manual movement of the component allows for processing heating elements of varying lengths.

Although it does not remove residual moisture from the elements, which requires a de-hydration or moisture removal cycle, the electrical annealing machines from CSM represent an optimal low cost solution for small-scale production.

The concrete advantages that make the difference

using the sensor system during annealing.

when the appropriate temperature is reached.

due to the simple set-up system (clamping electrodes).

Discover all the machine details

TWO PNEUMATIC CYLINDERS DRIVING THE ELECTRODE HOLDERS are mounted on a slide to allow variation of the distance between the axes from 80 to 140 mm.

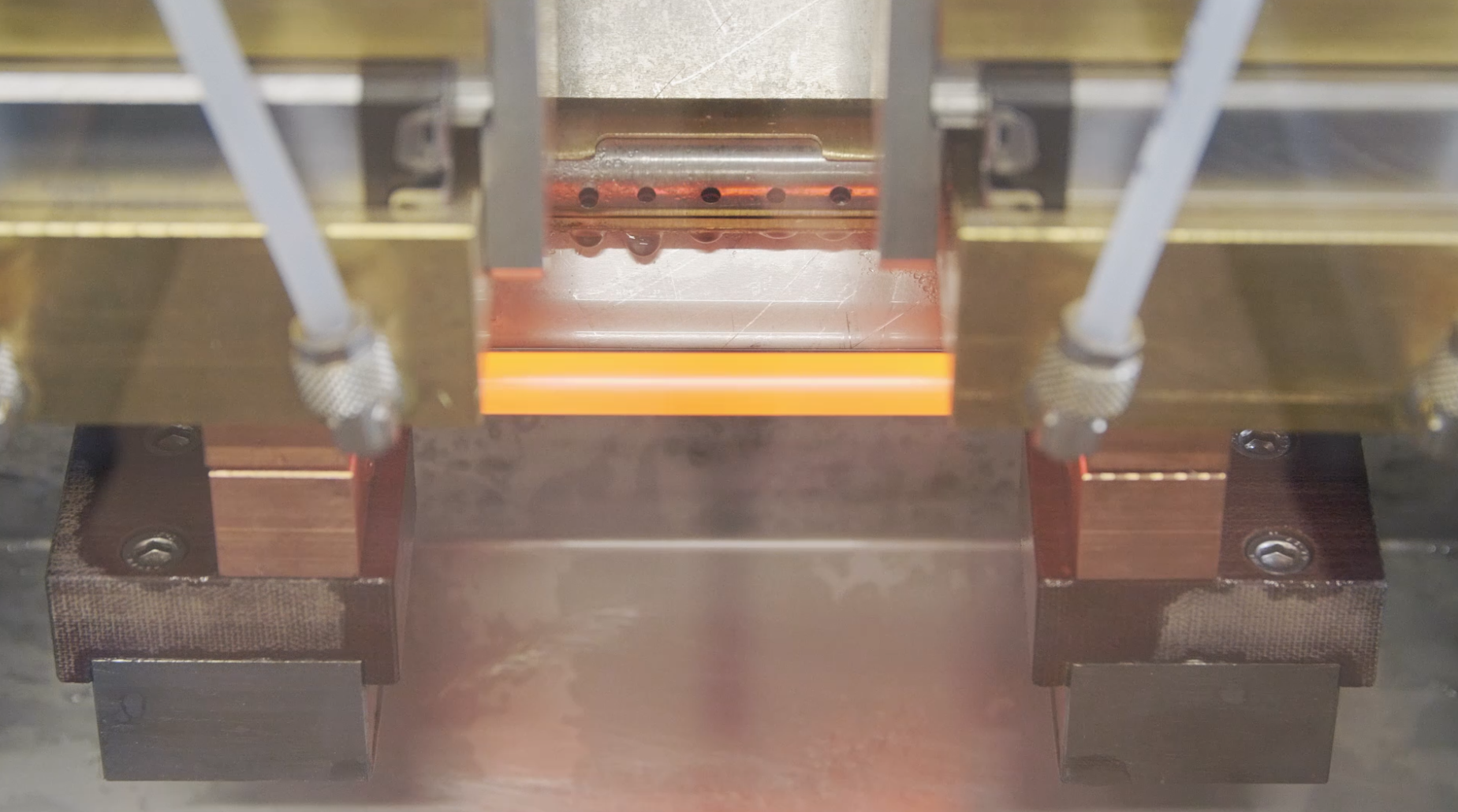

TWO ELECTRODE HOLDERS DESIGNED FOR COOLING THE RESISTORS BY WATER SPRAYING

connected to the transformer by low-impedance cables of suitable cross-section and also designed for water circulation cooling.

ELECTRICAL CABINET COMPLETE OF:

controls to set the closing of the electrodes.

Controls to set the time in periods (Hz) and the percentage of current used for the heat treatment.

Prometer with temperature sensor and control and visualization unit. This system for the control of the temperature is not affected by variations in tube materials or tube wall thickness. The preset temperature can be changed quickly using the operator interface, and the machine allows the operator to program the preset temperature in Celsius or Fahrenheit.

HEAVY-DUTY STEEL FRAMEWORK AND SHEET METAL CONSTRUCTION WITH MACHINE-FINISHED SURFACES

DEVICE TO COOL THE HEATING ELEMENT

by water jets when the flow of current cycle is over. The water used to cool the elements is the same used for cooling the cables and transformers. After being sprayed on the element (to cool it) the water is collected and drained out.

COUNTER ELECTRODE IN COPPER FIXED TO THE FRAME

A 45 KVA TRANSFORMER

The transformer is made of first quality, insulated and magnetic steel sheet, completely impregnated in epoxy resins and it is water cooled.

The CSM spot annealing machine is designed to perform the heat treatment of a section of the heating element after it has been reduced.

Installed power | 45 KVA |

Power supply (three-phase) | V/Hz to be defined |

Pneumatic supply | 6 Bar |

Air consumption | 1,5 l/cycle |

Water supply for cooling | 2 Bar |

Water consumption | 2-3 l/min. |

Section of the element to be annealed | from 80 to 140 mm |

Tube diameter | mm to be defined |

Tube material | Copper-steel-stainless steel |

Expected cycle time | 5 – 6 sec. |

Discover the other products in our range