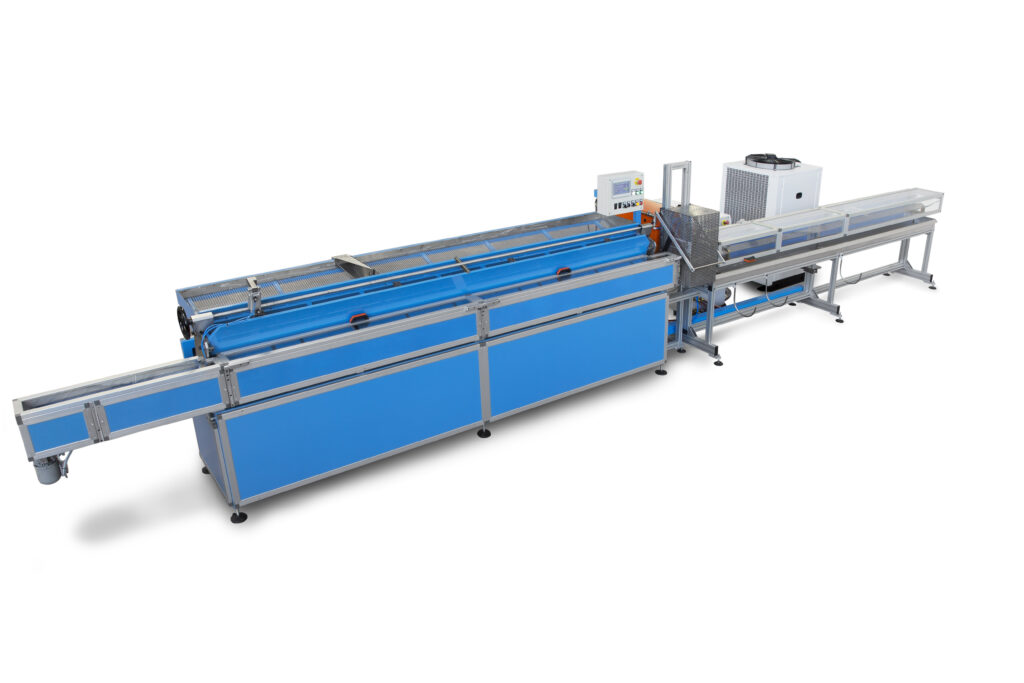

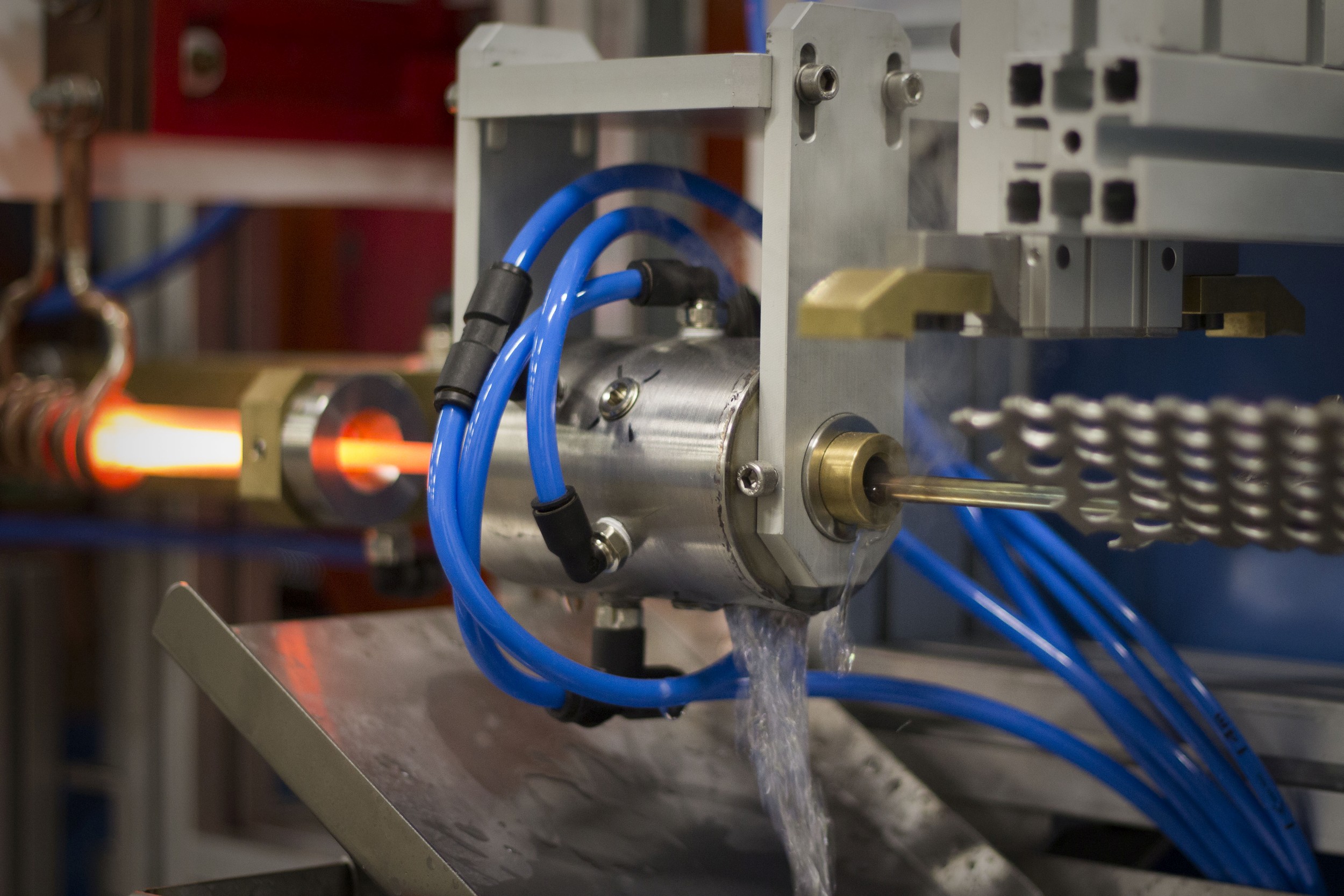

The induction annealing machine is designed to anneal austenitic stainless steels and copper by induction, with manual or automatic feeding. This machine is provided with a cooling chamber that can be filled with inert gas for blanketing when bright annealing is requested.

Operators can select the machine’s operating mode, either spot annealing or total annealing, via the control panel, depending on their specific needs. Due to the rapid nature of the induction annealing process, it does not remove residual moisture from the components, which therefore require a drying treatment beforehand.

The concrete advantages that make the difference

Spot or total annealing with customized CSM MACHINERY solutions.

Power-on only when required, preventing waste through advanced technologies.

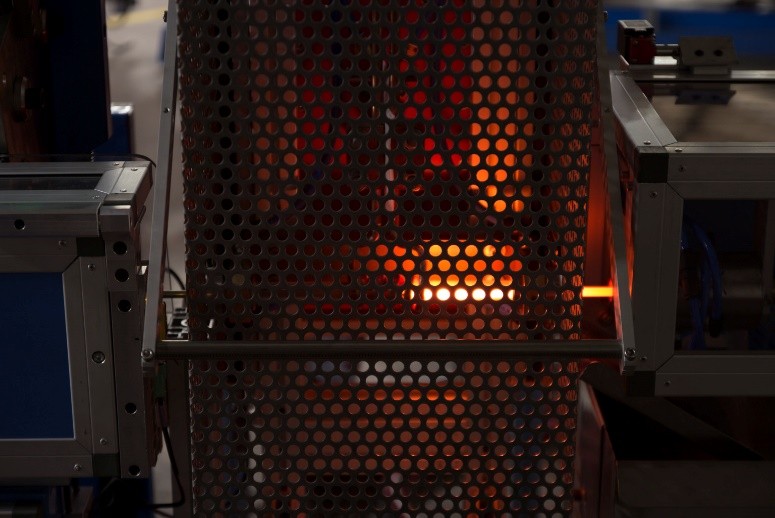

Limits oxidation of elements at high temperatures.

Discover all the machine details

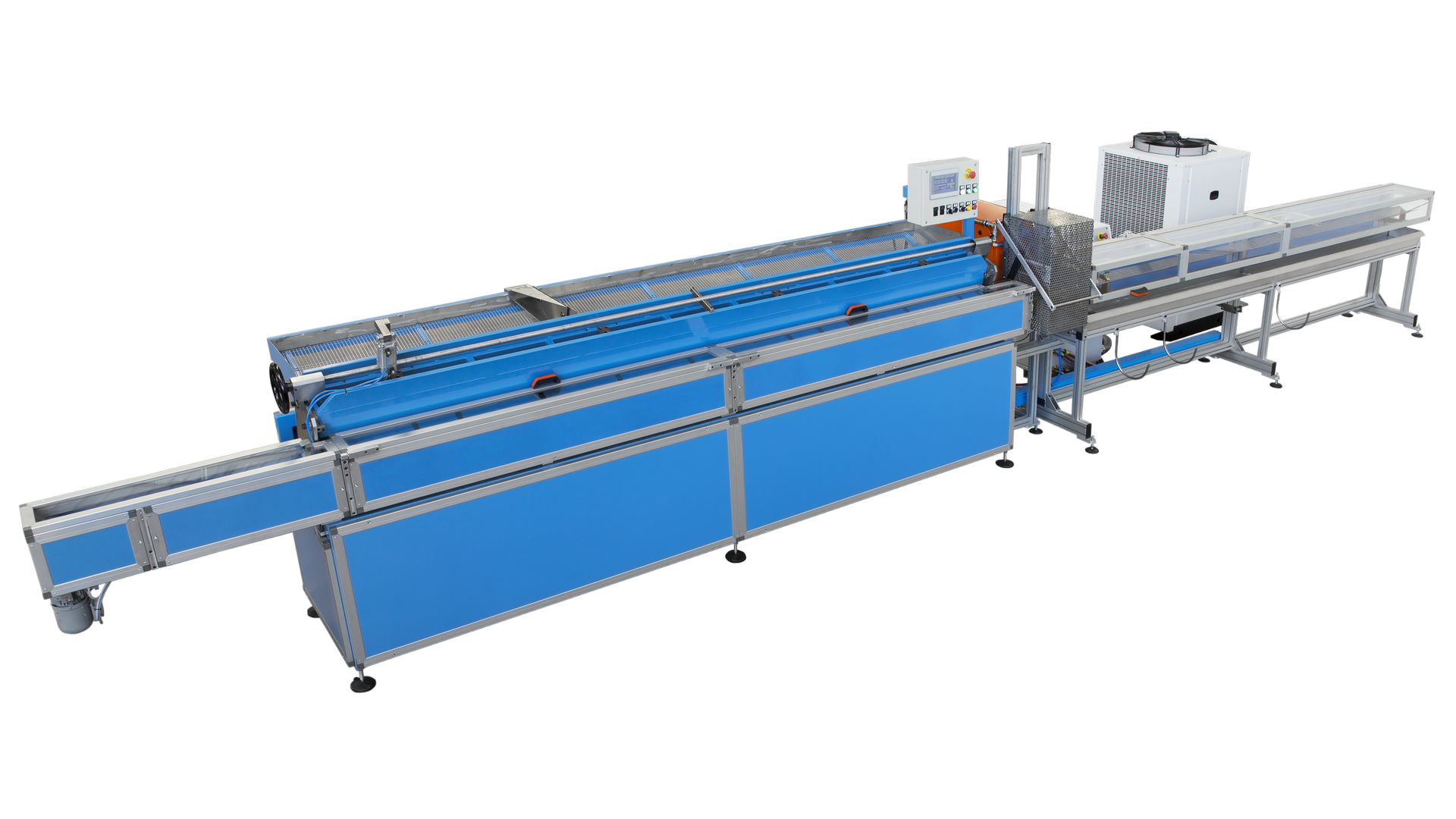

NUMERICAL CONTROL INSERTION SYSTEM

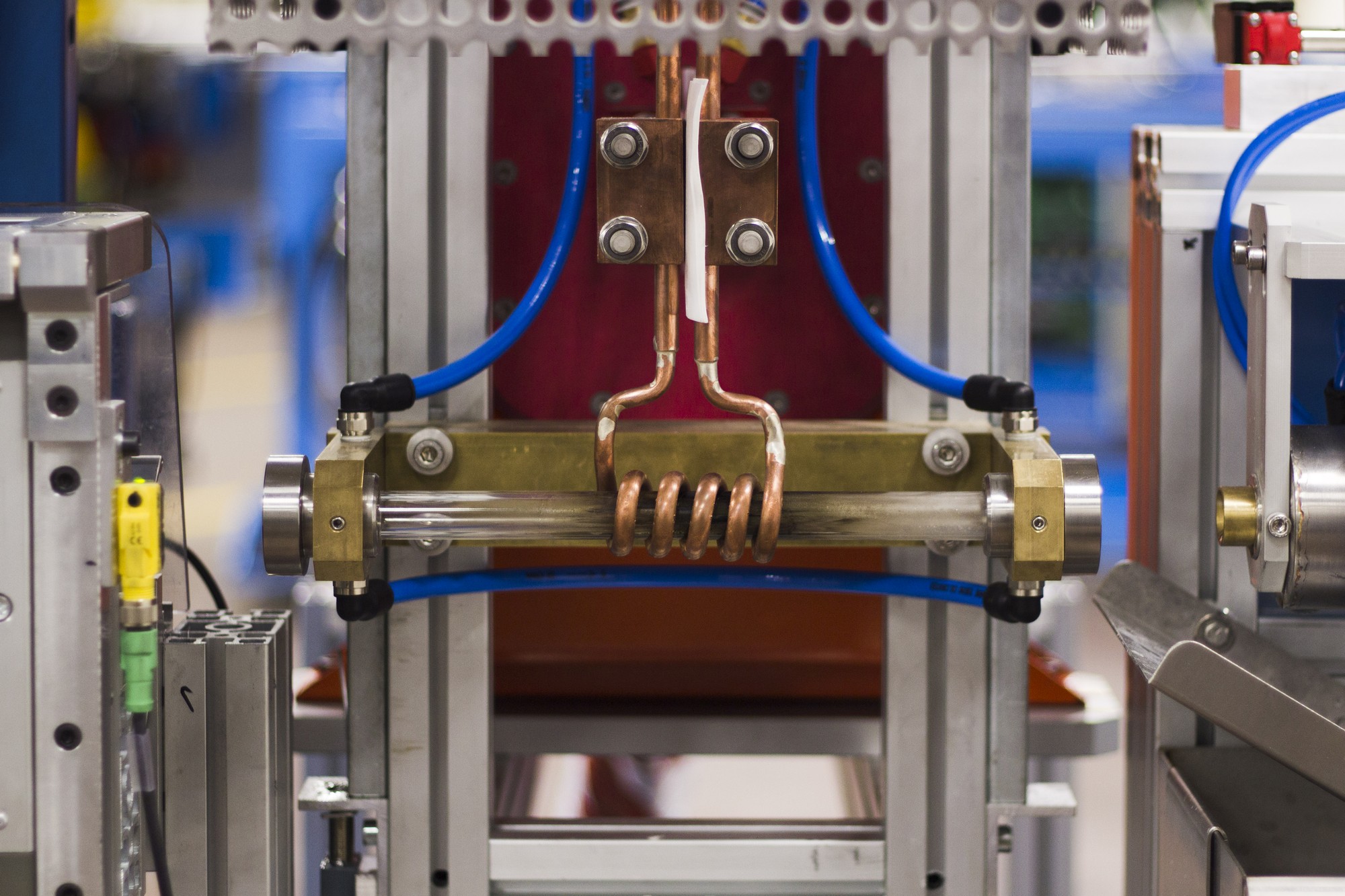

ANNEALING SECTION

INDUCTION GENERATOR

COOLING SYSTEM FOR THE INDUCTION GENERATOR

UNLOADING SECTION

NOTE

The machines are supplied complete for one diameter of element. To process additional diameters may require additional tooling. The standard application is austenitic stainless steel. Copper can be used but a compromise must be reached for both materials and this means that some efficiency will be lost for the stainless steel. If the two materials are to be processed, this should be specified when placing the order.

Material | 300-series stainless steels |

Heating element diameter | 6-16 mm |

Heating element length | 300-6000 mm |

Operating mode | Complete and spot |

Number of spots in spot mode | no. 12 |

Installed power | |

Power supply | 3 x 400 V; 50 Hz |

Compressed air | 6 Bar |

Once-through water | 2-4 l/min |

Generatore | 30 o 50 o 75 KW |

Speed | adjustable from 0.5 to 10 m/min |

Discover the other products in our range