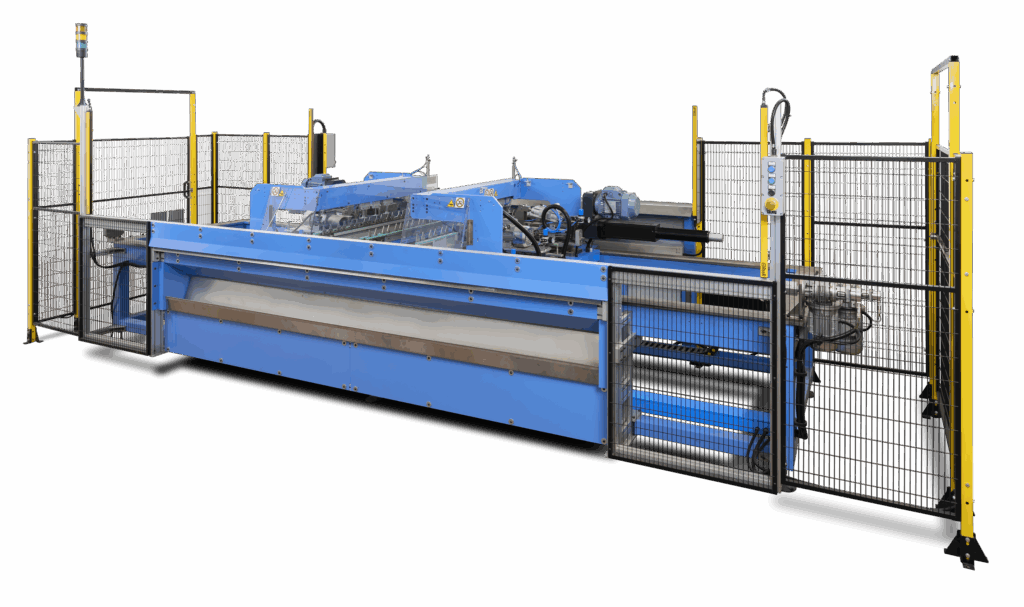

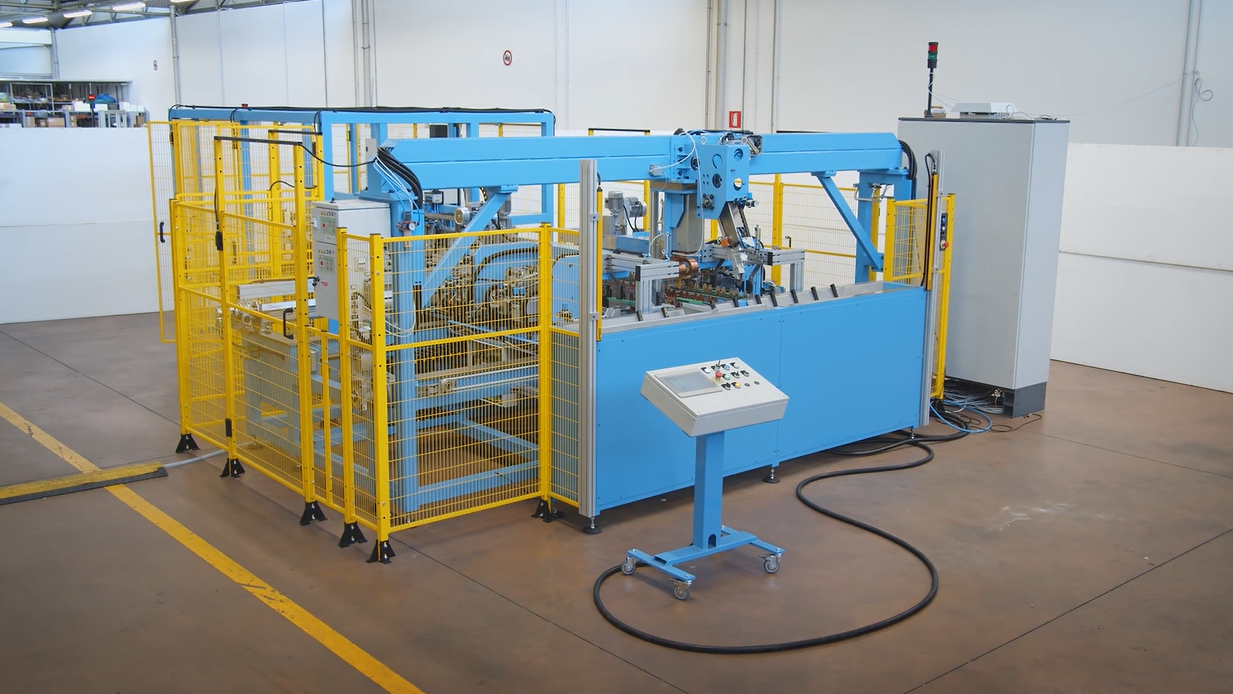

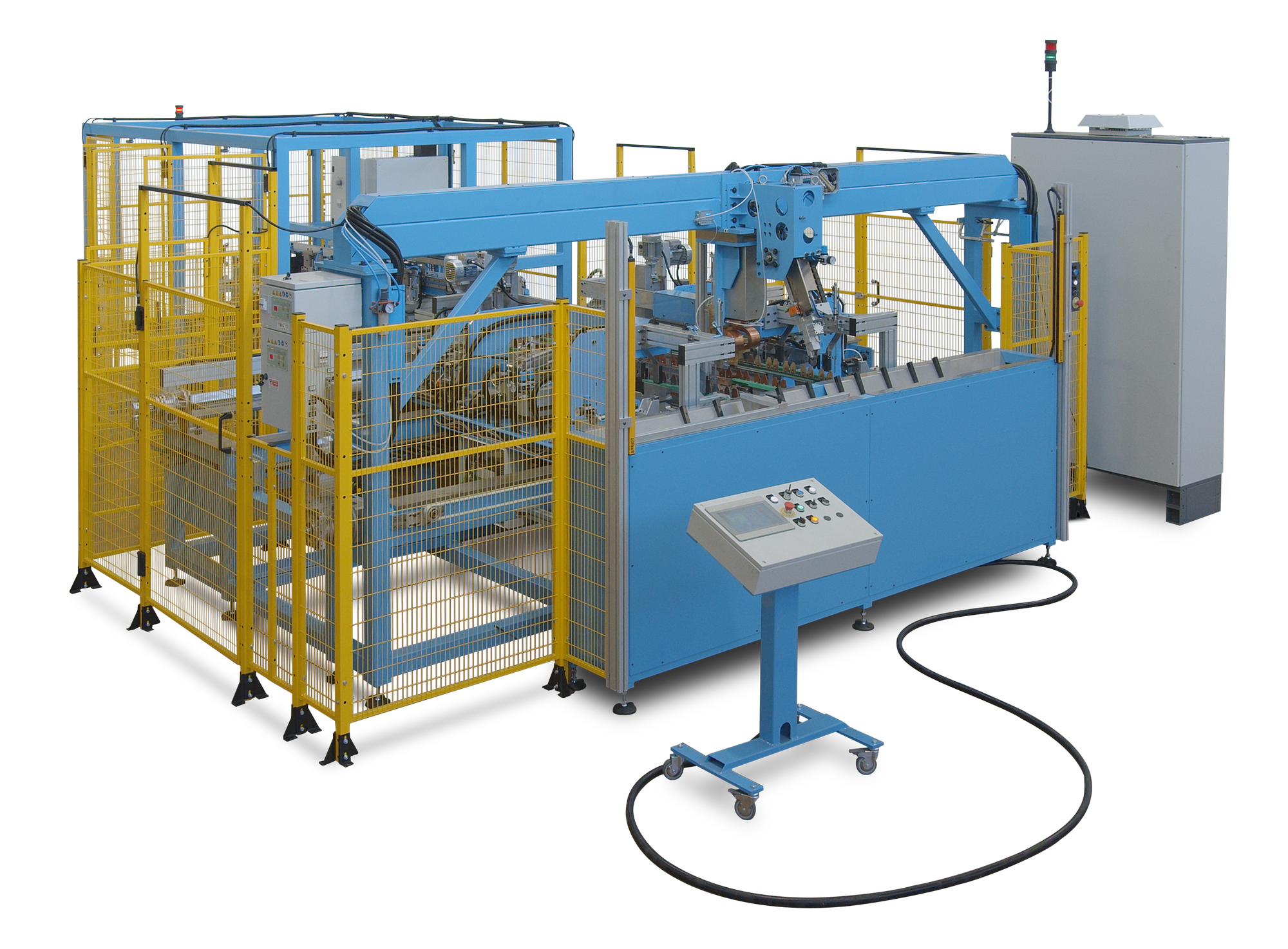

CSM MACHINERY’s multi-operation transfer machines are automation solutions that combine several functions, typically performed by separate machines, into a single unit. These multi-operation transfers offer versatile production capabilities, allowing them to incorporate various types of working units to meet specific customer requirements.

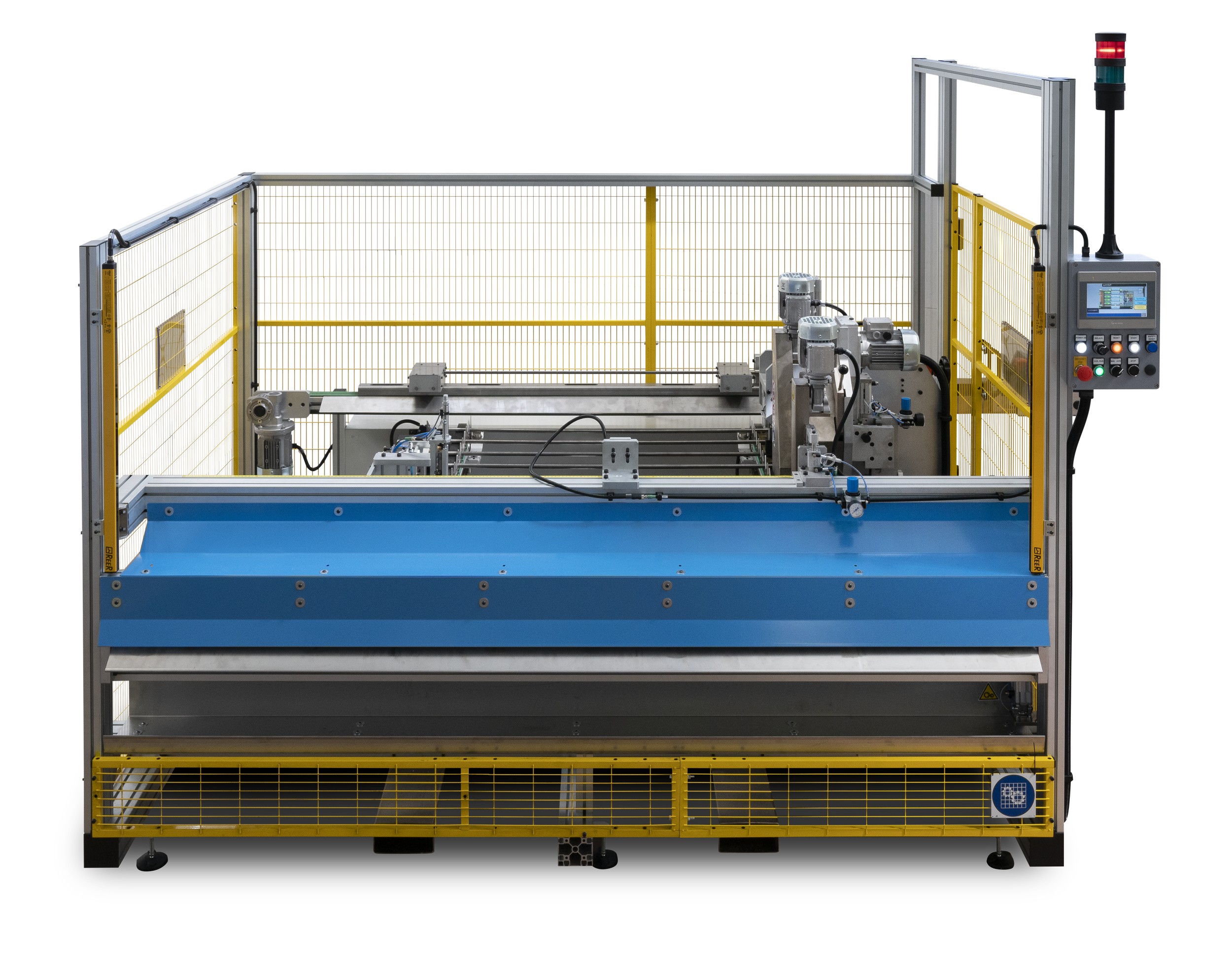

These machines consist of a series of stations that transport and process parts autonomously and without interruption. They are equipped with sensors and monitoring systems that provide operators with real-time feedback, ensuring precise control over each operation and guaranteeing quality.

The concrete advantages that make the difference

within the production plant and more effective space management.

due to the combination of various operations in a single machine.

achieved with automation systems integrated into the production lines.

The transfer for the preparation of heating elements after heat-treatment consists of five workstations:

The multi-operation transfer allows to process heating elements with different lengths by simply changing the machine settings.

This machine consists of the following units:

This type of transfer is positioned in line with the rolling mill to directly collect the cartridge heaters that are exiting.

This multi-operation transfer consists of five workstations:

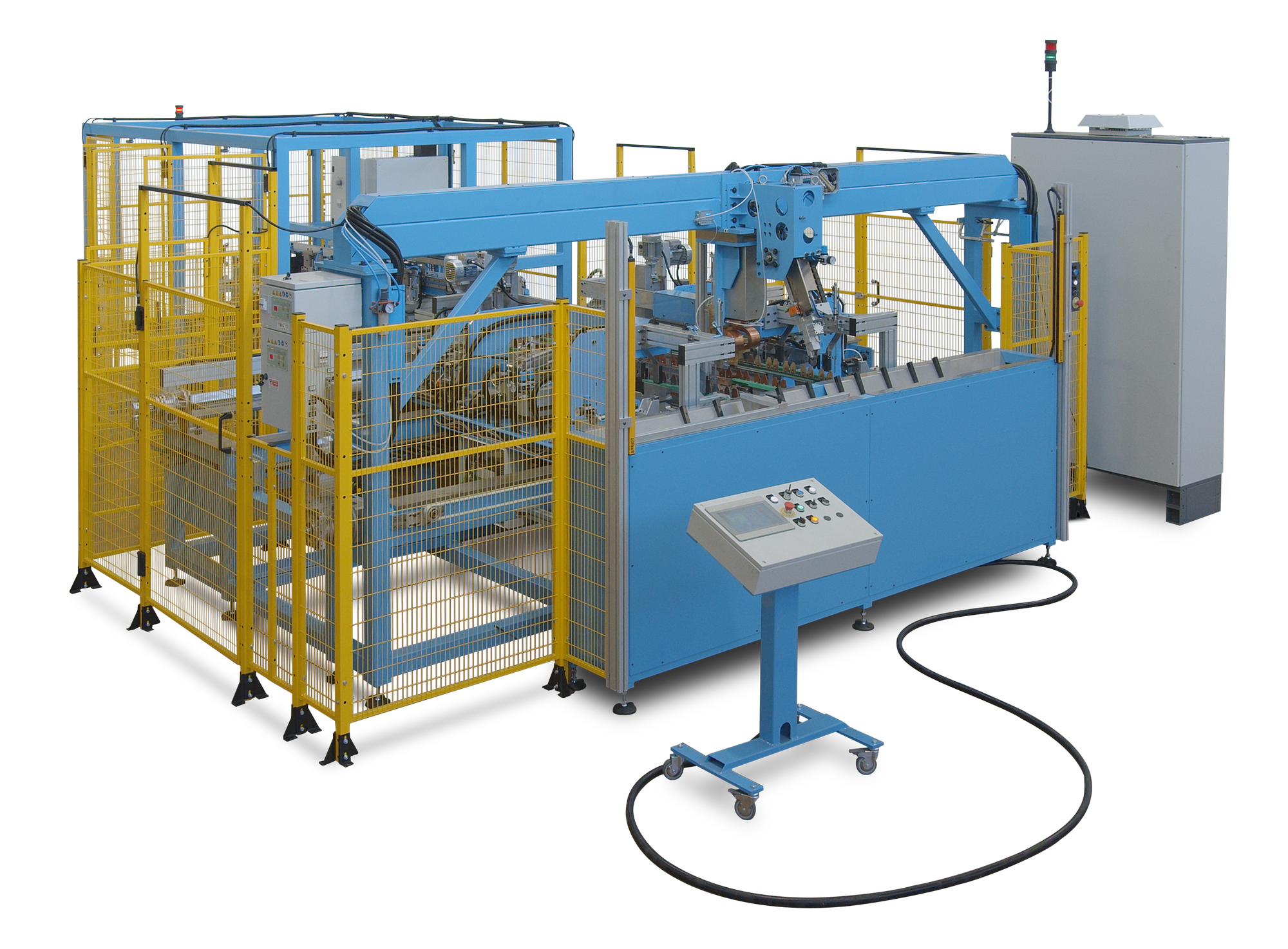

This is the most complex type of transfer as it consists of two work sections in which different operations are combined.

The first section consists of:

Subsequently, in the second section of the transfer, we find:

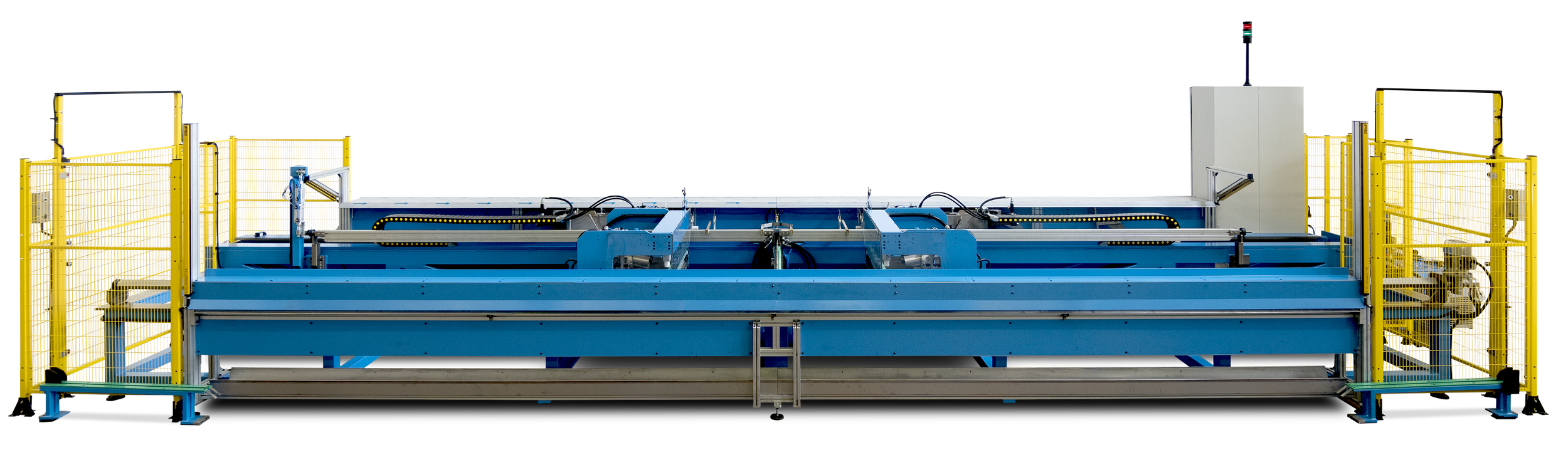

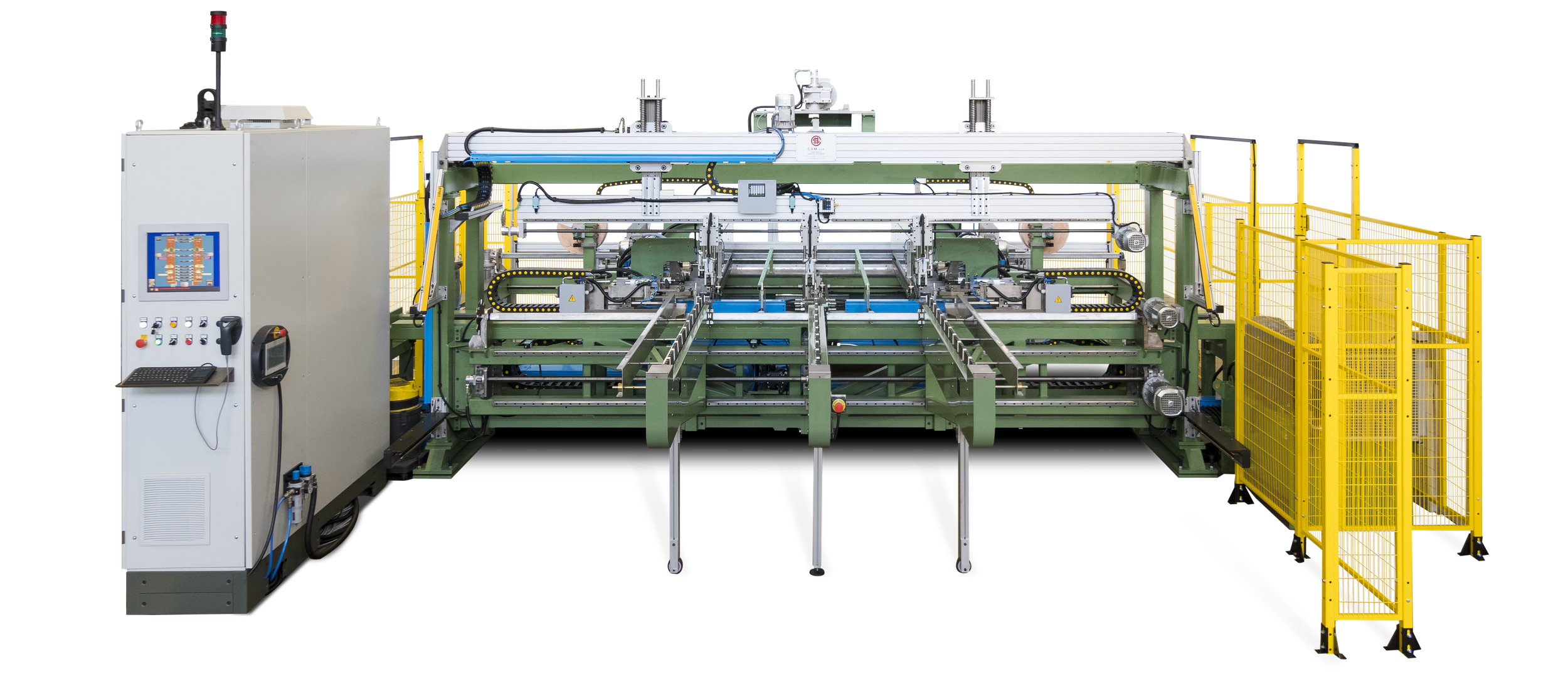

The multi-operation transfer for the stretching and sealing of heating elements consists of ten workstations:

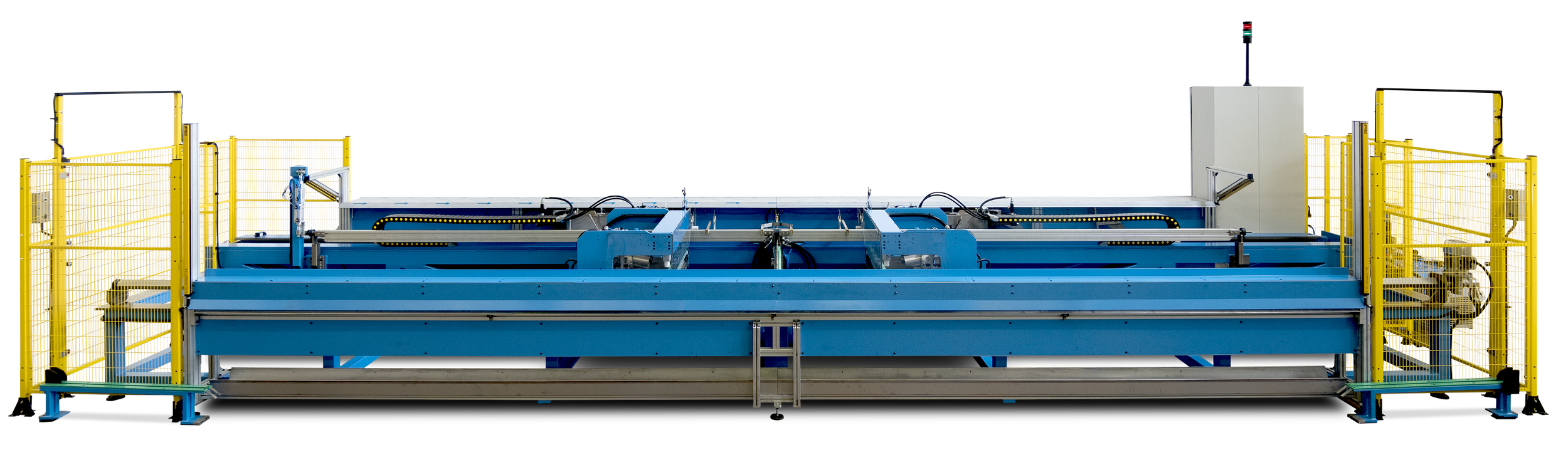

This type of transfer is positioned in line with the reduction mill in order to collect the heating elements that are exiting.

This device consists of three workstations:

At the end of the cycle, the transfer automatically unloads the heating elements into a container at the foot of the machine and selects any scraps.

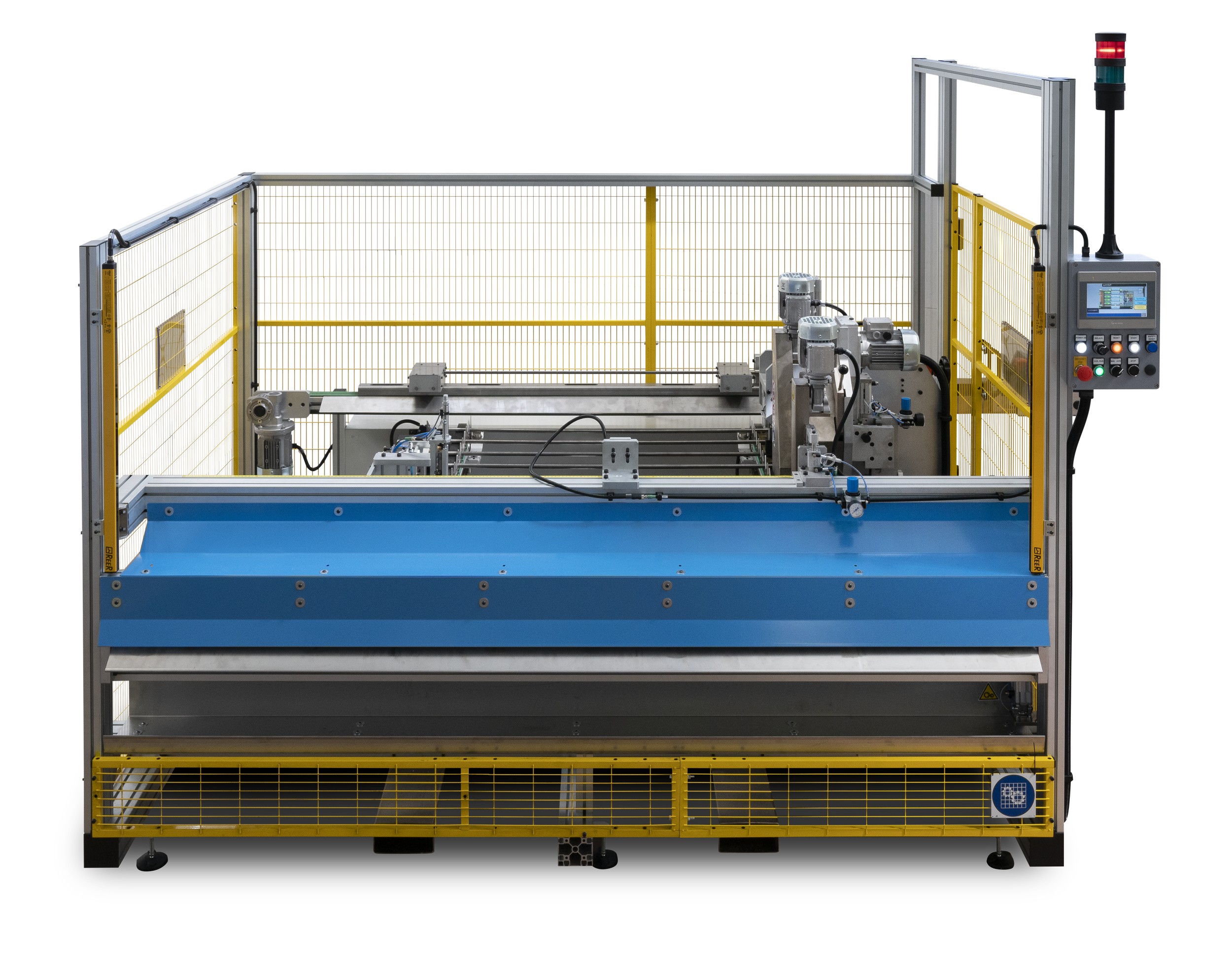

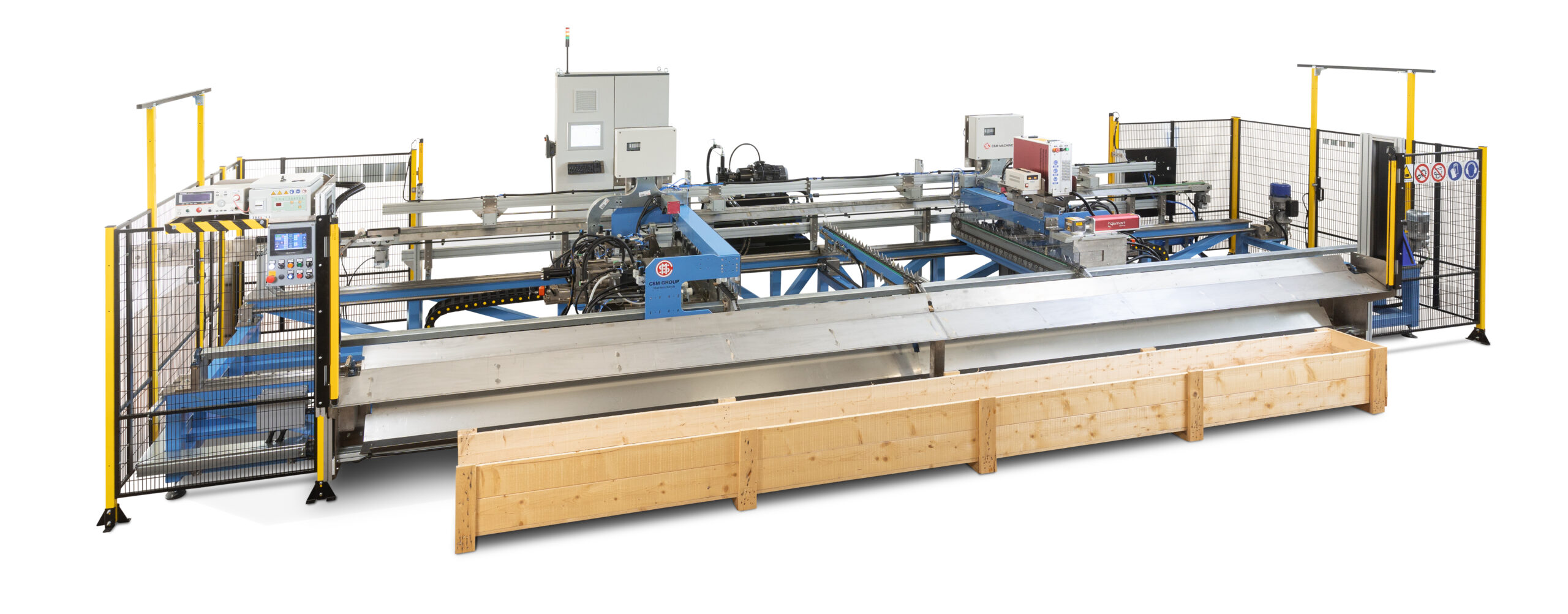

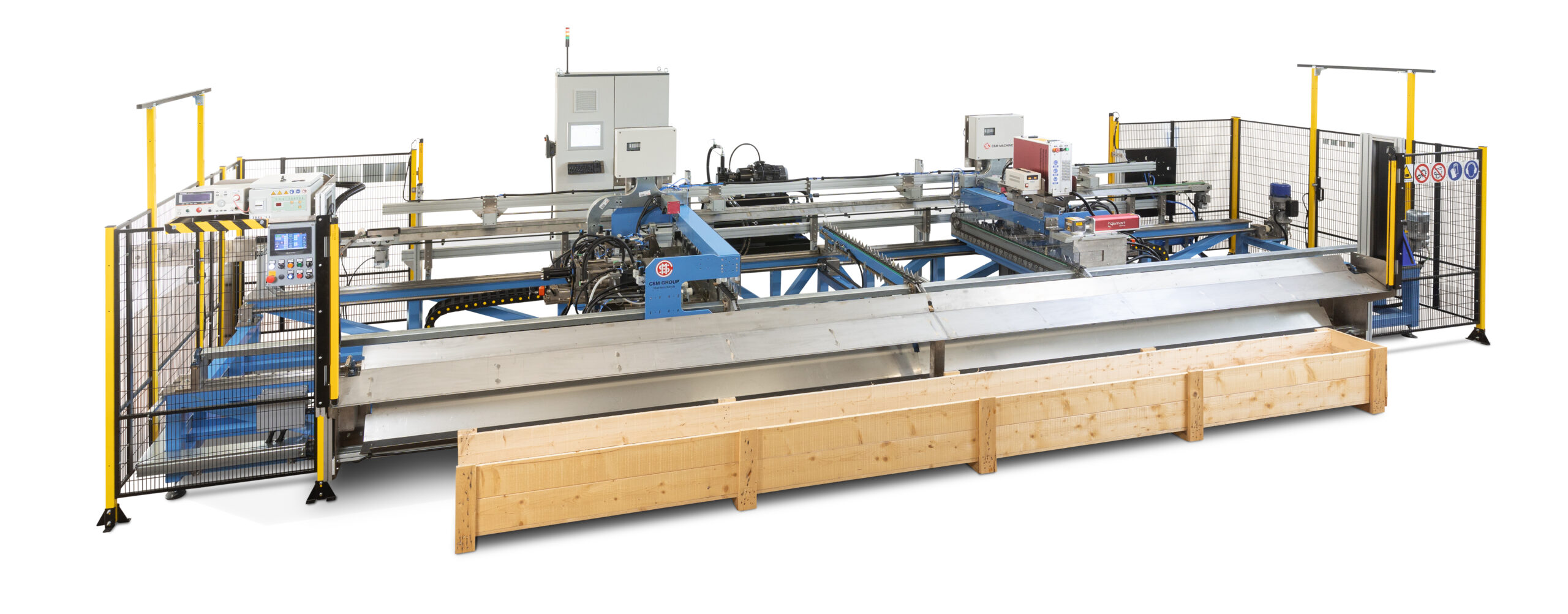

The automatic machine to process defrost heating elements’ ends is conceived to collect the element at the exit of the rolling mill and can process elements up to 7000 mm length.

The machine consists of seve working units:

The transfer for the preparation of heating elements after heat-treatment consists of five workstations:

The multi-operation transfer allows to process heating elements with different lengths by simply changing the machine settings.

This machine consists of the following units:

This type of transfer is positioned in line with the rolling mill to directly collect the cartridge heaters that are exiting.

This multi-operation transfer consists of five workstations:

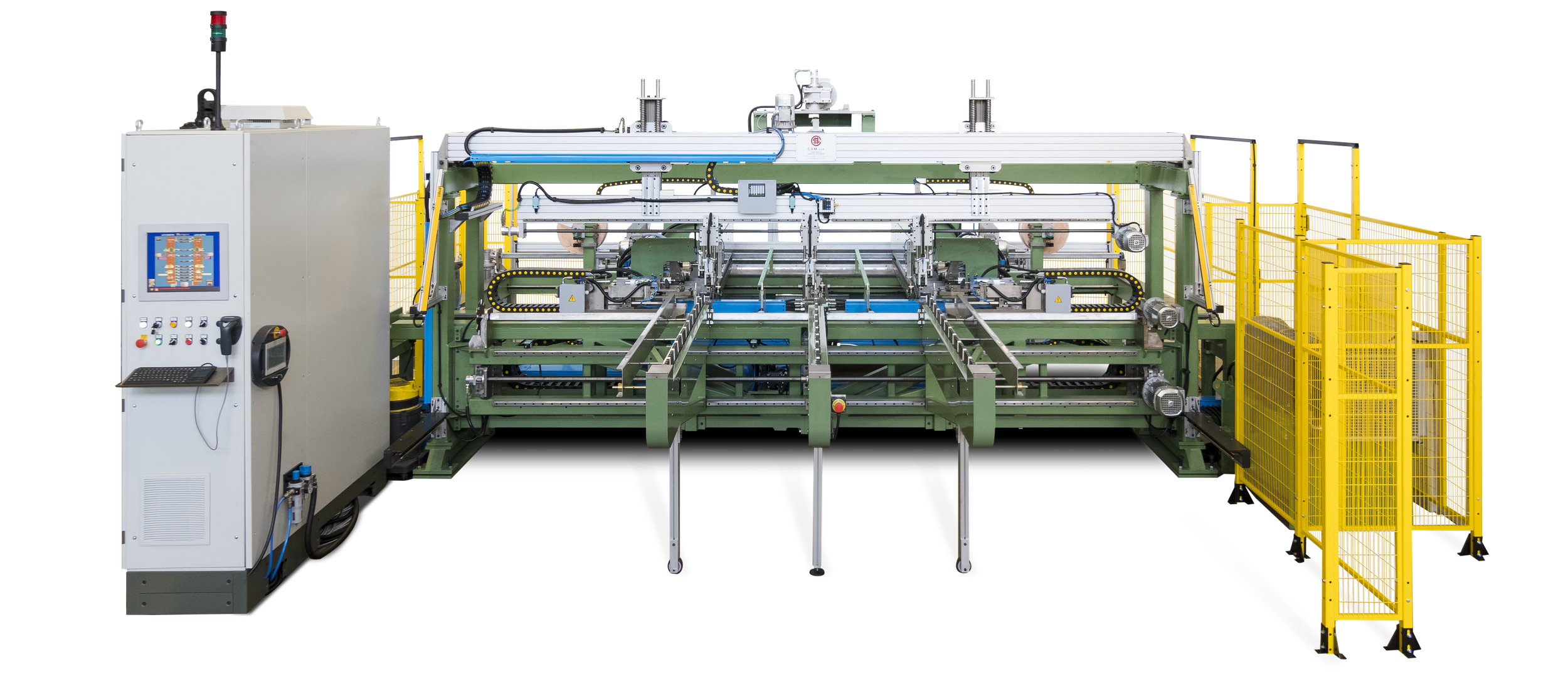

This is the most complex type of transfer as it consists of two work sections in which different operations are combined.

The first section consists of:

Subsequently, in the second section of the transfer, we find:

The multi-operation transfer for the stretching and sealing of heating elements consists of ten workstations:

This type of transfer is positioned in line with the reduction mill in order to collect the heating elements that are exiting.

This device consists of three workstations:

At the end of the cycle, the transfer automatically unloads the heating elements into a container at the foot of the machine and selects any scraps.

The automatic machine to process defrost heating elements’ ends is conceived to collect the element at the exit of the rolling mill and can process elements up to 7000 mm length.

The machine consists of seve working units:

Discover the other products in our range