In the production of heating elements, variations in length can compromise the quality of the final product. To address this challenge, CSM MACHINERY has developed a roll to length machine, an innovative solution designed for seamless integration directly into the production line, positioned downstream from the reduction rolling mill.

This system precisely measures the length of each heating element as it exits the rolling mill and corrects any inconsistencies from a pre-set reference value. The roll-to-length machine achieves this by elongating the heater through a second, controlled diameter reduction. This process can be applied to the entire length of the elements or, selectively, by excluding programmable initial and final sections, offering enhanced flexibility and customization of the manufacturing process.

Thanks to advanced technologies and tailored solutions, the roll-to-length machine contributes to innovation in heating elements production, ensuring superior precision and quality.

The concrete advantages that make the difference

without structural modifications.

across the entire length of the tubular element.

to ensure the dimensional accuracy required in production

Discover all the machine details

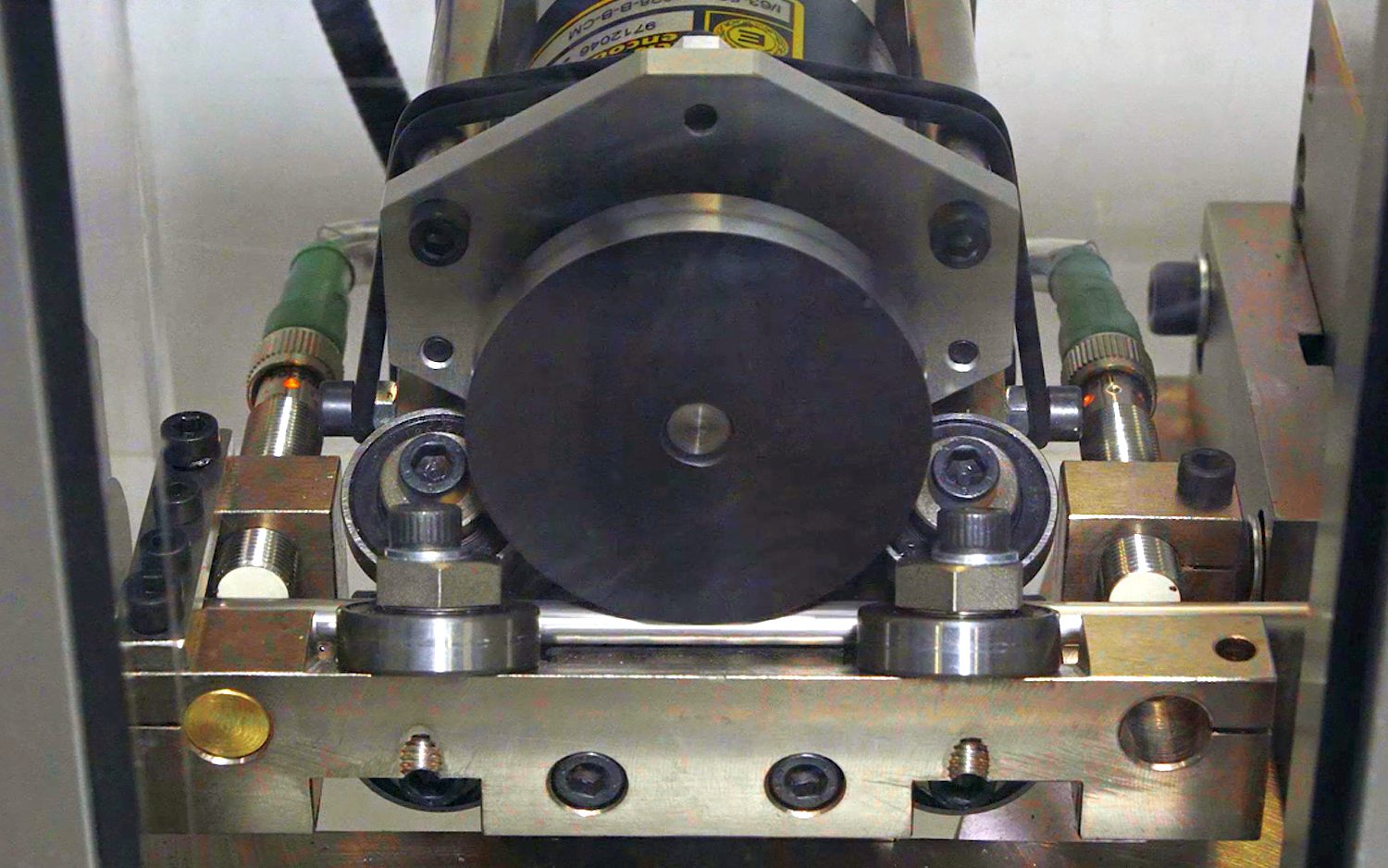

FIRST ELECTRONIC MEASURING DEVICE WITH ENCODER

to measure the tube length at the exit of the roll reducing mill. Automatic calculation and storage of the length difference compared to the set value (Final required length).

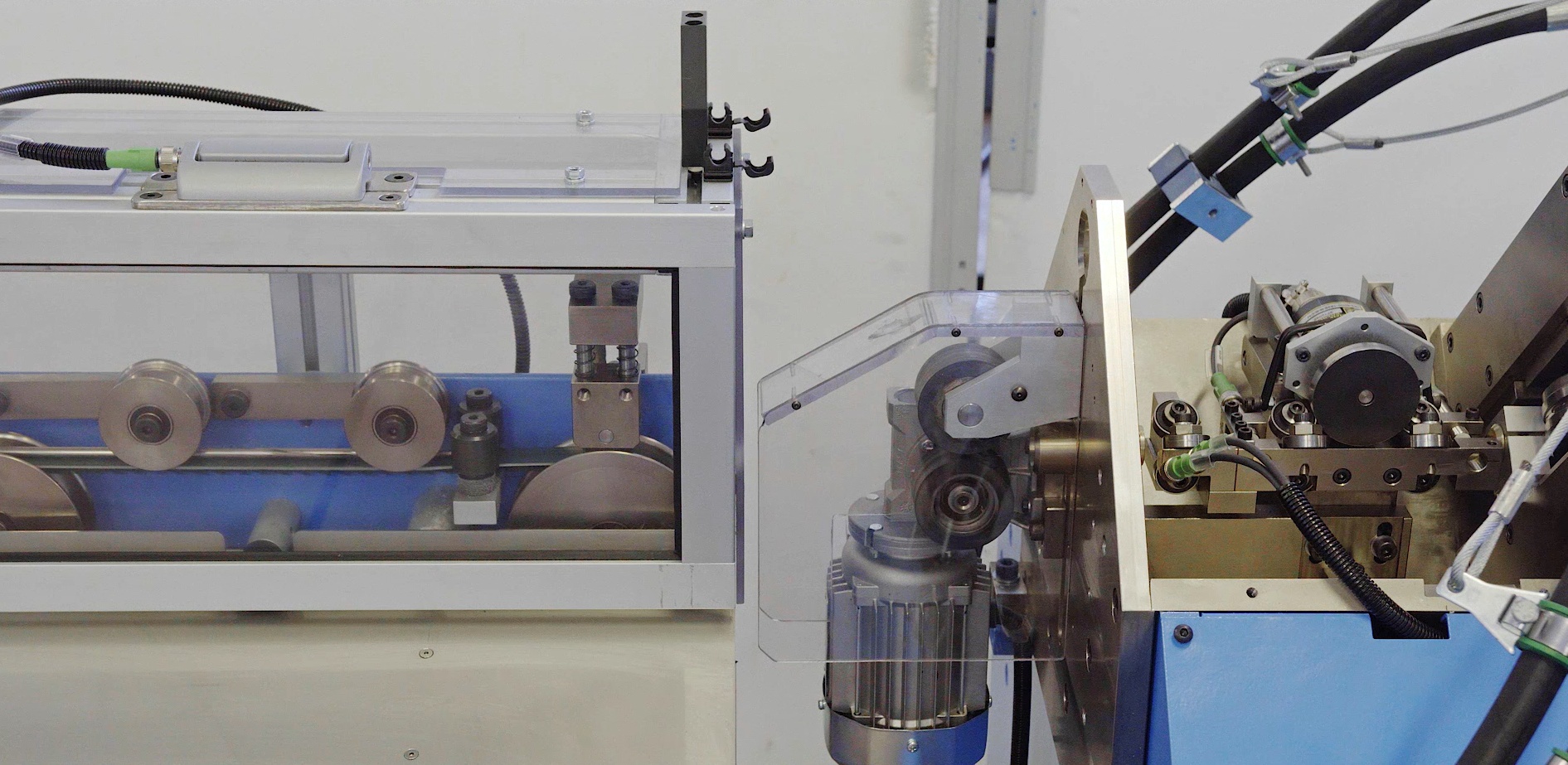

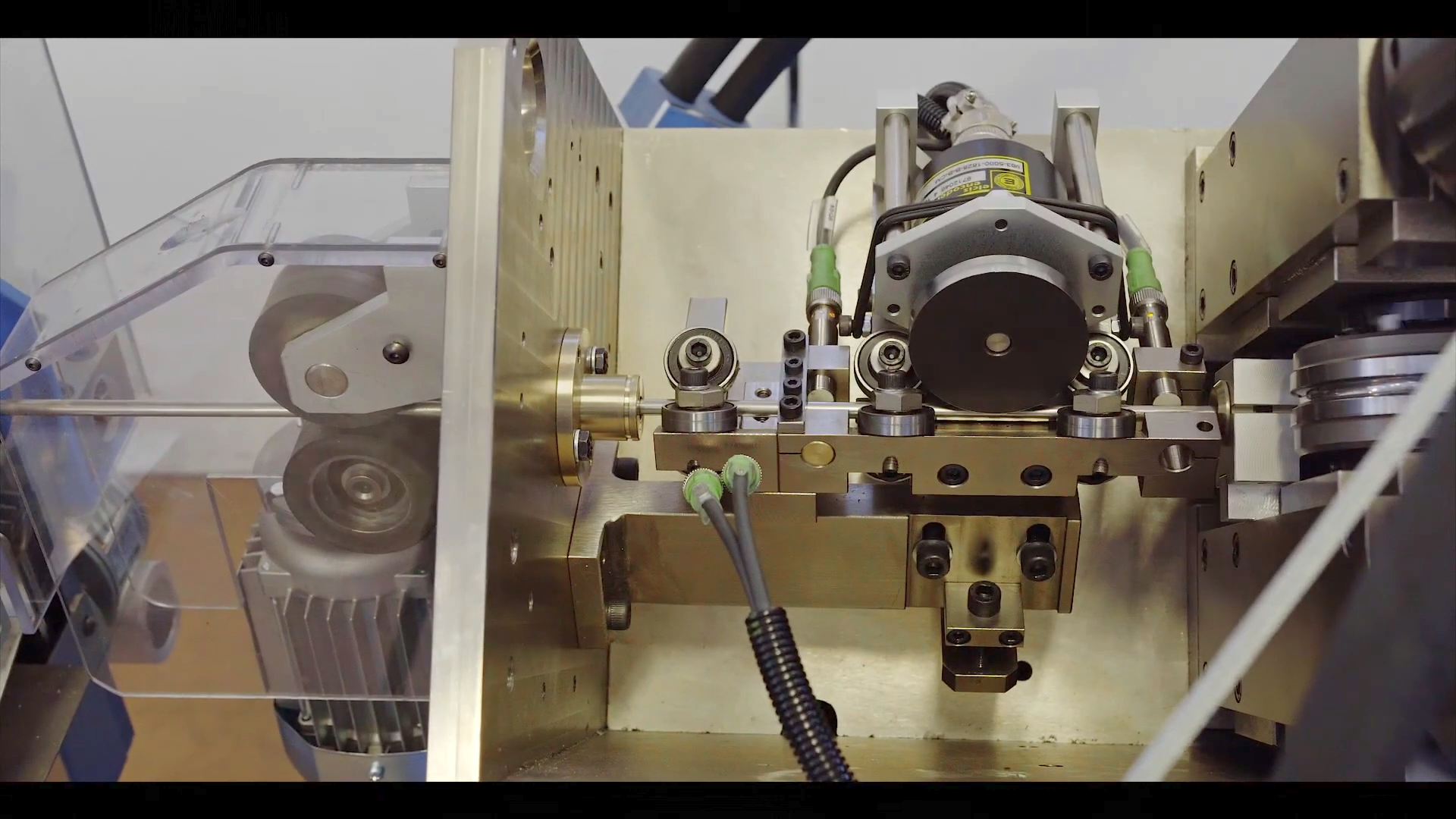

GROUP FOR THE SECOND DIAMETER REDUCTION

formed by 2 pairs of motorised rolls. The upper rolls lower with an hydraulic movement for the 2nd diameter reduction (of 0.1 mm.) for a length elongation which is equal to the difference between the real heating element length (measured by the 1st encoder at the exit of the roll reducing mill), and the final set length.

DEVICE TO TRANSFER

heating elements from the exit of the first measuring station to the machines.

NOTE

The presence of the plastic plugs on both ends of the heating element does not affect the accuracy of tube length measurement, provided that their diameter after the diameter reduction is max. 0.3 – 0.4 mm larger than the heating element diameter. Larger diameters could affect the final tolerance on the heating element.

MAIN ELECTRONIC BOARD

with PC and keyboard.

SECOND ELECTRONIC MEASURING DEVICE WITH ENCODER

to measure the heating element length as it enters the machine for the second diameter reduction.

THIRD ELECTRONIC MEASURING DEVICE WITH ENCODER

to measure the element length after the second diameter reduction and storage of the value to select the heating elements that have not reached the set length.

STRAIGHTENING GROUP WITH NON MOTORIZED ROLLS

UNIT TO REMOVE

heating elements at the end of the cycle.

Minimum heating element length | mm to be defined |

Maximum heating element length | mm to be defined |

Heating element diameter (one diameter to be defined) | 6-12 mm |

Feeding speed | 20 m/min. |

Diameter reduction | 0,1 mm |

Power supply voltage | V to be defined |

Hydraulic pressure | 150 Ate |

Final heating element tolerance | ±1-1,5 mm |

Discover the other products in our range