At CSM MACHINERY, we develop machinery for every stage of the electric heating element production process, ensuring efficiency and high quality. From tube cutting to coil production with coiling machines, through to filling, annealing, and finning, we guarantee an optimised process.

Our expert consultants will help you identify and configure the ideal machine for your production needs.

Our technicians are ready to help you find the best solution for your specific requirements.

To manufacture an electric heating element, we begin by defining the tube length, which will serve as the container for the resistive wire and other components. We offer various tube cutting solutions, designed to suit specific production needs and ensure cutting precision and quality.

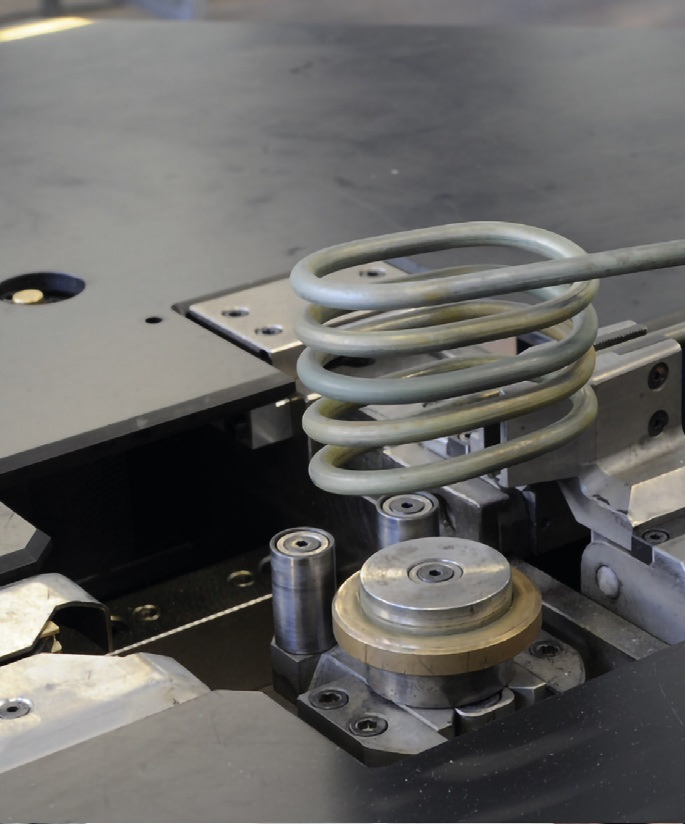

Inside an electric heating element, the coil is made of one or more resistive metal wires, and it is crucial that it is produced with continuous ohmic measurement to ensure the correct resistance value. We use advanced technologies for forming and processing coils, ensuring precision, reliability, and quality control at every step.

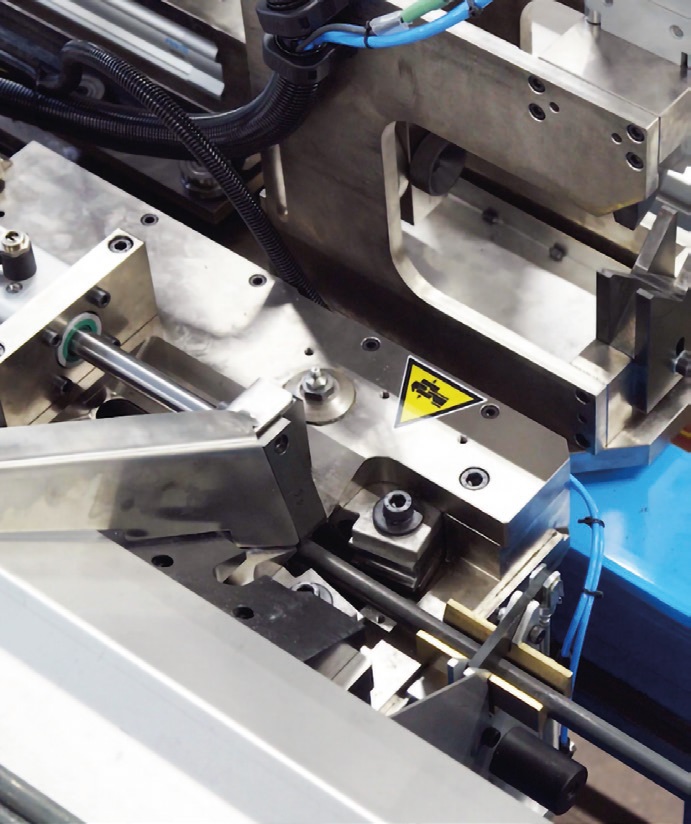

After coil production, it is essential to join the terminals to the conductive contacts, which will later connect to the external circuit. Depending on the required production rate, our coil-pin-plug assembly machines are available with manual, semi-automatic, or fully automatic feeding.

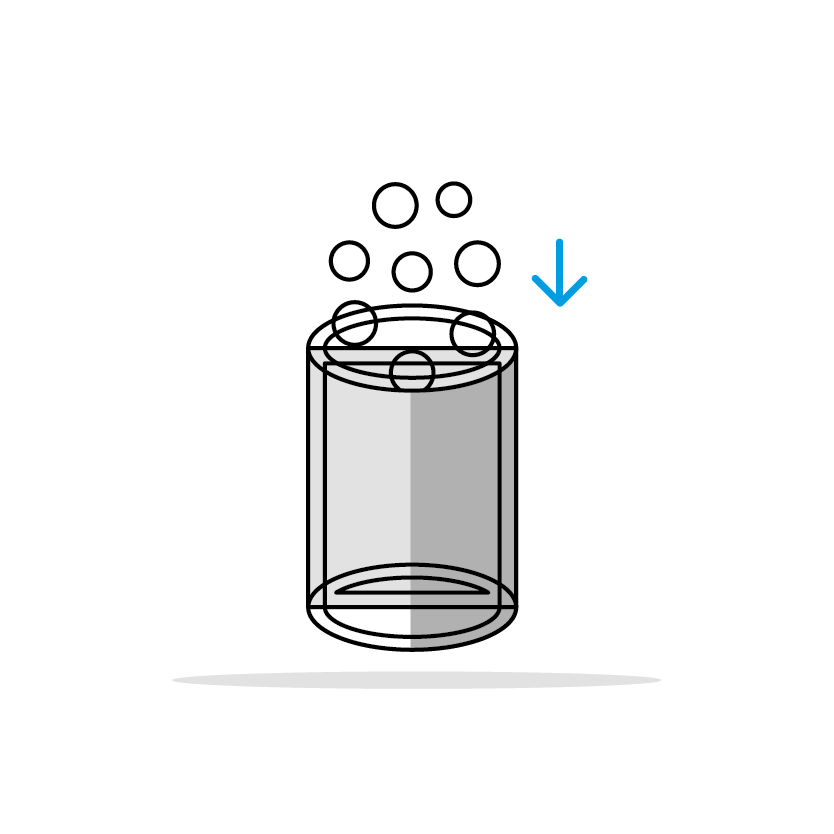

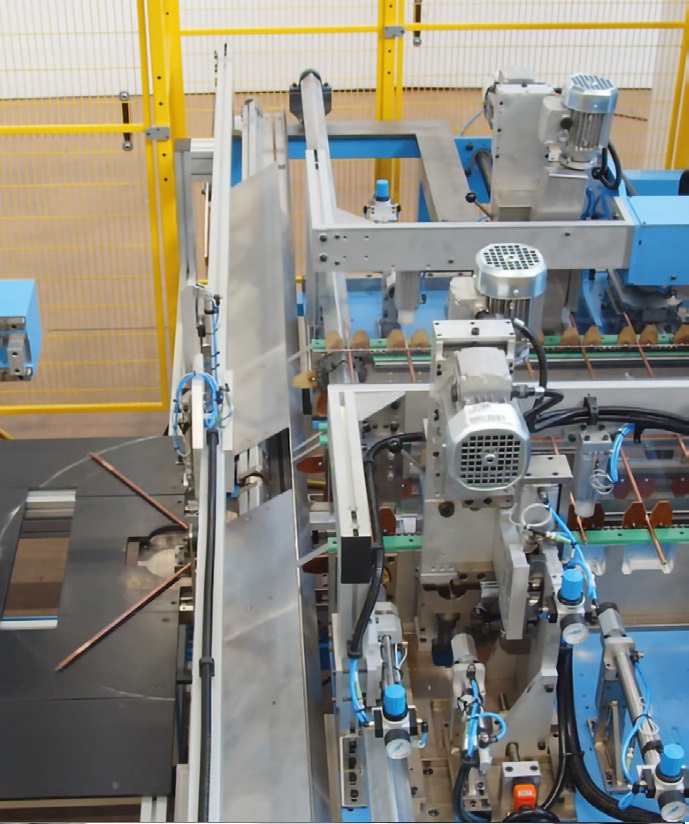

Once assembled, the coils are inserted into the metal tube, which is then filled with magnesium oxide (MgO), a material with excellent insulating properties and thermal conductivity. Through controlled mechanical vibration, the MgO is compacted inside the heating element, eliminating air pockets and ensuring perfect adhesion to the internal walls, uniform insulation, and enhanced performance, reliability, and operational safety.

To optimize timing and resource utilization during the MgO filling phase, it is possible to rely on the combination of multiple dedicated machines, which enable the automation of the entire process. Thanks to intuitive control systems, our machines ensure uniform and precise results, reducing waste and speeding up the production process of electric heating elements.

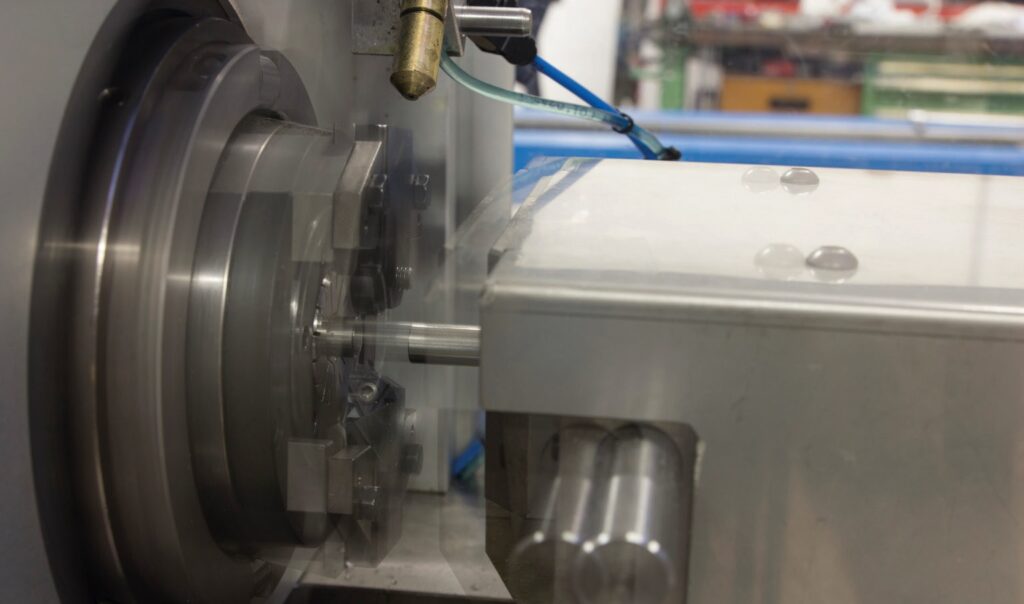

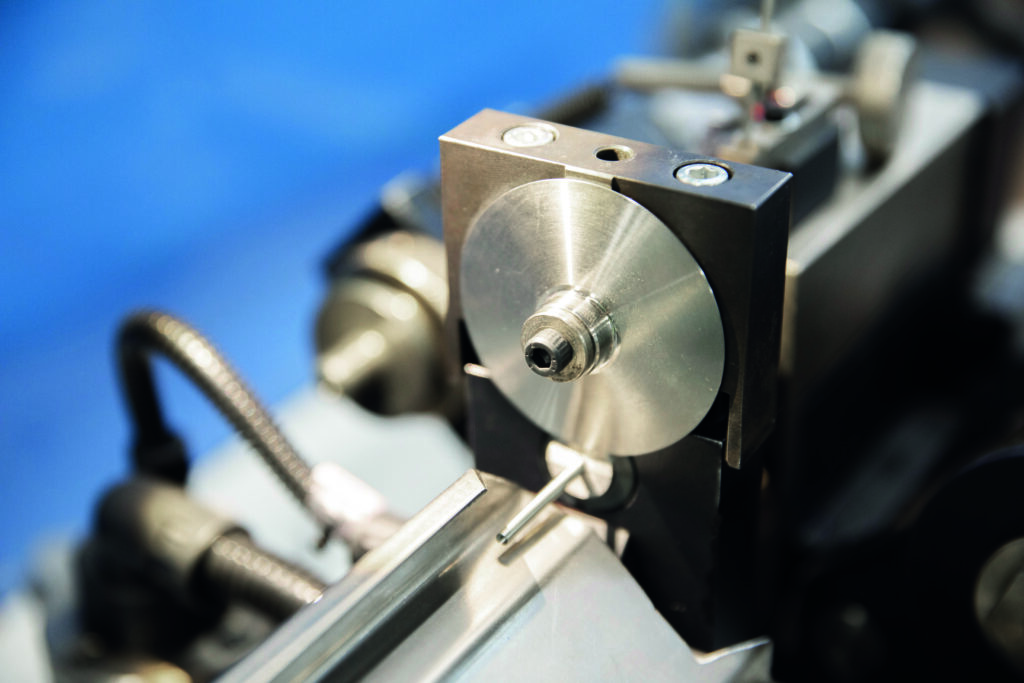

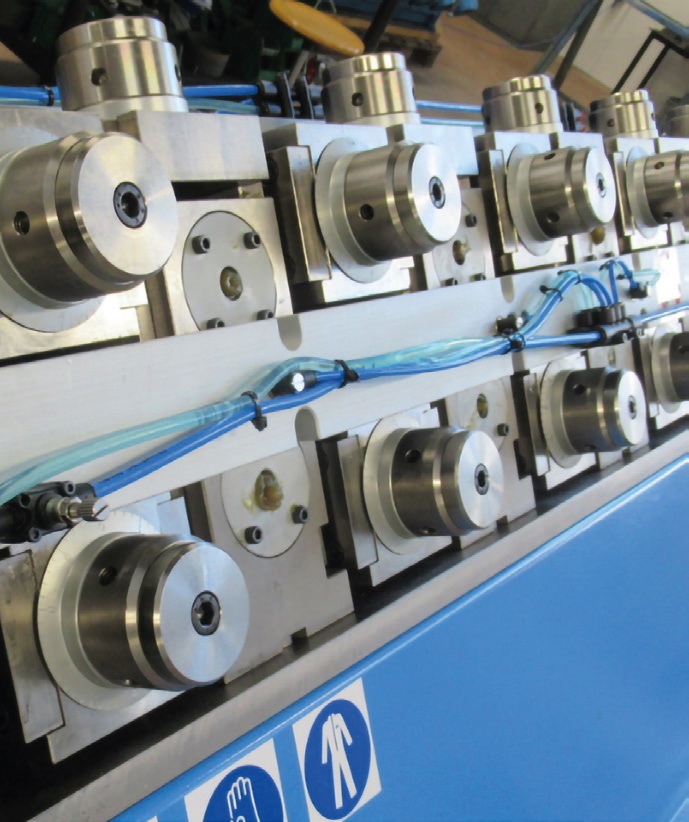

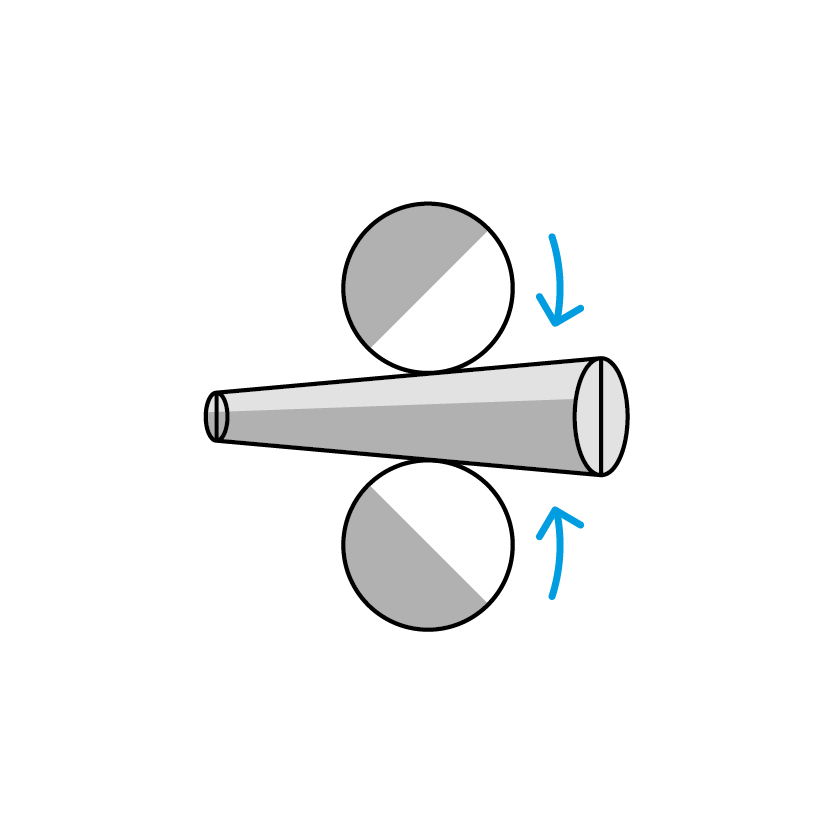

To achieve a uniform diameter and improve the characteristics of the heating element, we use a diameter reduction rolling mill that further compacts the MgO inside the tube. This process creates a watertight barrier, enhancing thermal and electrical performance. For maximum quality and reliability, an electrical testing unit can be integrated to verify compliance with technical specifications.

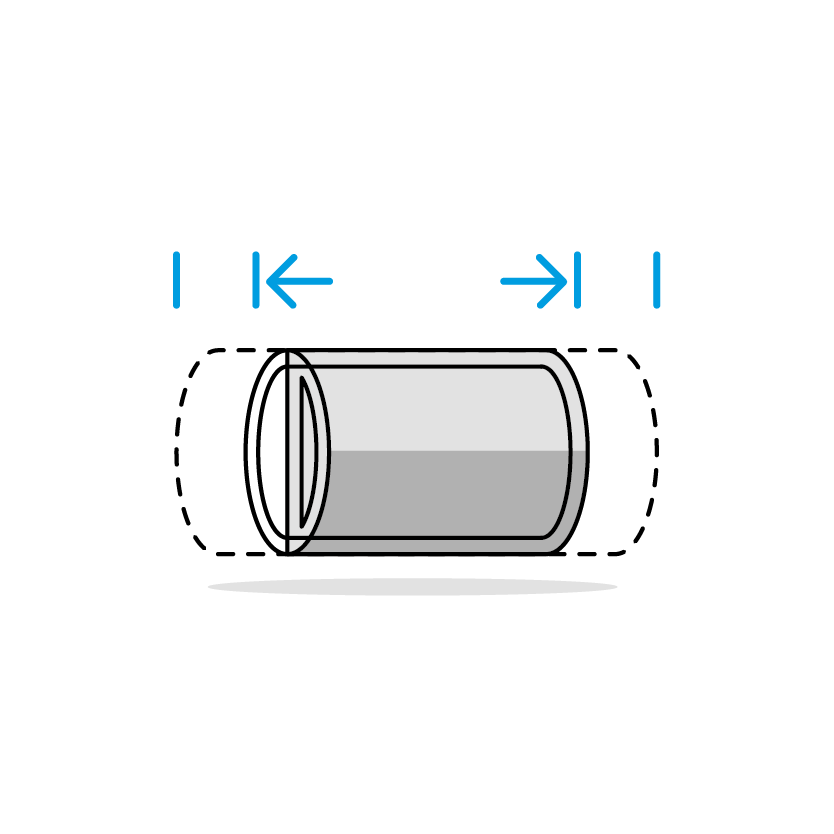

During electric heating element production, dimensional variations of 1–2% can occur. Length compensation distributes these tolerances evenly, preventing heating elements from being too long or too short. This is achieved through length drawing or with an in-line equilong system after the diameter reduction rolling mill.

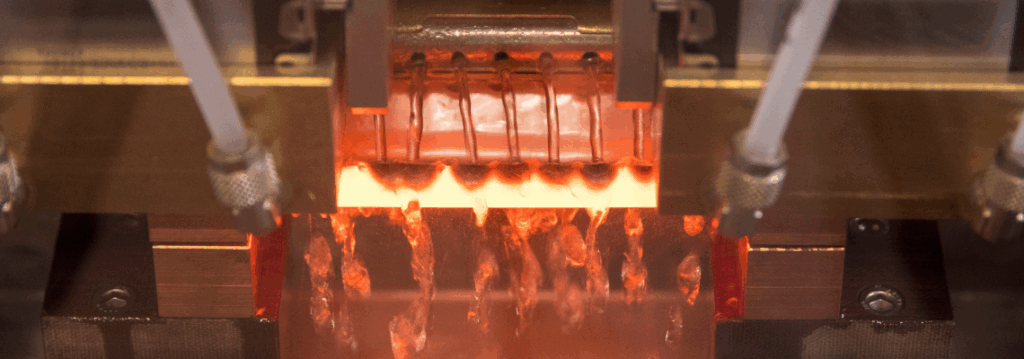

Annealing is a heat treatment that heats the heating element to a specific temperature, holds it for a set time, then cools it slowly. This process eliminates internal mechanical stress, increases ductility, and improves mechanical and electrical properties.

At CSM MACHINERY, we develop automation systems that integrate multiple production processes into a single machine, reducing space requirements, downtime, and boosting productivity. Our machines incorporate customised working units, optimising each production stage to meet client-specific needs.

Electric heating elements are shaped into their final form through bending, carried out by specialised machinery designed to handle different diameters, shapes, and bending angles. We offer a range of bending solutions tailored to your production needs.

Finned heating elements are essential for industrial applications requiring efficient and precise heating. The presence of metallic fins increases the heat exchange surface, enhancing heat dissipation and optimising performance.

Each electric heating element must be tested to ensure proper functionality and compliance with quality standards. Electrical, safety, and functional tests help detect defects and certify a reliable product for the market.

Case studies, applications, and the latest trends on our products and services.