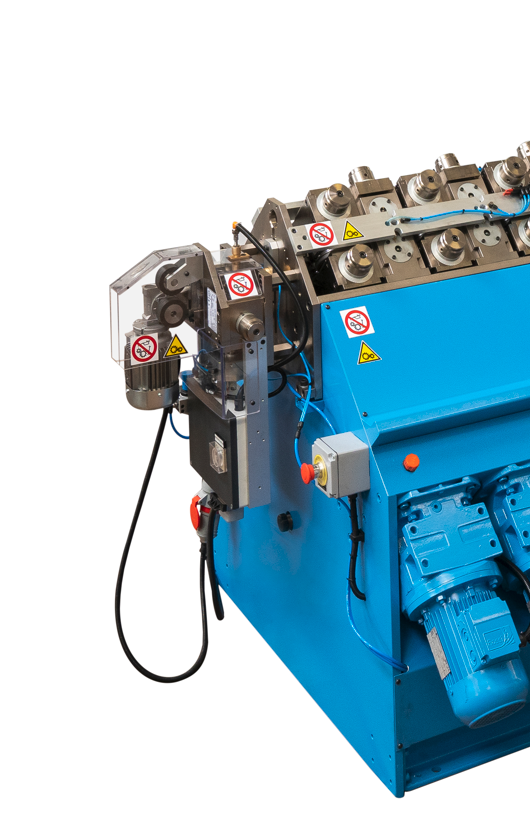

The CSM MACHINERY axial marking is a device that can be installed in line with the rolling mill to mark heating elements along themselves (parallel to the length axis).

The device offers an efficient and versatile solution for identifying heating elements, seamlessly integrating into the production process and delivering high-quality marking results.

The concrete advantages that make the difference

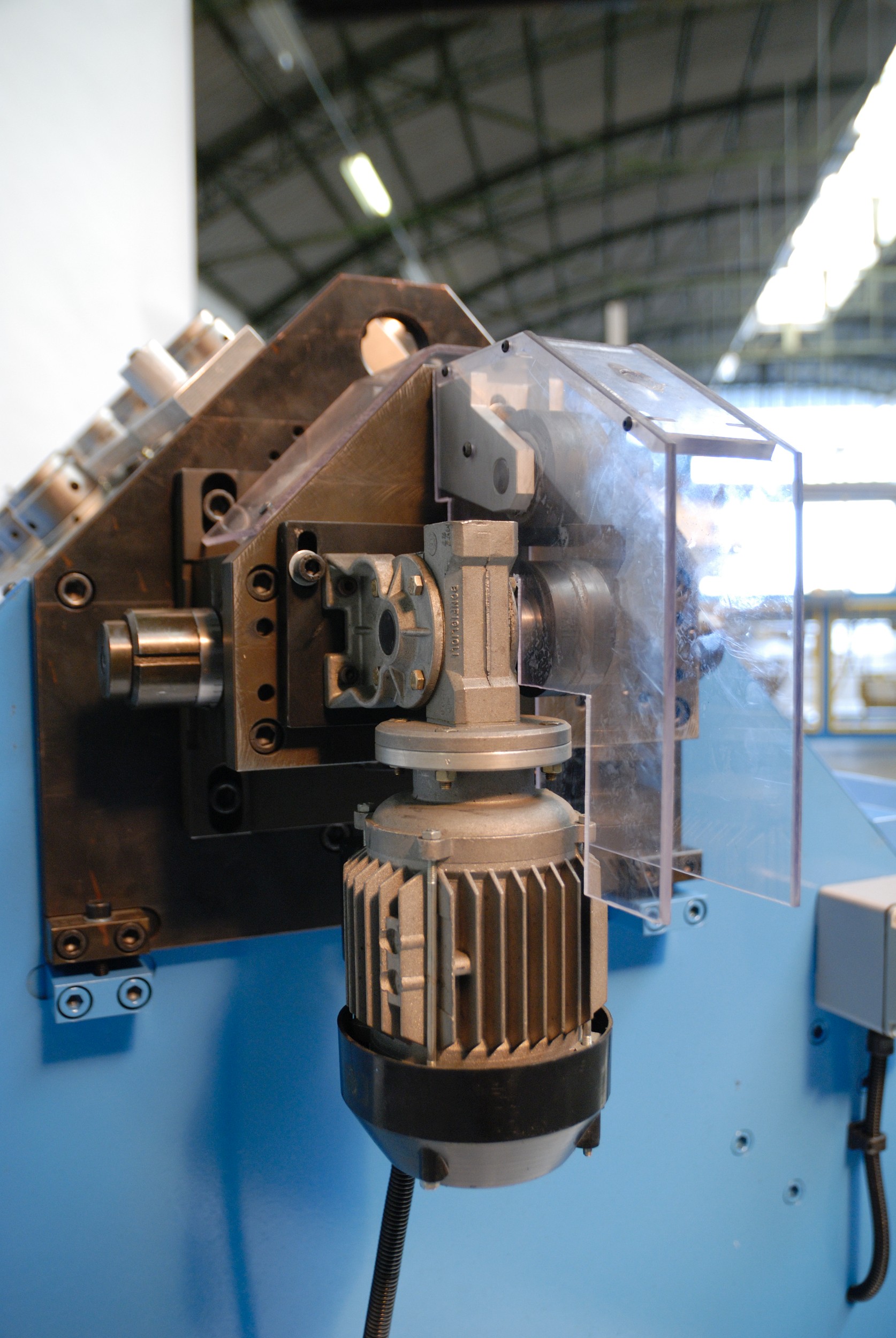

to various tube diameters.

with the reduction mill.

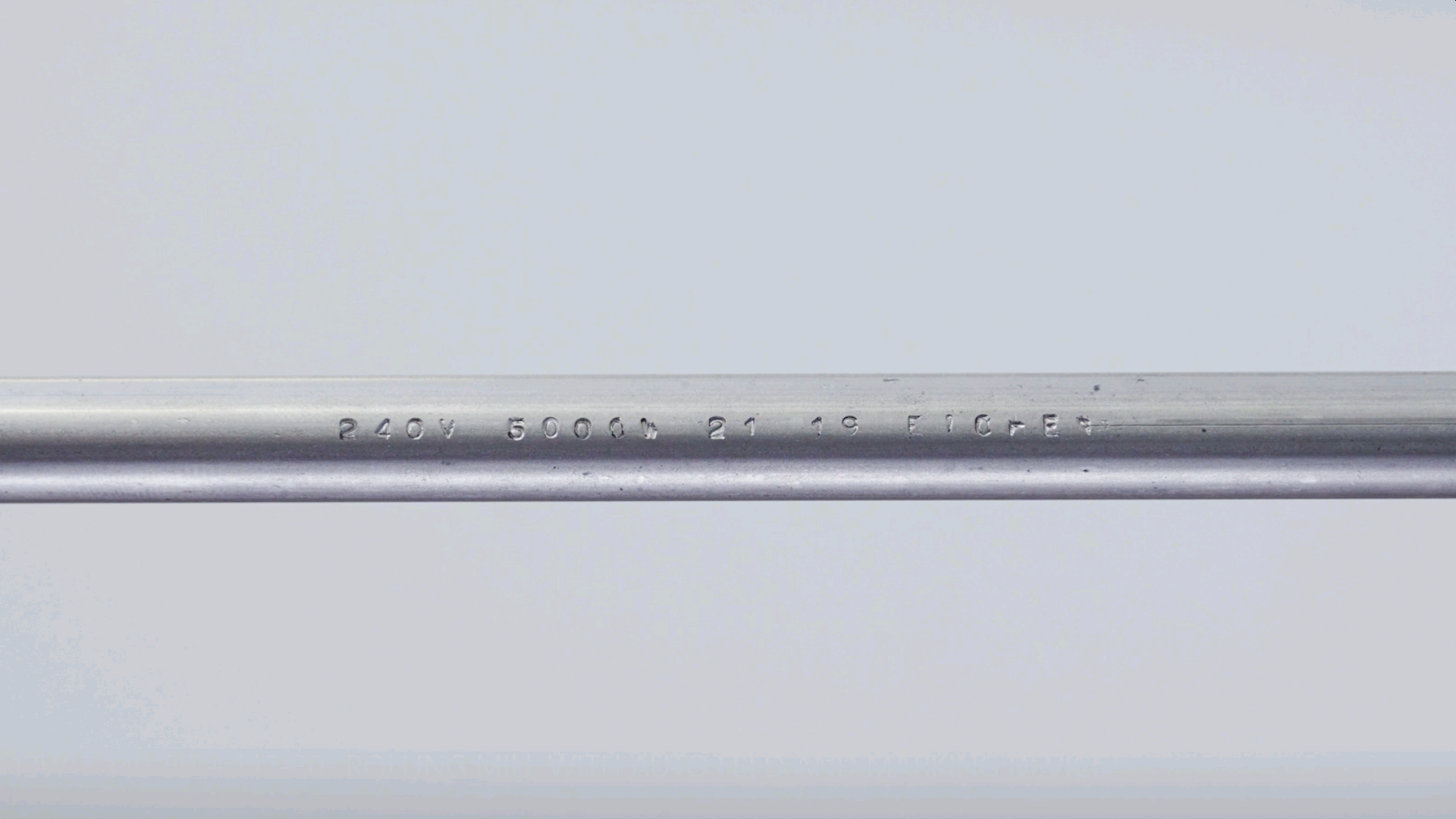

via character wheel displacement.

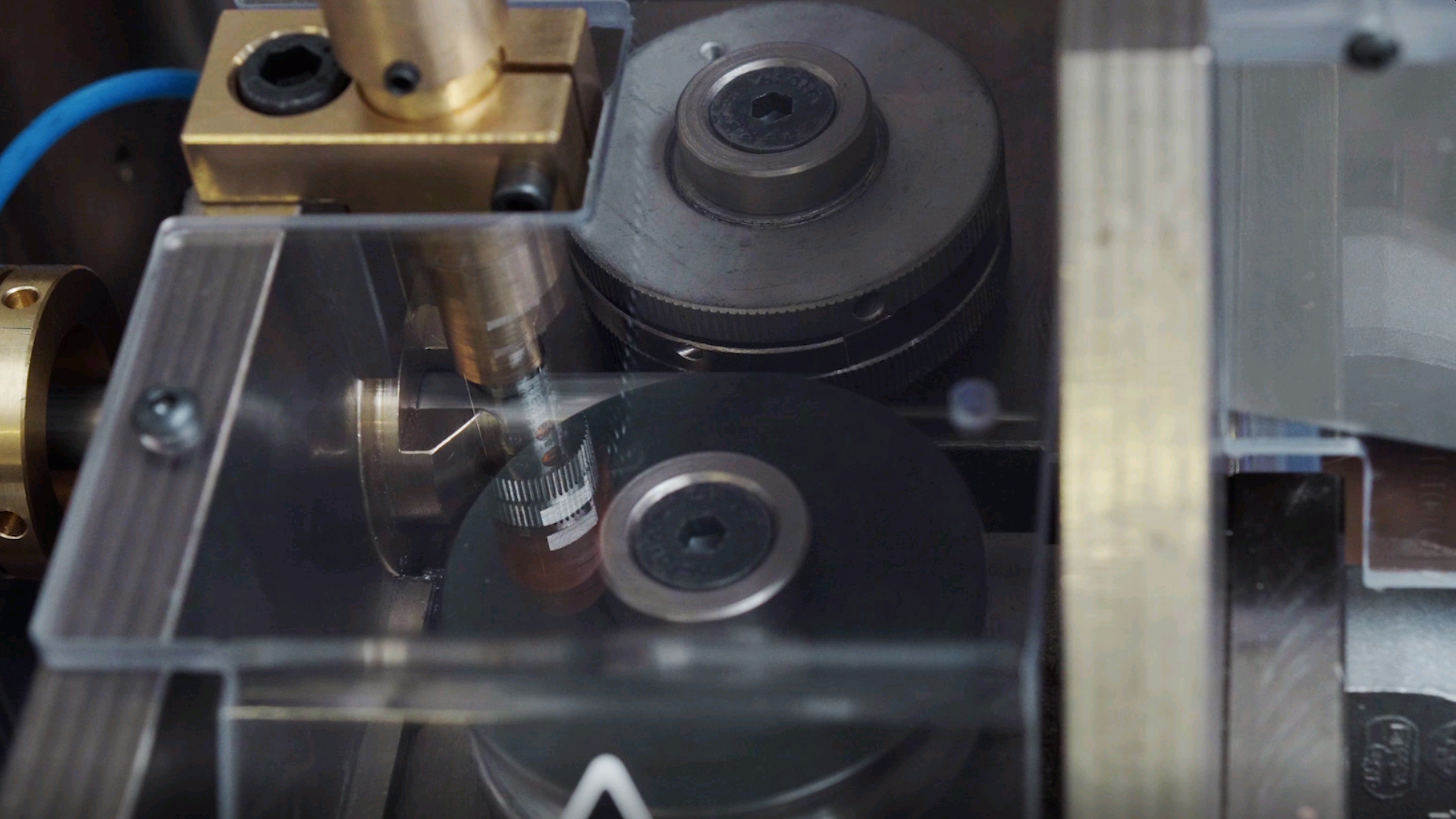

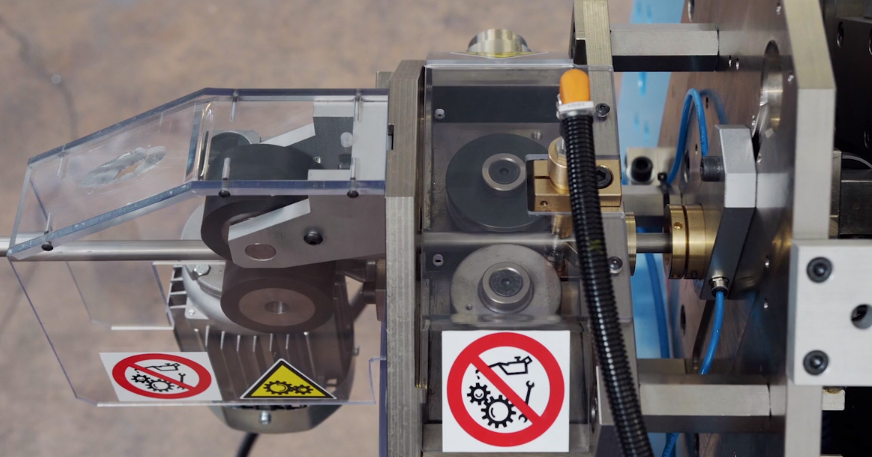

The axial marking system utilizes interchangeable characters, providing flexibility for essential identification data such as voltage (V) and power (W) values, among others. The marking process is seamlessly continuous: the heating element, immediately after exiting the reduction mill, passes through a pair of non-motorized rolls. The first roll is equipped with the selected marking characters, while the second roll functions as a counter-roller, ensuring optimal pressure for a clear and precise engraving.

A fundamental aspect of this device is its practicality. The character-bearing roll is easily removable, simplifying and accelerating character changeover operations. Furthermore, both rollers are equipped with a micrometric adjustment system, which precisely adapts their position according to the specific diameter of the heating element tube, consistently ensuring optimal marking.

The beginning of marking is in a fixed position with reference to the element end.

The beginning of marking is in a programmable position – from 50 to 200 mm with reference to the element end.

The beginning of marking is in a fixed position with reference to the element end.

The beginning of marking is in a programmable position – from 50 to 200 mm with reference to the element end.

Available characters (including spaces) | max 65 |

Character set (numbers/letters) | To be defined |

Tube diameter | min 6 mm, max 16 mm |

Character change time | min 2-3 |

Discover the other products in our range