Increasingly stringent pollution regulations, limiting the type of solvents to be used and the difficulty of disposing of used material has prompted heating element manufacturers to find an alternative to the chlorinated solvents used to degrease coils after coiling.

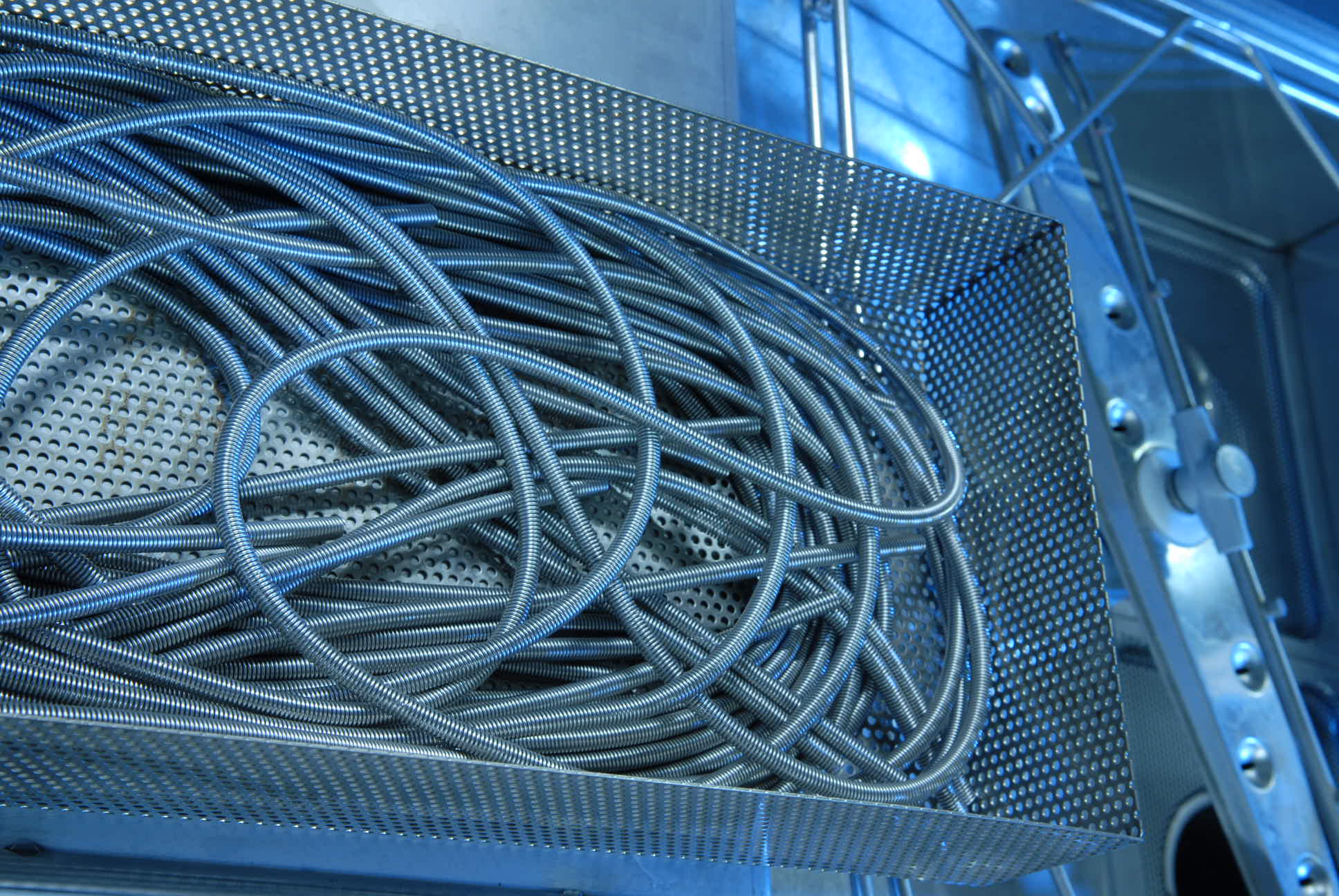

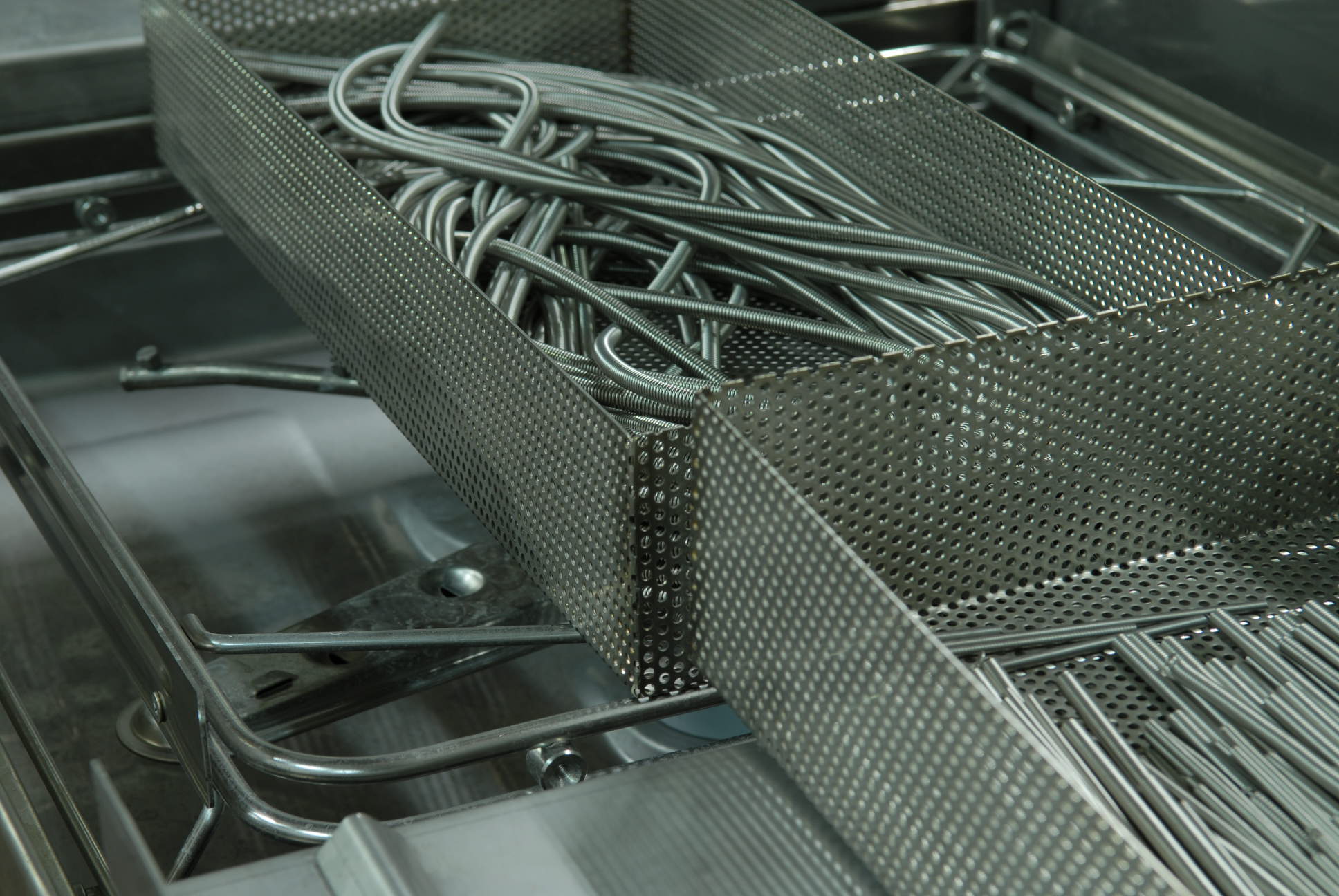

Previously, the main problem was the use of mineral oils to help wind the wire around the spindle. To overcome this, CSM MACHINERY uses a water-soluble, biodegradable lubricant where most of the components are soap and a small amount of vegetable oils. Our spiral washing system uses hot water and soap on modified conventional dishwashers to remove the small amounts of lubricant used during spiraling. Small amounts due to our lubricant being precisely used in a solution of 5% lubricant and 95% water.

The concrete advantages that make the difference

using a water-soluble and biodegradable lubricant.

providing post-processing flexibility.

for programs up to 12 minutes.

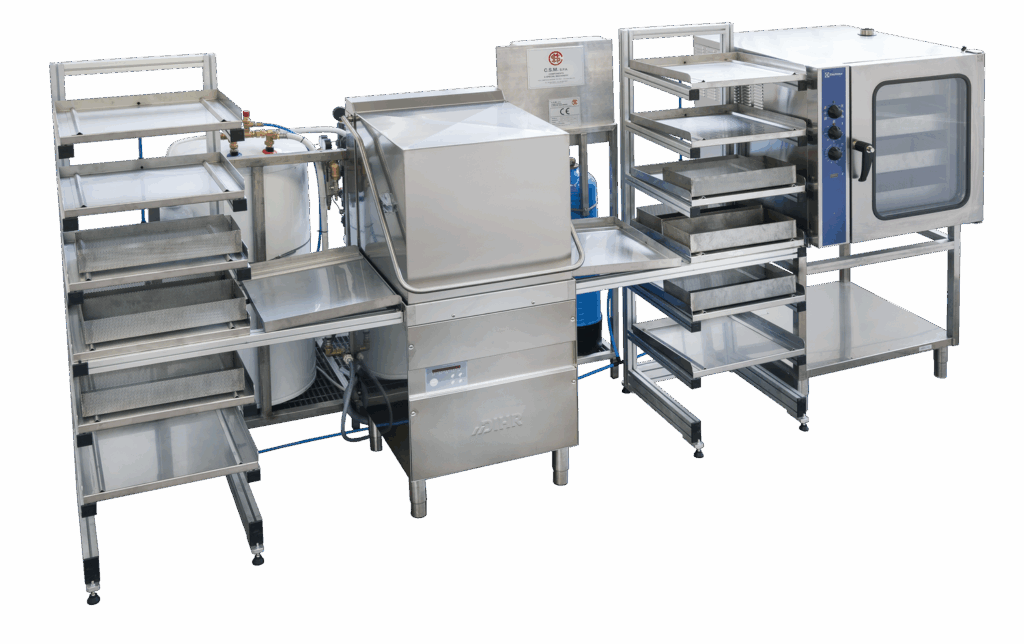

CSM MACHINERY’s system to clean coils features a stainless steel structure that integrates a washing unit, a draining section, and a drying oven. It includes customized solutions for water treatment, a gas or electric boiler, and ten dedicated tanks for the spirals.

Thanks to our advanced technologies, this process ensures perfect results on open coils, allowing water to penetrate between the coils and effectively remove biodegradable lubricant. Even on “closed” spirals, the system’s effectiveness is comparable to traditional methods using chlorine solvents, as conventional solvents often struggle to clean trapped mineral oil residues.

Power supply | 400 3 N/50 V/Hz |

Installed power | 25 KW |

Additional utilities | Water, methane |

Washing: max. quantity of coils per tray | 2,5 - 3 Kg |

Typical washing time | 15 min. |

Water per cycle (rinsing) | 4 - 5 l. |

Drying: shelves | n. 7 |

Drying: trays per level | n. 2 |

Weight | 590 Kg |

Dimensions | To be defined (mm) |

Discover the other products in our range