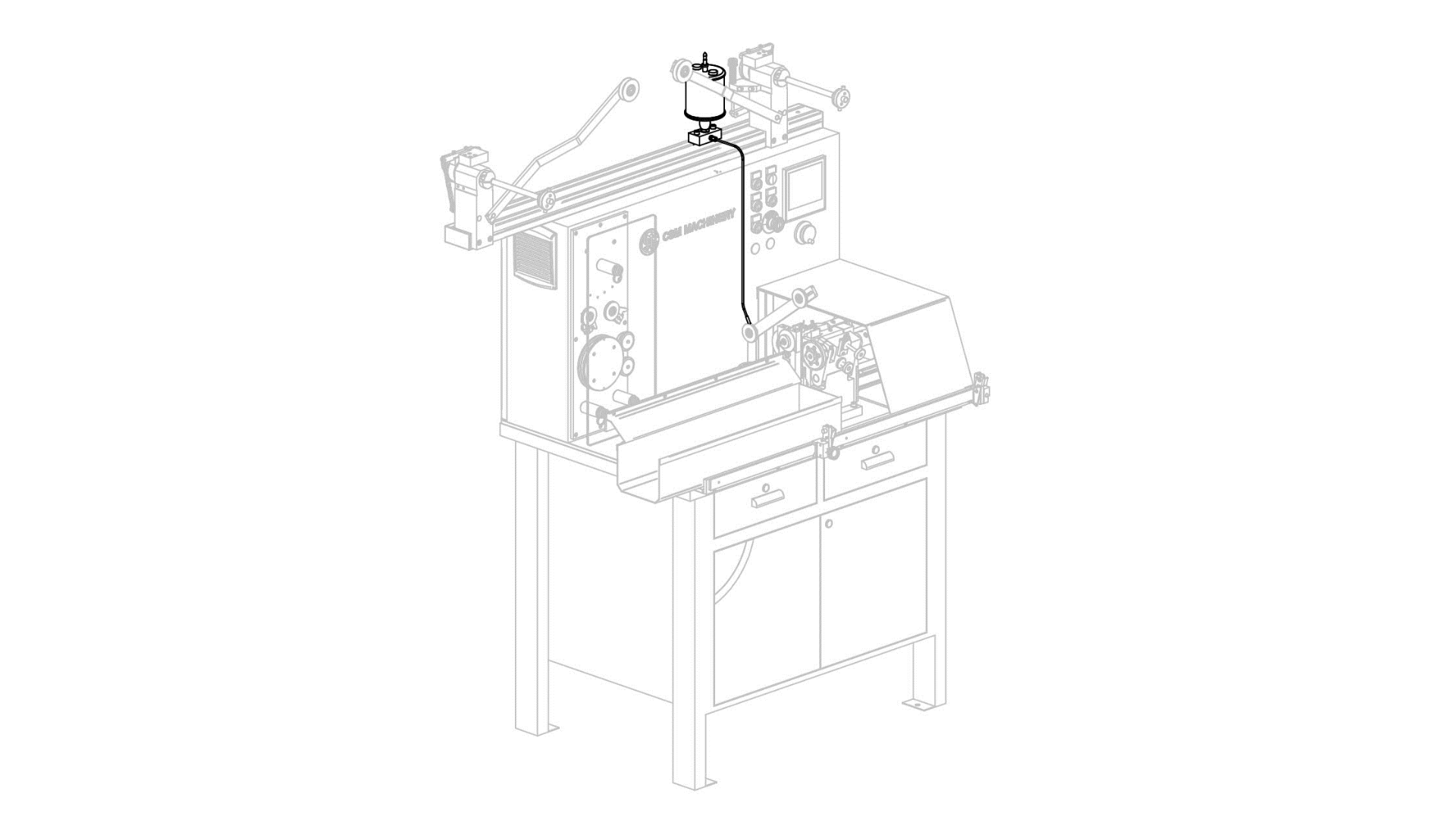

CSM automatic coil winding machine is defined by speed, ease of use, maintenance, and precise cutting solutions, ensuring high performance of coiling in line with the latest quality standards.

Completely electronic and automatized, CSM MACHINERY coiling machine is equipped with an electronic system for constant control and auto-calibration of the ohmic value on the coil. This system enables the detection of wire sections outside tolerance and potential wire tension issues.

The concrete advantages that make the difference

produced during cutting due to the high-precision positioning of the cutting blade.

with an automatic electronic system.

without the need for operator supervision.

in case of wire entanglement on the spindle.

with an intuitive touchscreen operator interface.

achieved through the use of DC motors.

Discover all the machine details

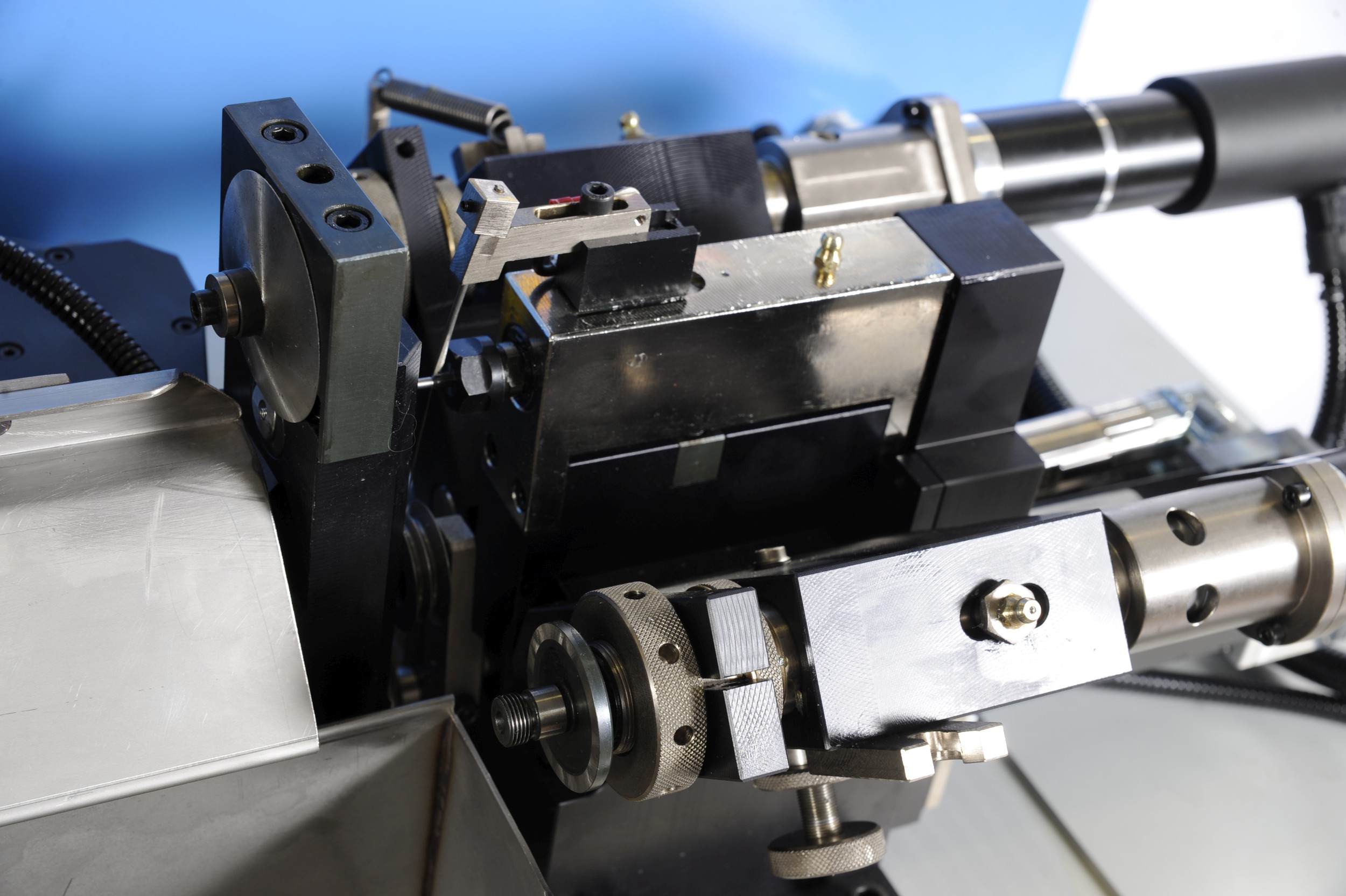

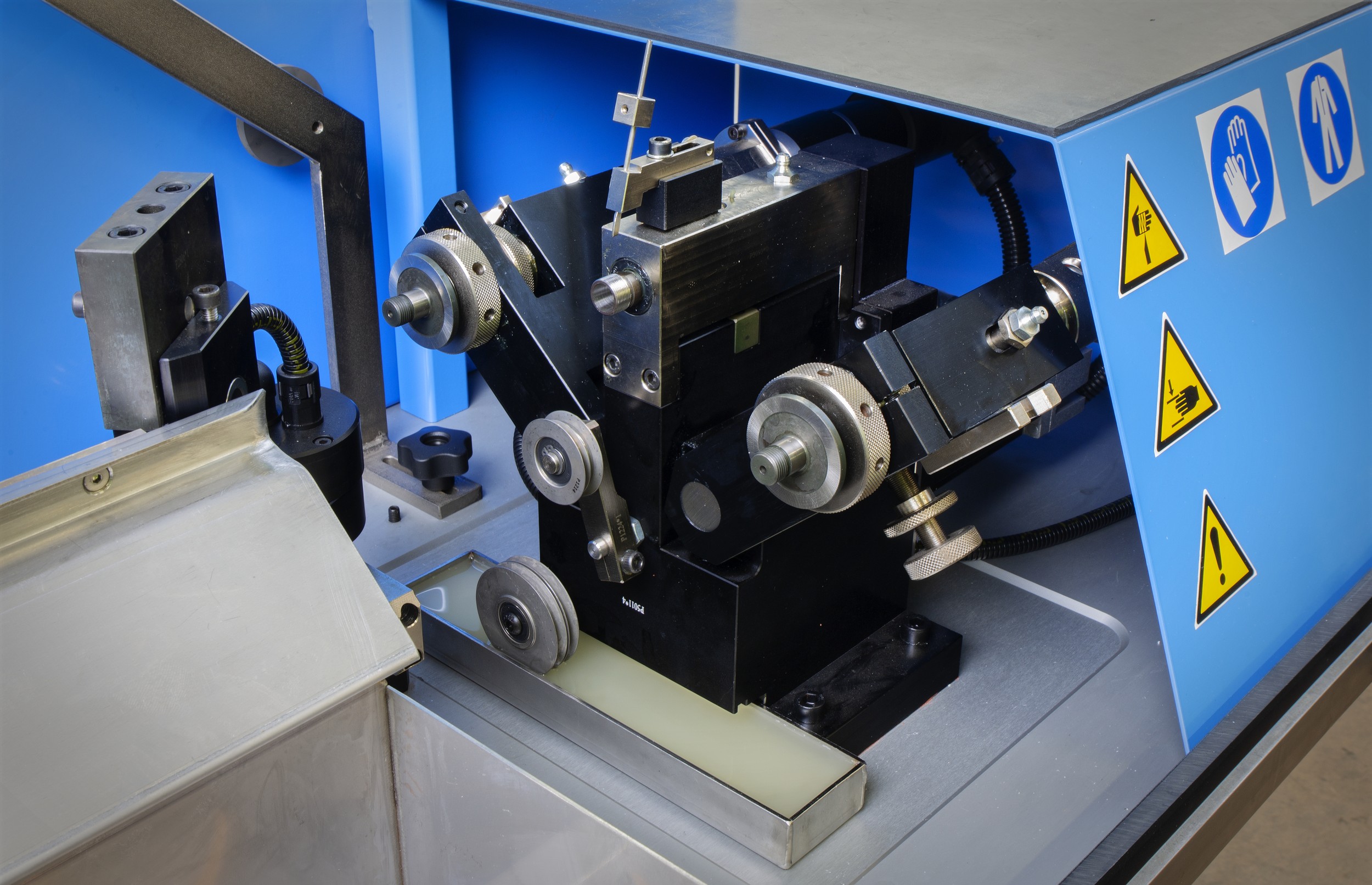

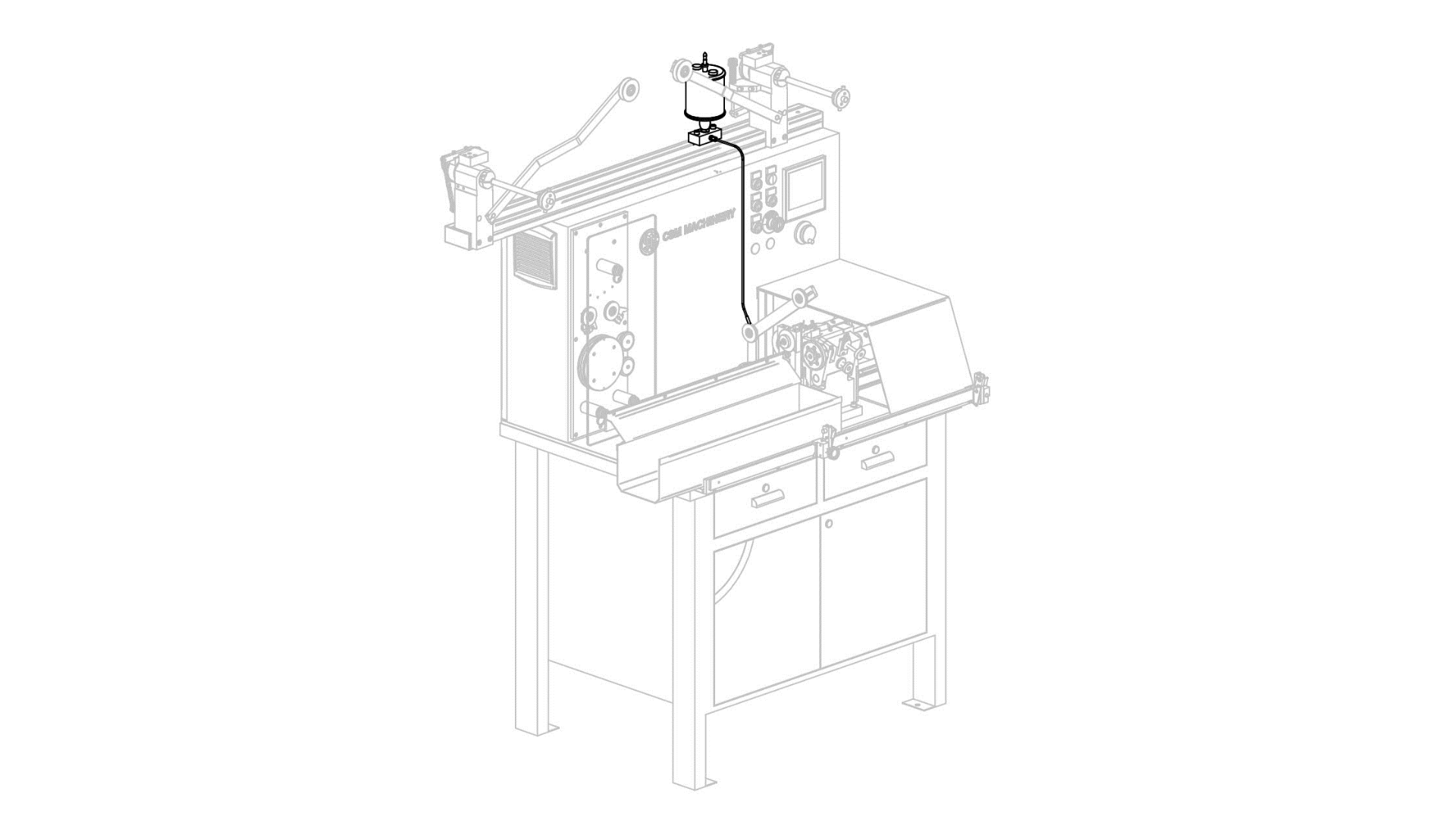

REACTIVE BRAKE

Mechanic braking system to set the required wire tension.

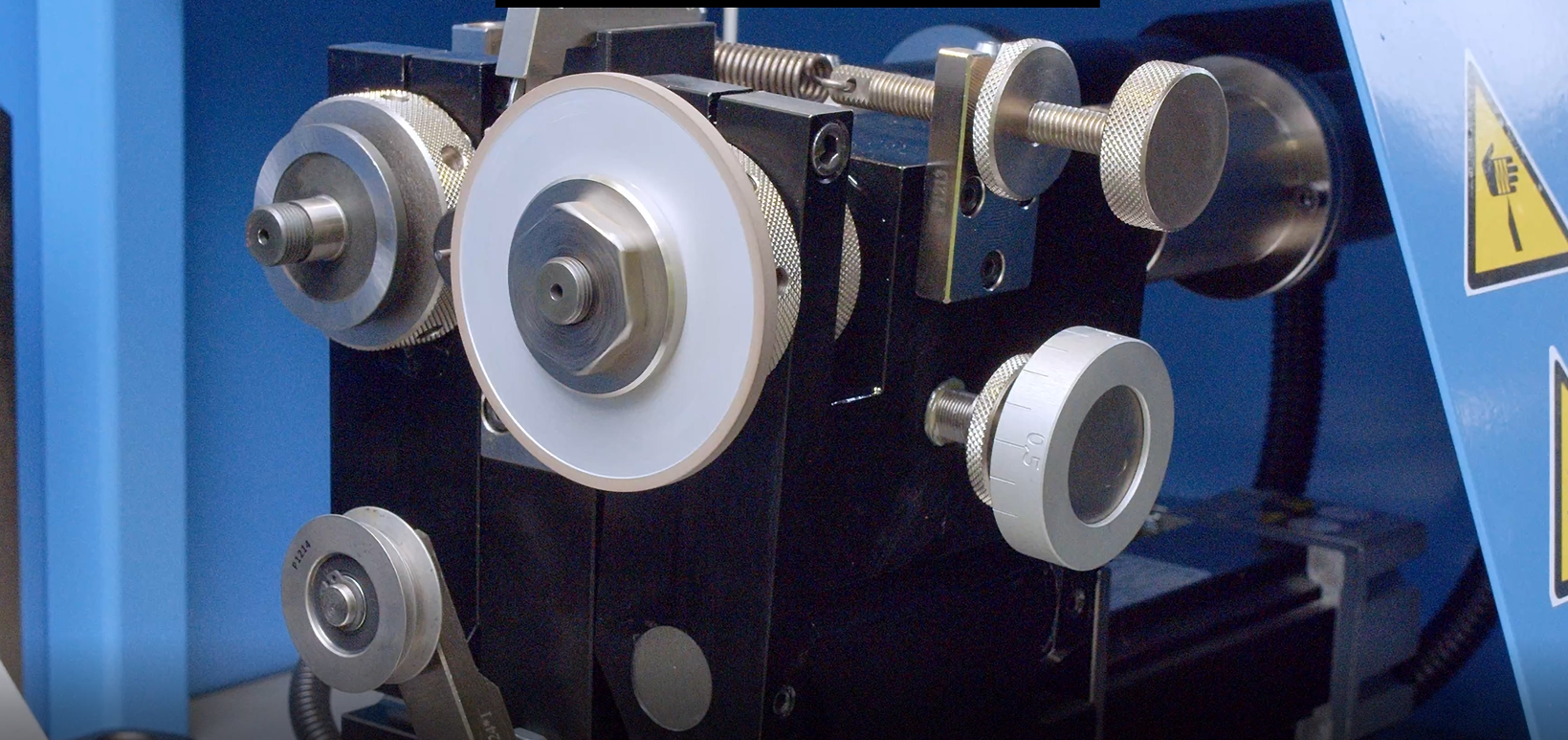

DEVICE FOR CONTINUOUS MEASUREMENT OF WIRE OHMIC VALUE AND WIRE LENGTH (ENCODER)

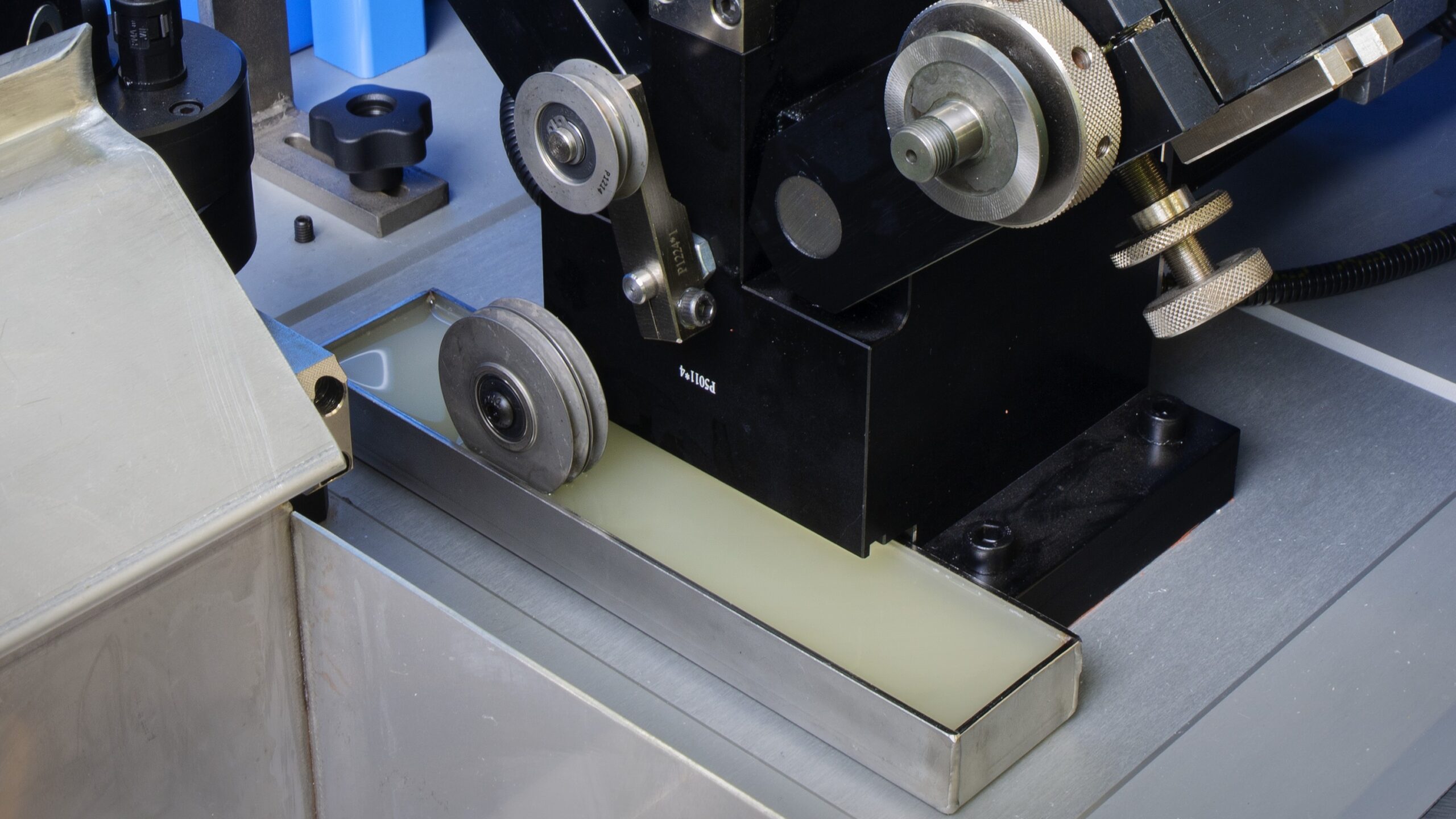

HOPPER TO COLLECT COILS AFTER THE CUTTING OPERATION

WORK BENCH, COMPLETE WITH DRAWERS

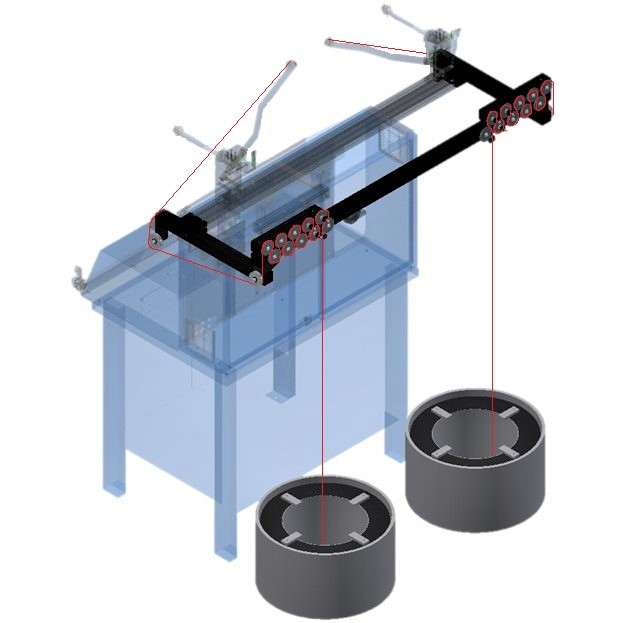

2 COIL HOLDERS FOR RESISTIVE WIRE

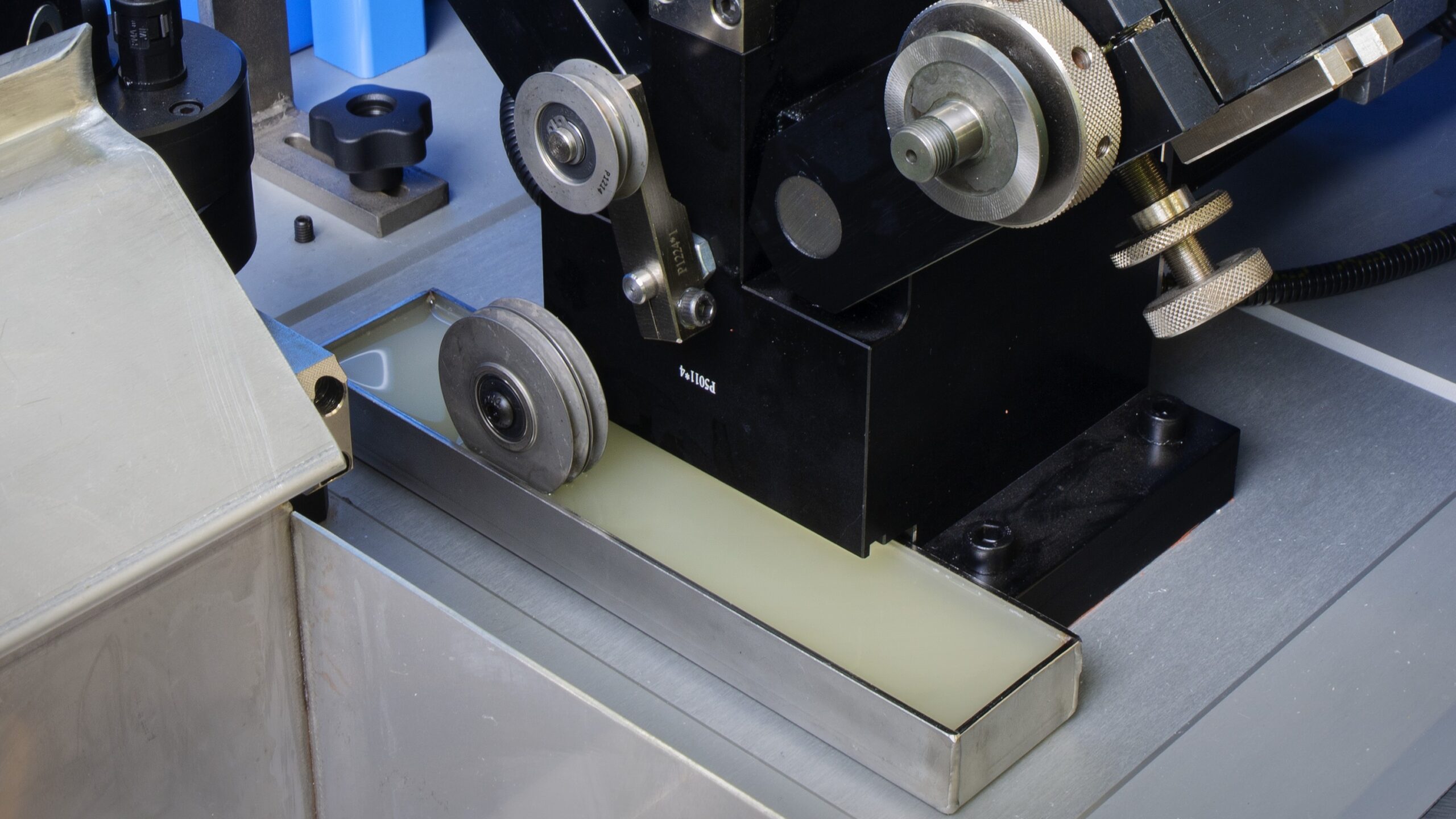

CUTTING DEVICE

operated by a d.c. motor

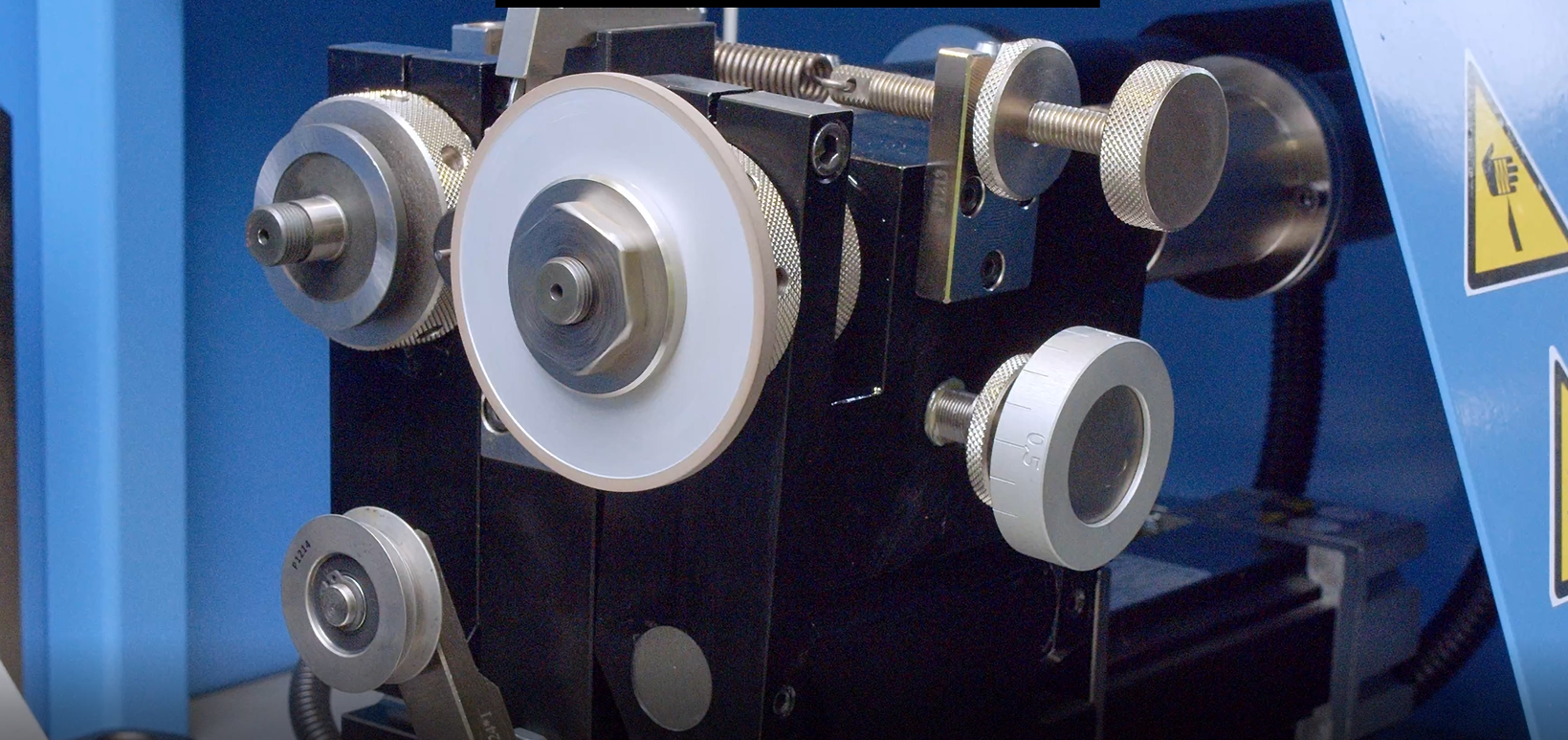

COIL SPACE WINDING

System to separate coils through cutting blade, for wire diameter greater than 0,25 mm (.010 inch). Possibility to program up to 100 separations with definition of the separation field either in ohmic value, number of coils or percentage of the total nominal ohmic value of the coil.

DEVICE TO CHECK

the ohmic value of the first coil produced and also used for the automatic self-calibration of the machine at the set ohmic value.

MANDREL GROUP

to wind the coil, driven by a brushless motor.

2 THRUST (SUPPORT) WHEEL GROUP

pushed against the mandrel so that the coil can be wound. They are operated by a d.c. motor.

The standard coil offloading tray is fixed and has a length of 670 mm (26.38 in). Longer trays are available, as detailed in the table within the technical data sheet. In the case of the production of long coils, the use of pneumatic offloading systems is recommended. When producing longer elements, a longer system of static ohm measurement is recommended.

Device for unwinding and tensioning wire in drums or pail packs. max wire size 1,8 mm (.071 in).

Software patch to manage ethernet interface. It allows remote access to the machine.

It is possible to produce coils with single wire, wire diameter < 0,09 mm (.004 in) and mandrel diameter < 0,60 mm (.024 in) using this special kit.

Device to verify calibration to the coiling machines. Dynamic and static ohmic testing is provided complete with mechanical connectors to measure wheel, box with certified test resistors and set of connection cables.

The standard indicator light is orange color. The 3-color indicator light allows the use of color to indicate the machine status (green: machine in use; yellow: machine during setting or production batch ready; red: machine in alarm).

Lubricant specially developed for coiling machines biodegradable and to be washed away with water.

The dispenser restores the level of lubricant in the lubricant basin. It is recommended in case the machine works without frequent surveillance.

The standard coil offloading tray is fixed and has a length of 670 mm (26.38 in). Longer trays are available, as detailed in the table within the technical data sheet. In the case of the production of long coils, the use of pneumatic offloading systems is recommended. When producing longer elements, a longer system of static ohm measurement is recommended.

Device for unwinding and tensioning wire in drums or pail packs. max wire size 1,8 mm (.071 in).

Software patch to manage ethernet interface. It allows remote access to the machine.

It is possible to produce coils with single wire, wire diameter < 0,09 mm (.004 in) and mandrel diameter < 0,60 mm (.024 in) using this special kit.

Device to verify calibration to the coiling machines. Dynamic and static ohmic testing is provided complete with mechanical connectors to measure wheel, box with certified test resistors and set of connection cables.

The standard indicator light is orange color. The 3-color indicator light allows the use of color to indicate the machine status (green: machine in use; yellow: machine during setting or production batch ready; red: machine in alarm).

Lubricant specially developed for coiling machines biodegradable and to be washed away with water.

The dispenser restores the level of lubricant in the lubricant basin. It is recommended in case the machine works without frequent surveillance.

To allow the formation of 3-wire coils, the following support must be provided:

DYNAMIC SUPPORT TO ALLOW 3-WIRE WINDING, Mod. 125/29.000310 composed by:

To allow the formation of 3-4 wire coils, the following support must be provided:

DYNAMIC SUPPORT TO ALLOW 3-OR 4 WIRE WINDING, Mod. 125/29.000320 composed of:

The largest wire diameter when winding 4-wire coils is 0,7+0,7+0,7+0,7 mm.

To allow the formation of 3-wire coils, the following support must be provided:

DYNAMIC SUPPORT TO ALLOW 3-WIRE WINDING, Mod. 125/29.000310 composed by:

To allow the formation of 3-4 wire coils, the following support must be provided:

DYNAMIC SUPPORT TO ALLOW 3-OR 4 WIRE WINDING, Mod. 125/29.000320 composed of:

The largest wire diameter when winding 4-wire coils is 0,7+0,7+0,7+0,7 mm.

Standard wire spools type, up to | 250 DIN |

Length of the standard coil offloading system | 670 mm (26.38 inch) |

Max number of mandrel revolutions | 6000 rev/min. |

Product codes to be stored (wire Ø - alloy - mandrel Ø - 1-2 wire coil) | n. 2000 |

Max. batches to be set (same product code) | n. 20 |

Precision on final coil ohmic value (depending on speed) | ± 0,5 - 0,8 % ohm |

Electric supply | L+N/PE V |

Total installed power | 1 kVA |

Machine dimensions | 1340x845x1845h mm |

Weight | 230 kg |

Discover the other products in our range