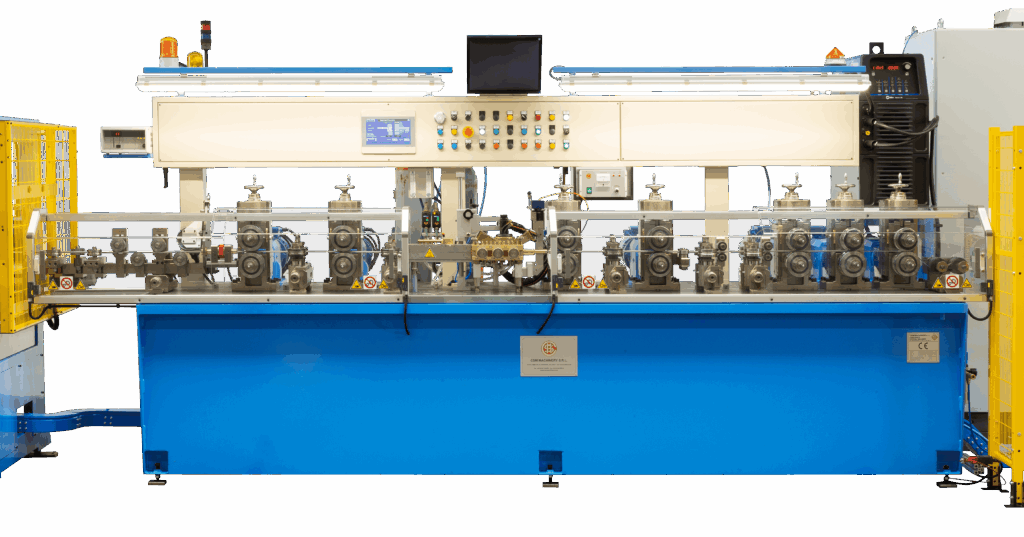

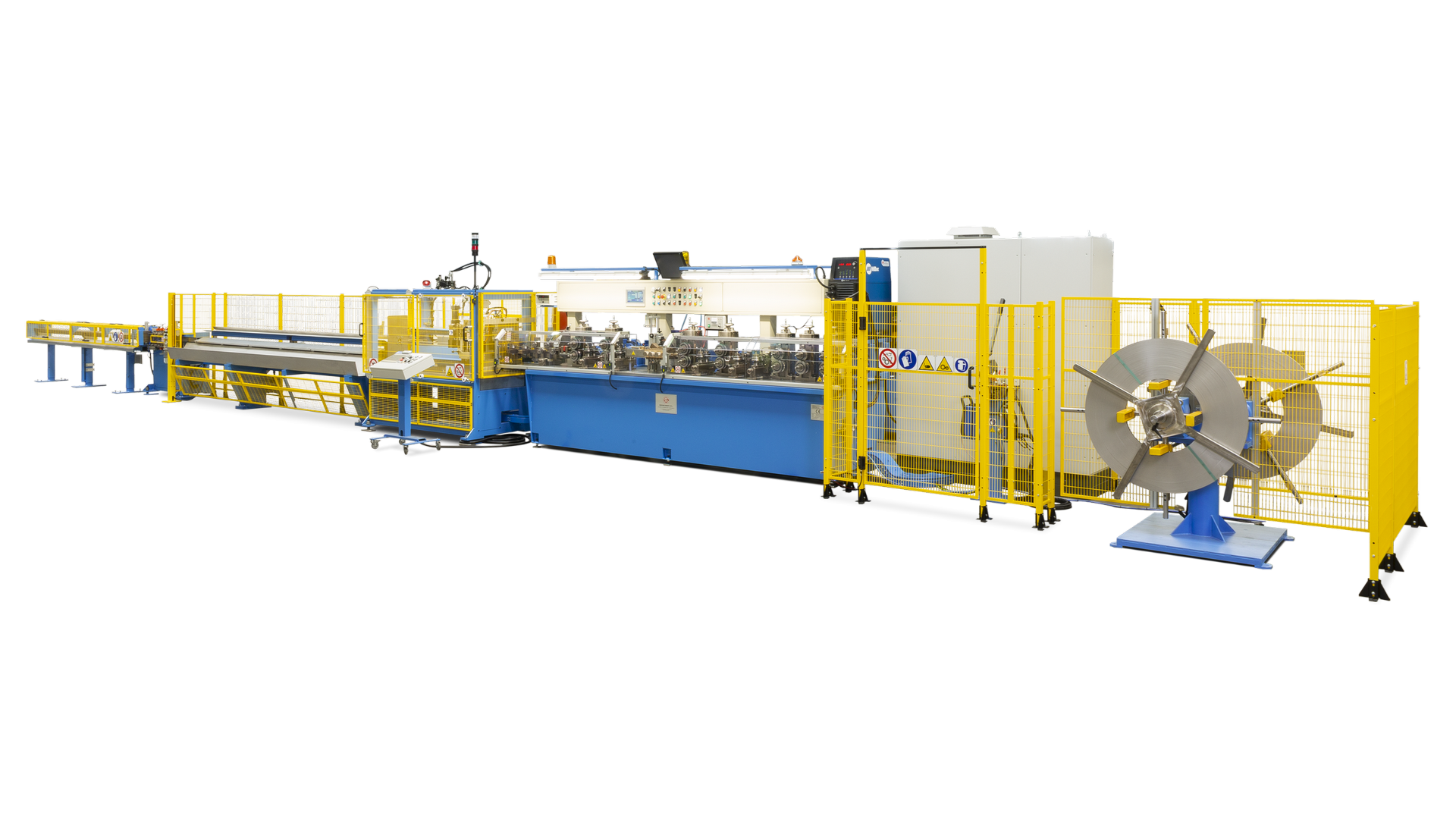

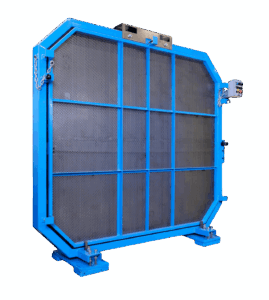

CSM MACHINERY offers a new generation of machines designed to form, weld, cut to length, straighten, and calibrate stainless steel tubes. This type of machine has a quick set-up thanks to the operator interface that gives the possibility to recall stored parameters according to the type of product. This aspect gives the capability increase production capacity, while minimizing downtime. Moreover, simply by setting the desired lengths and quantity, it is possible to create a completely ready-to-use straightened tubes with sized ends.

The forming and welding line for welded tubes is available in two versions: our standard solution for tubes with a diameter between 6 mm and 16 mm and our heavy-duty solution for tubes with a diameter ranging from 10 to 28 mm.

The concrete advantages that make the difference

thanks to the quick setup and possibility to recall stored parameters.

to minimize downtime and to ensure seamless production.

for maximum application versatility and flexibility.

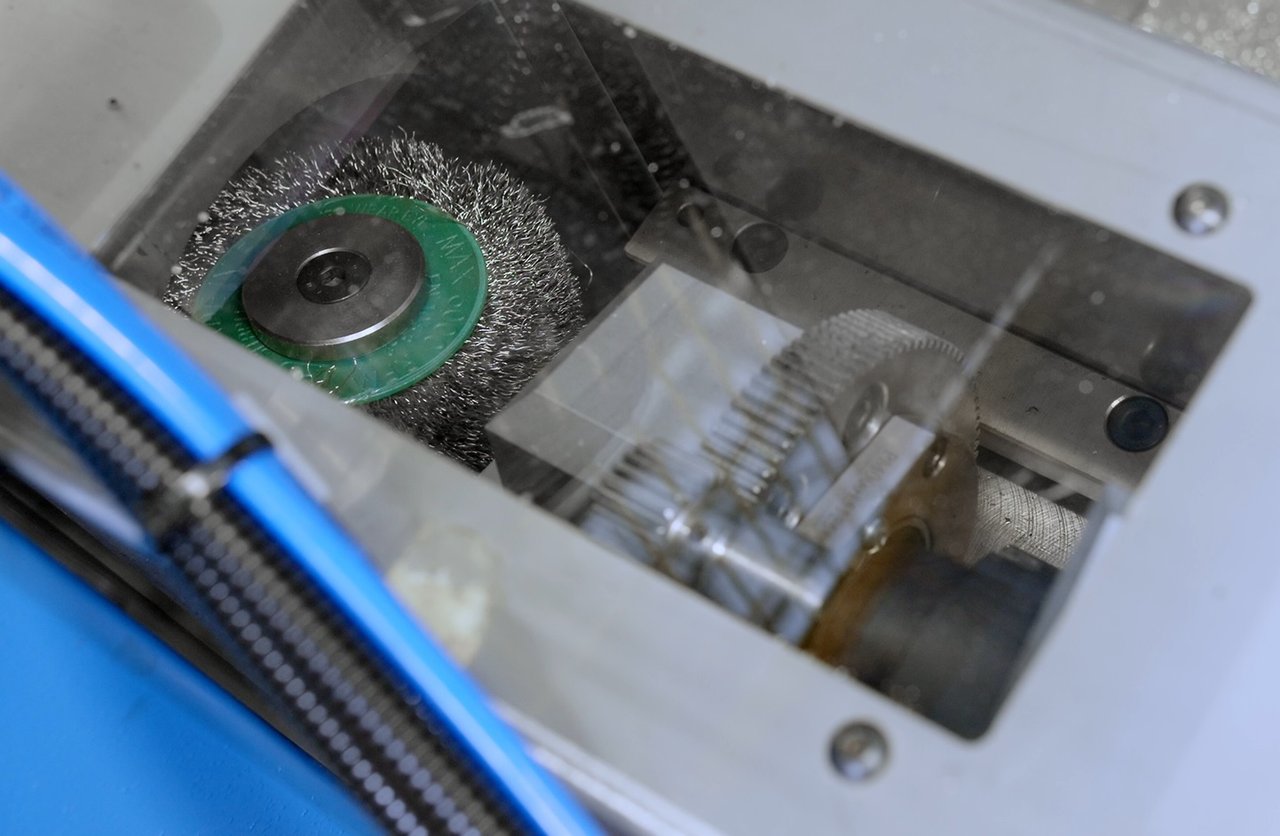

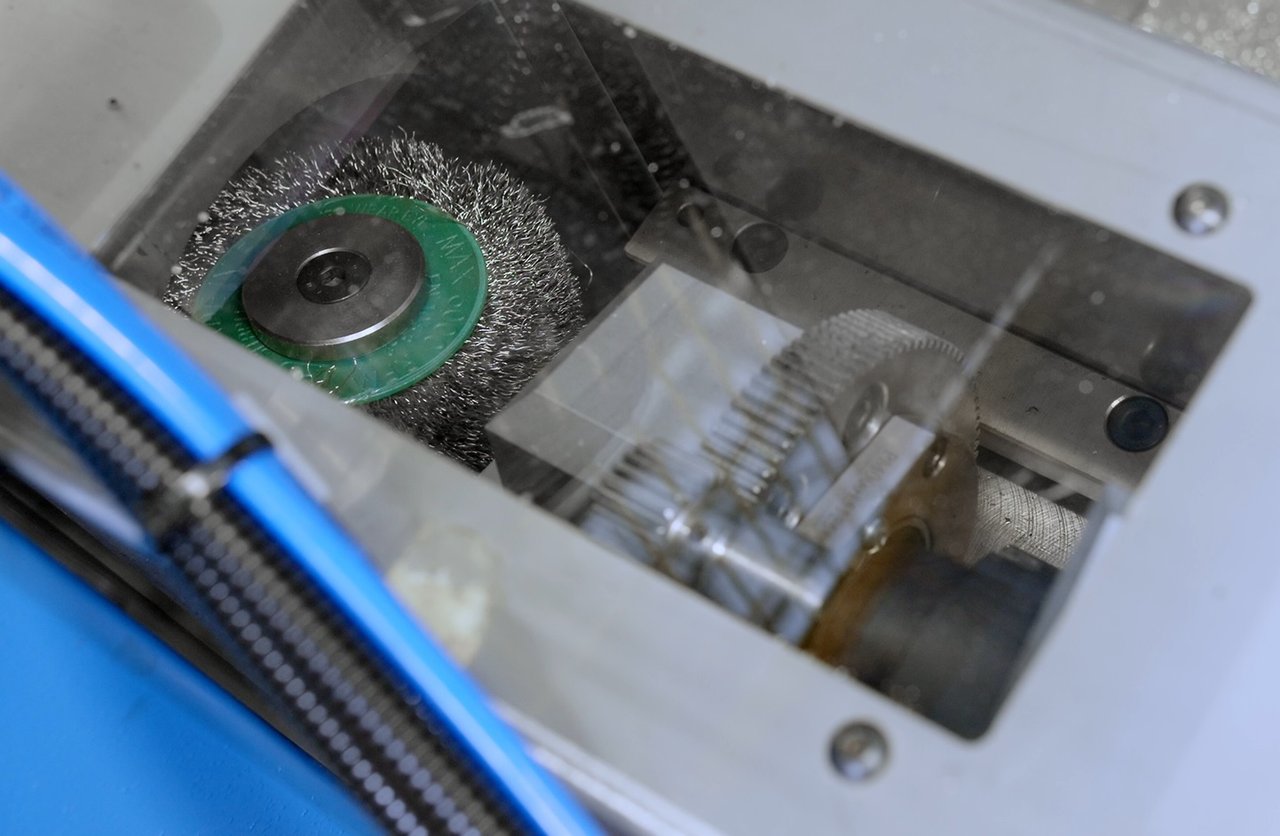

for accurate results: clean strip edges free of oxidation.

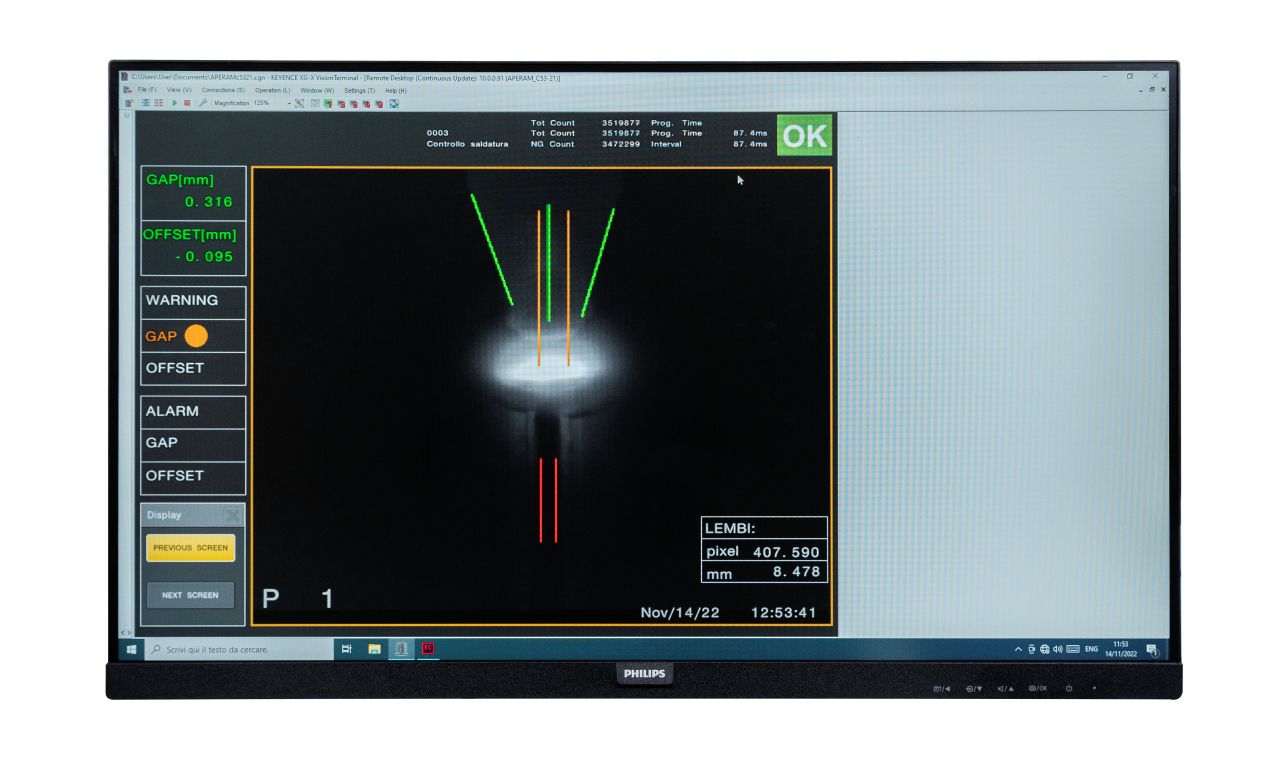

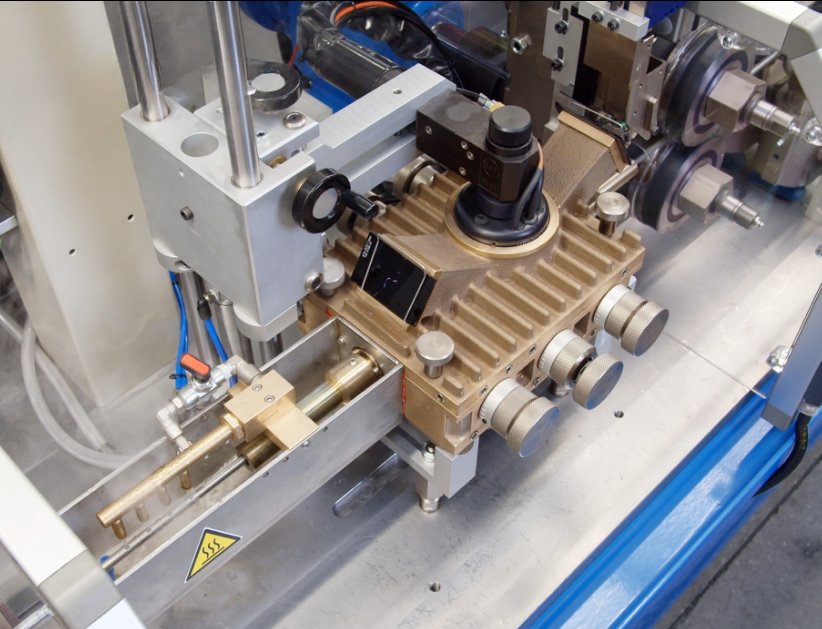

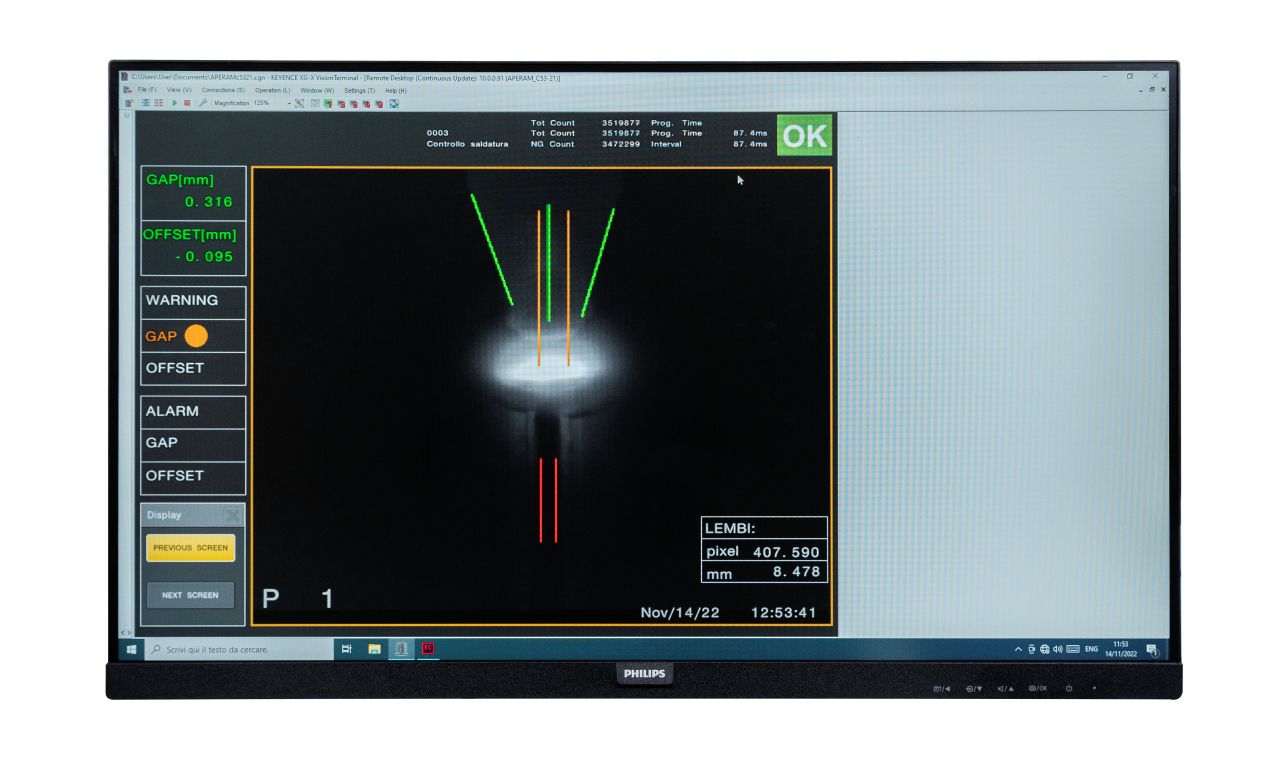

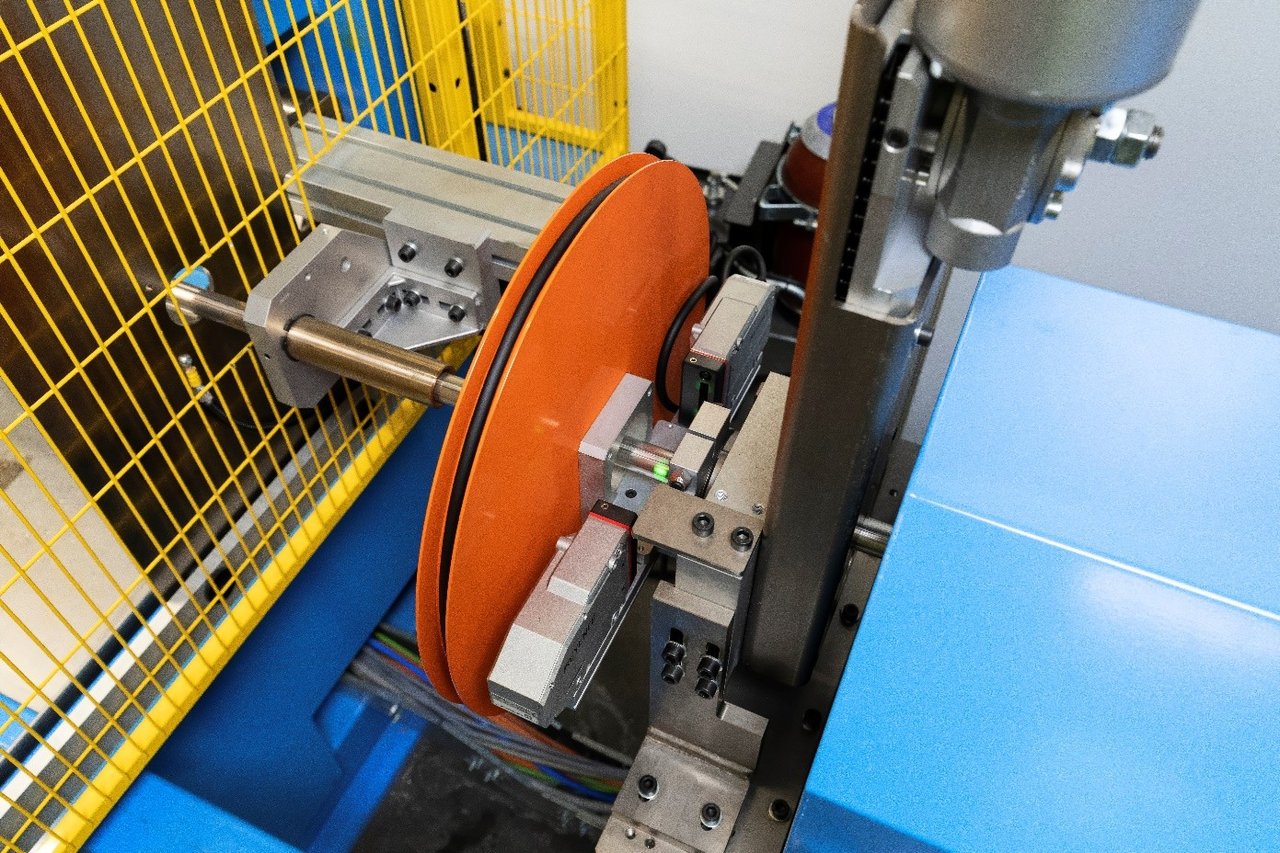

installed to continuously monitor the position of the strip edges and the wear of the electrode.

that eliminates oxidation, removing the need for further brushing or polishing.

Discover all the machine details

FLYING CUT-OFF UNIT

that, depending on the necessity, can be equipped with score and pull-apart system, circular saw cutting system, cutting die system or with interchangeable cutting system.

STRIP JOINING BENCH

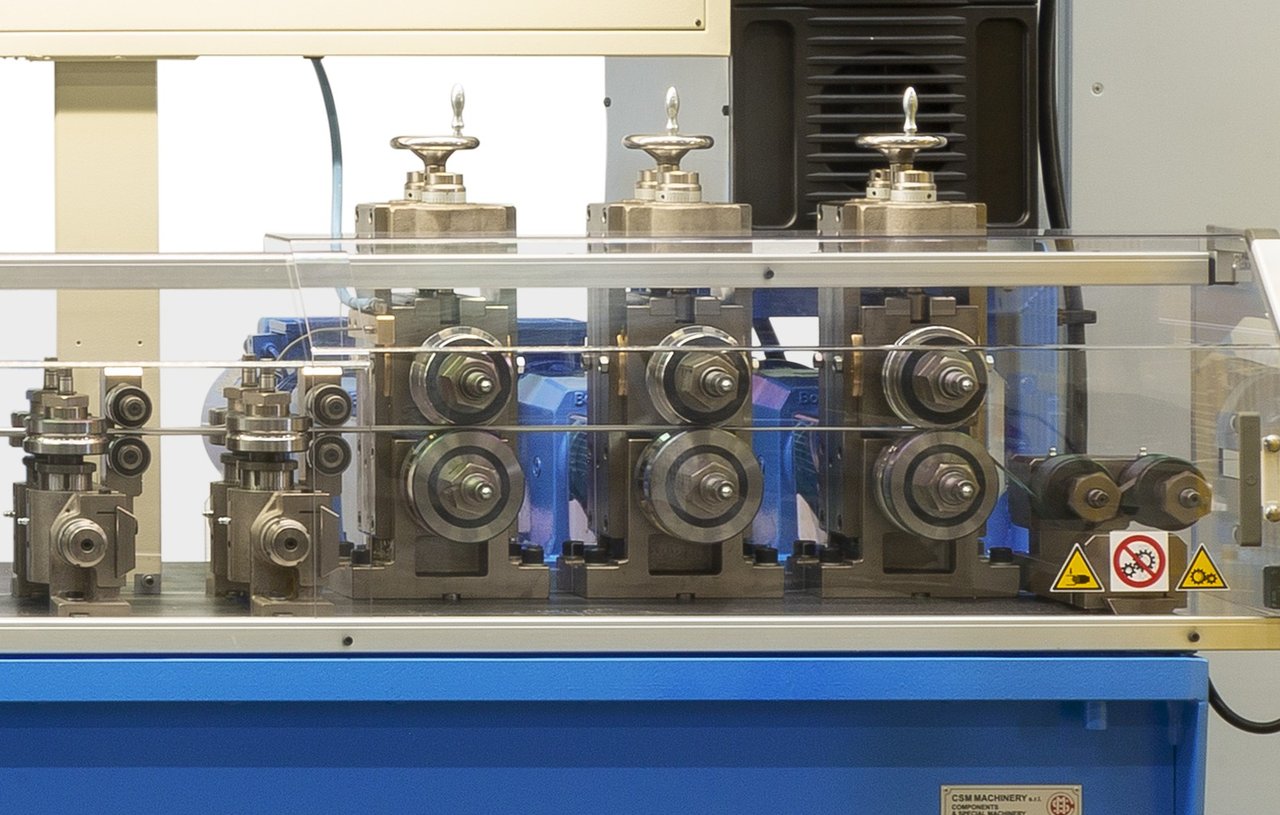

TUBE FORMING AND WELDING UNIT

with a smart camera to detect the welding arc.

OFF-LOADING UNIT

for tube in bars that can rotate to one side to off-load the good pieces or to the other side to unload any rejects.

STRAIGHTENING UNIT complete with 3 or 5 pairs of motorised rolls that force the tube to rotate on itself and with position indicators which allow the alteration of the interaxis of each roll pair to accommodate different tube diameters.

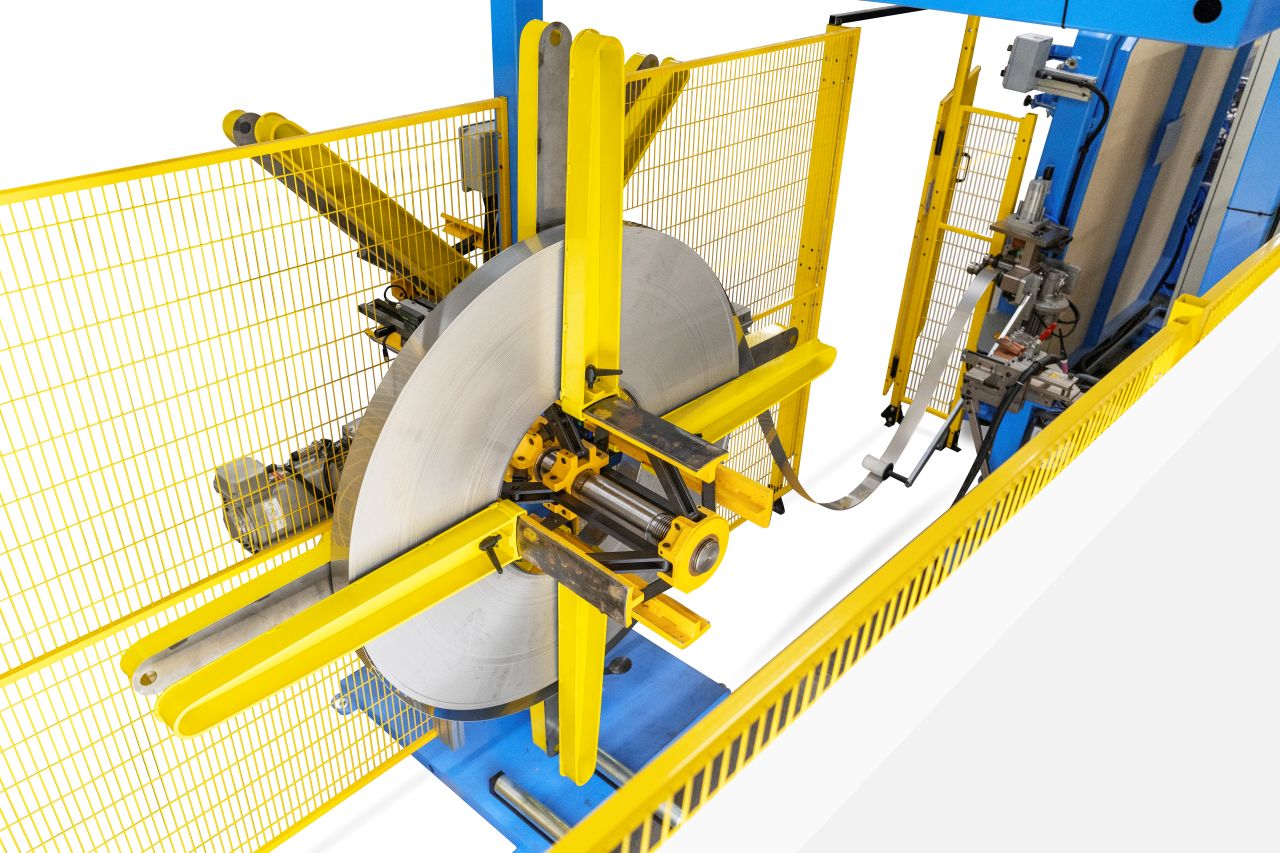

DOUBLE STRIP DE-REELER

unit with the possibility to hold no.2 stainless-steel strip coils, to avoid stopping the machine for changing the coil.

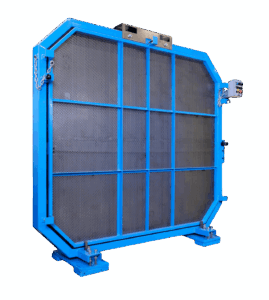

Vertical strip accumulation system for seamless production. This equipment allows to eliminate totally the line stops due to coil change.

The pneumatic heavy duty strip cutter is a pneumatic device that can be integrated in line and is recommended for the production of large diameter and thickness tube.

An automatic unit featuring a pilgrim step system and transfer rollers calibrate the ends of the cut tube using the guillotine cutting system. Two hydraulic punching units reduce the internal diameter at the ends, improving geometric uniformity and compatibility with processes like bending or finning.

Unit to deburr the ends of the cut tube by brushing. A set of rotating brushes removes the small burrs created during the cutting with a rotating blade, leaving a square cut at the ends without burrs.

Device for the inline tube diameter measuring, complete with CCD beam sensor, link interface (DP), fixing flange and adjustment parts.

Unit to test the weld quality of stainless-steel tubes, complete for one tube diameter, with support bench, complete with drawers, oil-air hydraulic press, complete with punch to enlarge the tube section (60°), clamp to hold the tube sample and pressure regulator, circular saw for the cutting to length of the sample to be tested and unit for the tube inside/outside deburring.

Designed for destructive and pressure holding tests, this station uses hydraulic deformation to test the mechanical resistance of cut-to-length tubes. It features a solid support bench, a cutting die holding unit, a tube deformation holding matrix, connection units between matrix and tube section and an hydraulic power unit with high pressure group (1000 bar) with proportional regulation.

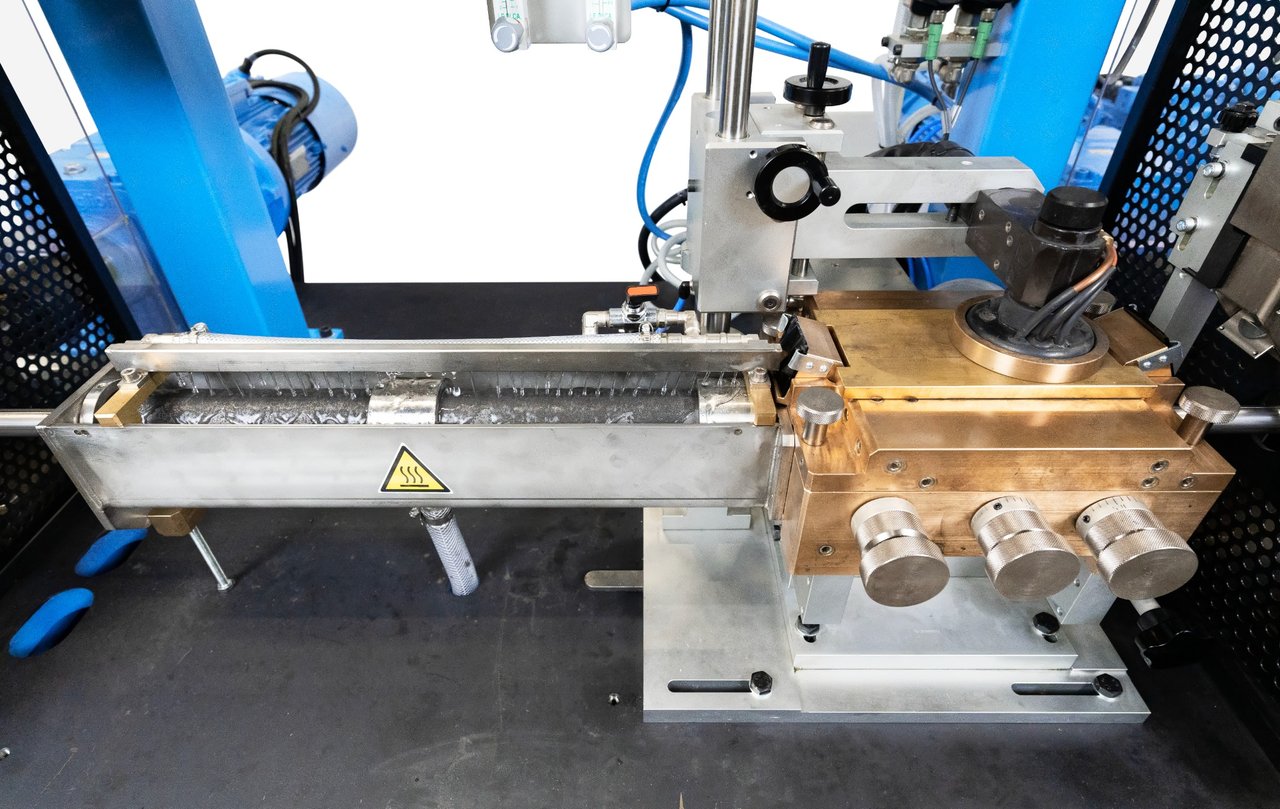

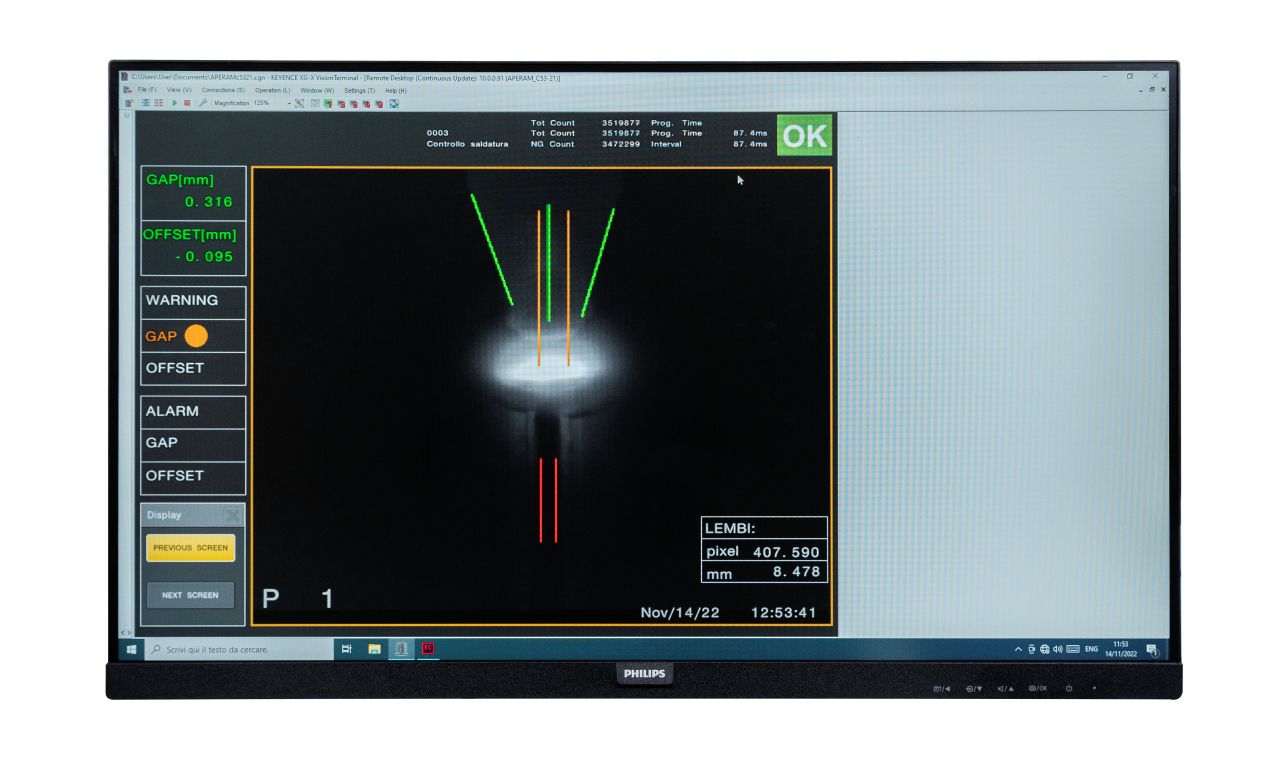

The device uses a special camera with adjustable optics to detect the welding arc (plasm). The camera is pointed inside our welding box which has an opening on the cover. The camera is capable to detect also the edge of the strip to be welded. An electronic device processes images from the camera and calculates the theoretical axis. This axis should be in the middle of the edges. The electronic device compares strip edge position and two threshold values related to electrode axis. The system generates two digital alarm signals. It is possible to adjust all the settings and to visualize the images through a normal web browser. The system is provided complete with: camera, optics for camera (75mm), camera micro-controller unit, micro-controller unit power pack, mechanical support frame for camera, LCD 17” monitor, monitor support and connection cables.

Vertical strip accumulation system for seamless production. This equipment allows to eliminate totally the line stops due to coil change.

The pneumatic heavy duty strip cutter is a pneumatic device that can be integrated in line and is recommended for the production of large diameter and thickness tube.

An automatic unit featuring a pilgrim step system and transfer rollers calibrate the ends of the cut tube using the guillotine cutting system. Two hydraulic punching units reduce the internal diameter at the ends, improving geometric uniformity and compatibility with processes like bending or finning.

Unit to deburr the ends of the cut tube by brushing. A set of rotating brushes removes the small burrs created during the cutting with a rotating blade, leaving a square cut at the ends without burrs.

Device for the inline tube diameter measuring, complete with CCD beam sensor, link interface (DP), fixing flange and adjustment parts.

Unit to test the weld quality of stainless-steel tubes, complete for one tube diameter, with support bench, complete with drawers, oil-air hydraulic press, complete with punch to enlarge the tube section (60°), clamp to hold the tube sample and pressure regulator, circular saw for the cutting to length of the sample to be tested and unit for the tube inside/outside deburring.

Designed for destructive and pressure holding tests, this station uses hydraulic deformation to test the mechanical resistance of cut-to-length tubes. It features a solid support bench, a cutting die holding unit, a tube deformation holding matrix, connection units between matrix and tube section and an hydraulic power unit with high pressure group (1000 bar) with proportional regulation.

The device uses a special camera with adjustable optics to detect the welding arc (plasm). The camera is pointed inside our welding box which has an opening on the cover. The camera is capable to detect also the edge of the strip to be welded. An electronic device processes images from the camera and calculates the theoretical axis. This axis should be in the middle of the edges. The electronic device compares strip edge position and two threshold values related to electrode axis. The system generates two digital alarm signals. It is possible to adjust all the settings and to visualize the images through a normal web browser. The system is provided complete with: camera, optics for camera (75mm), camera micro-controller unit, micro-controller unit power pack, mechanical support frame for camera, LCD 17” monitor, monitor support and connection cables.

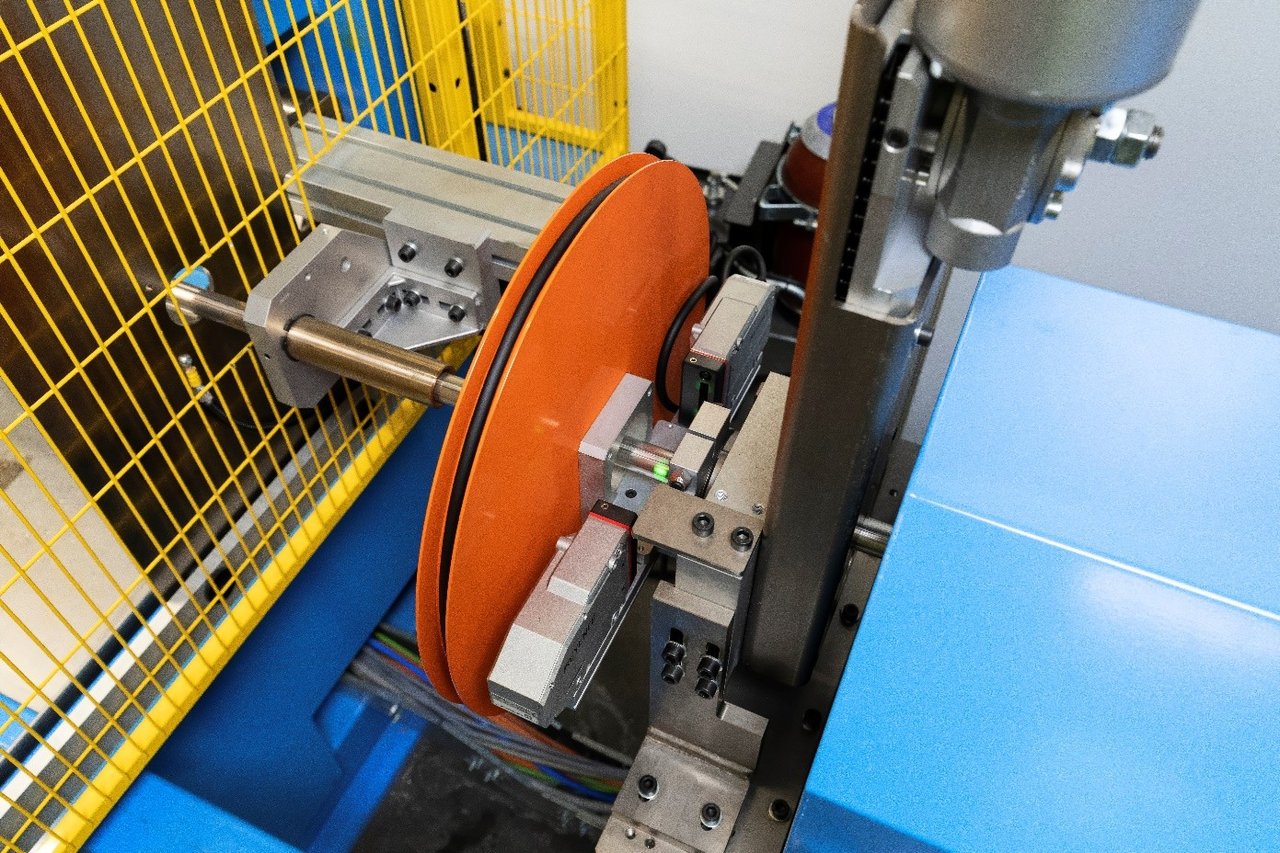

CSM MACHINERY integrates a reshaping unit into its stainless steel tube production lines, enabling the creation of non-round tube profiles and designing alternative shapes based on manufacturers’ needs.

Tube outer diameter min–max | STANDARD 6–16 mm | OVERSIZE 10–28 mm |

Tube wall thickness min–max | STANDARD 0.4–1 mm | OVERSIZE 0.4–1.5 mm |

Max. tube length | mm to be defined |

Length tolerance from 300 to 3000 mm | ± 1 mm |

Length tolerance from 3001 to 4300 mm | ± 1,5 mm |

Length tolerance from 4301 to 6000 mm | ± 5 mm |

Length tolerance from 6001 to 10000 mm | ± 10 mm |

Length tolerance from 10001 to 14000 mm | ± 15 mm |

Tube outer diameter tolerance UNI EN 10217-7 OD 6–10 mm | ± 0,075 mm |

Tube outer diameter tolerance UNI EN 10217-7 OD 10.1–15 | ± 0,080 mm |

Tube outer diameter tolerance UNI EN 10217-7 OD 15.1–25 mm | ± 0,100 mm |

ALLOYS | • AISI 304 (EN 1.4301) • AISI 304L (EN 1.4307) • AISI 321 (EN 1.4541) • AISI 316L (EN 1.4404) • AISI 444 (EN 1.4521) • AISI 316S (EN 1.4435) • AISI 316Ti (EN 1.4571) • AISI 310S (EN 1.4845) • AISI 309 (EN 1.4828) • ALLOY 800 (EN 1.4876) • ALLOY 840 (EN 1.4847) • ALLOY 825 (EN 2.4858) • ALLOY 600 (EN 2.4816) • ALLOY 601 (EN 2.4851) |

Discover the other products in our range