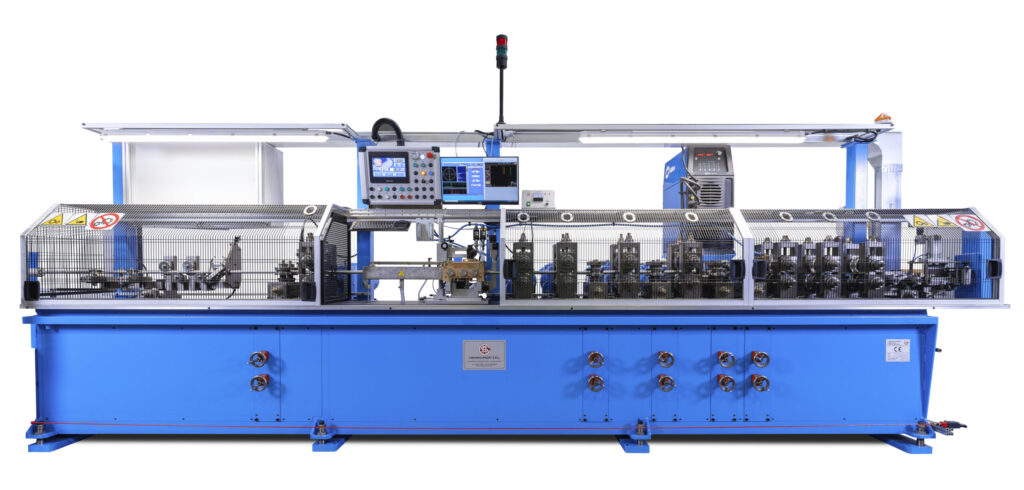

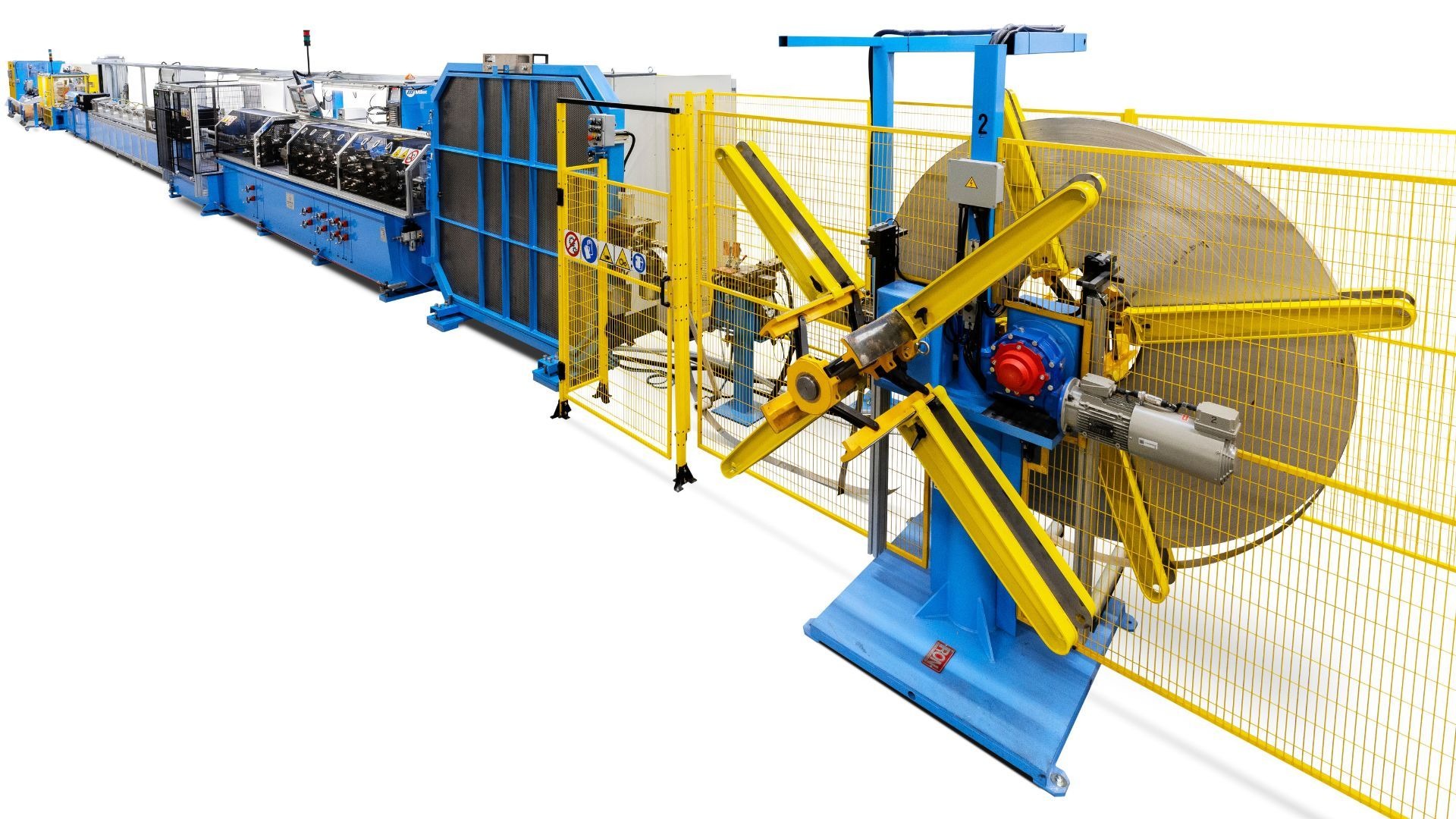

CSM MACHINERY employs a TIG-welded tube forming and production line with an in-line bright annealing process to fabricate tubes in both bars and coils.

This forming and welding line is available in two versions: the standard one for tubes with the external diameter ranging from 6 to 16 mm and the heavy duty version for tubes with diameter ranging from 10 to 28 mm.

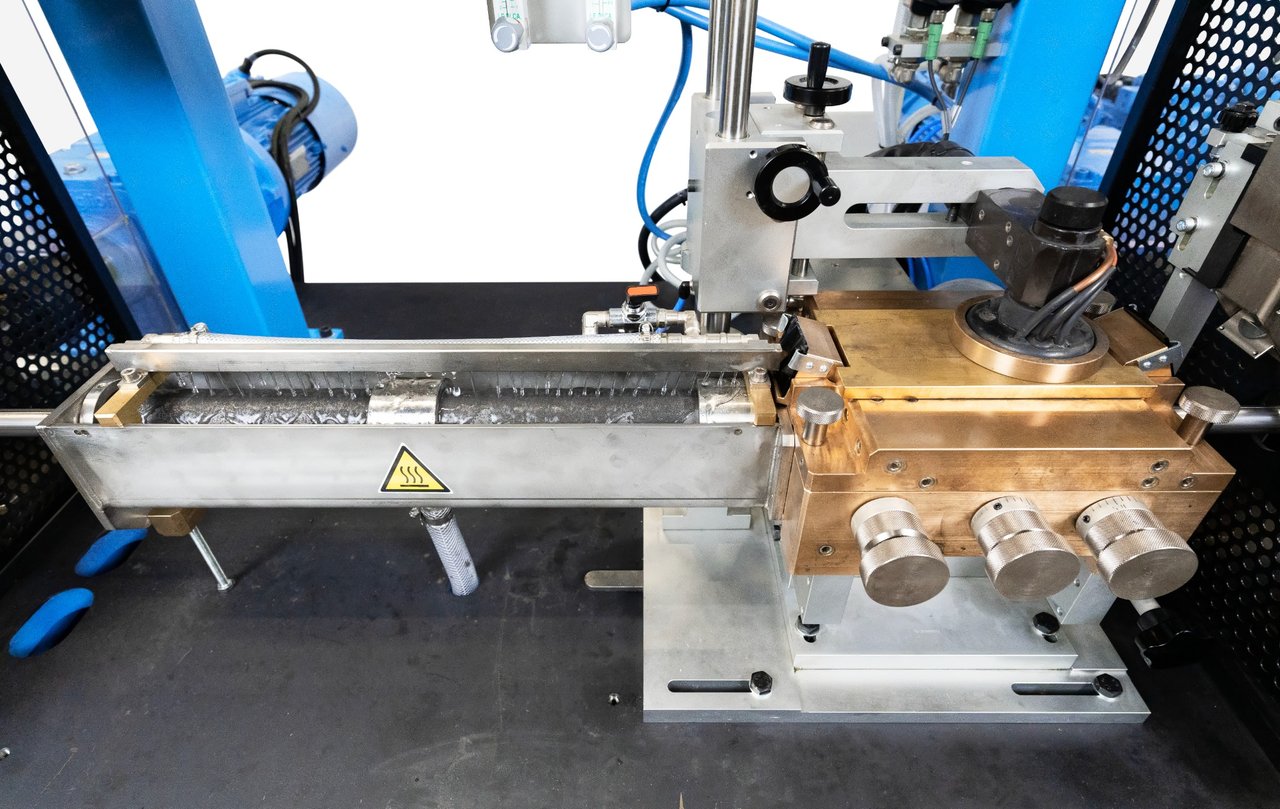

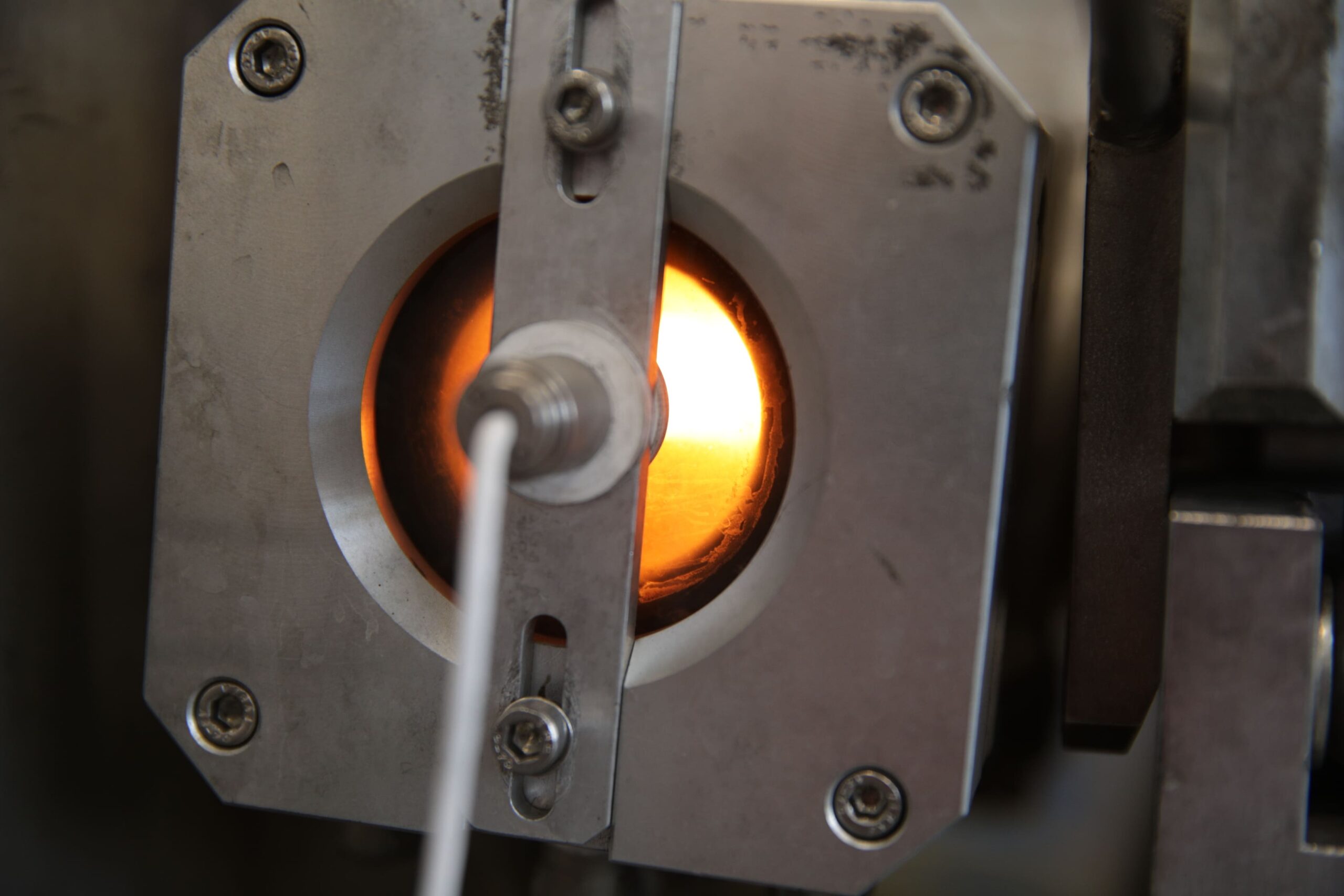

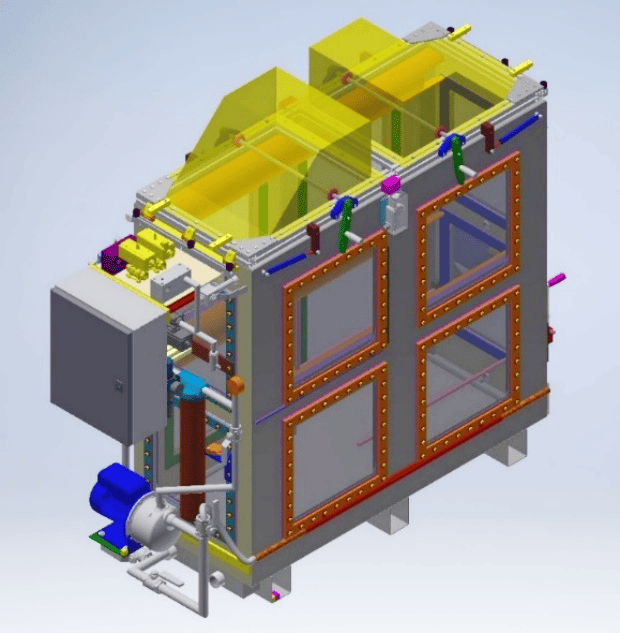

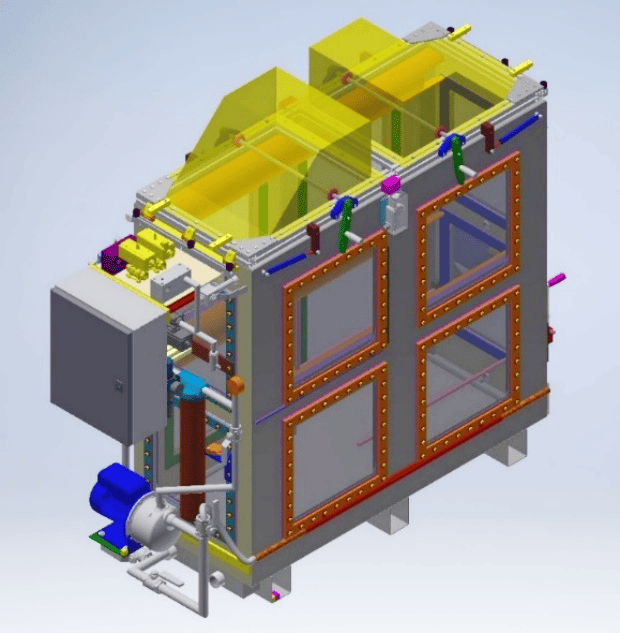

The annealed stainless steel production lines are supplied with induction coils and power units up to 150 kW, as well as optical pyrometers to check the annealing temperature and cooling tunnels while under an inert atmosphere. The inert atmosphere guarantees a high quality of the weld, allowing for homogeneity and brightness of the tube after heat treatment.

The machine has a quick set-up thanks to the possibility to recall stored parameters depending on the type of product being produced. This line gives the possibility to produce welded tubes, just by stopping the annealing section.

The concrete advantages that make the difference

ensure high production capacity.

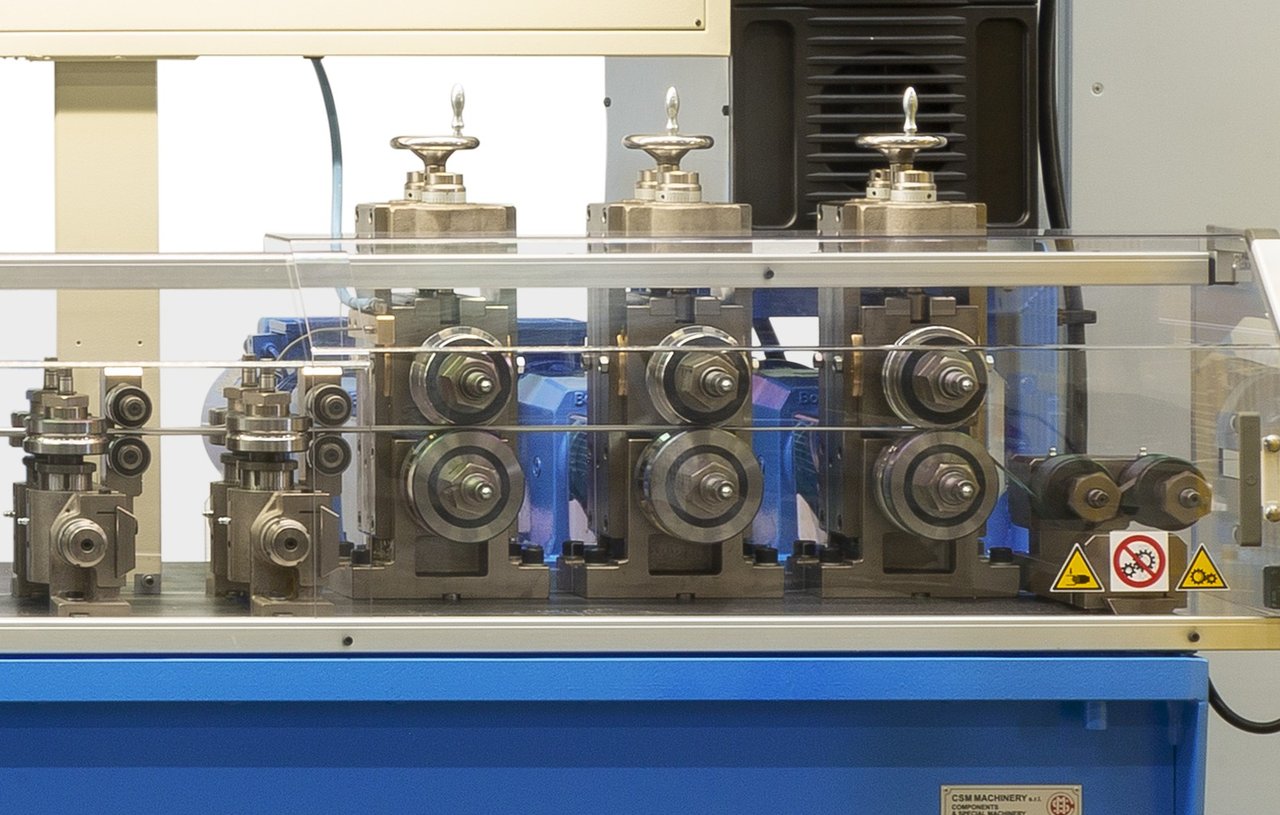

for each motorized forming head for maximum flexibility.

ensure clean final products, with no oxidation.

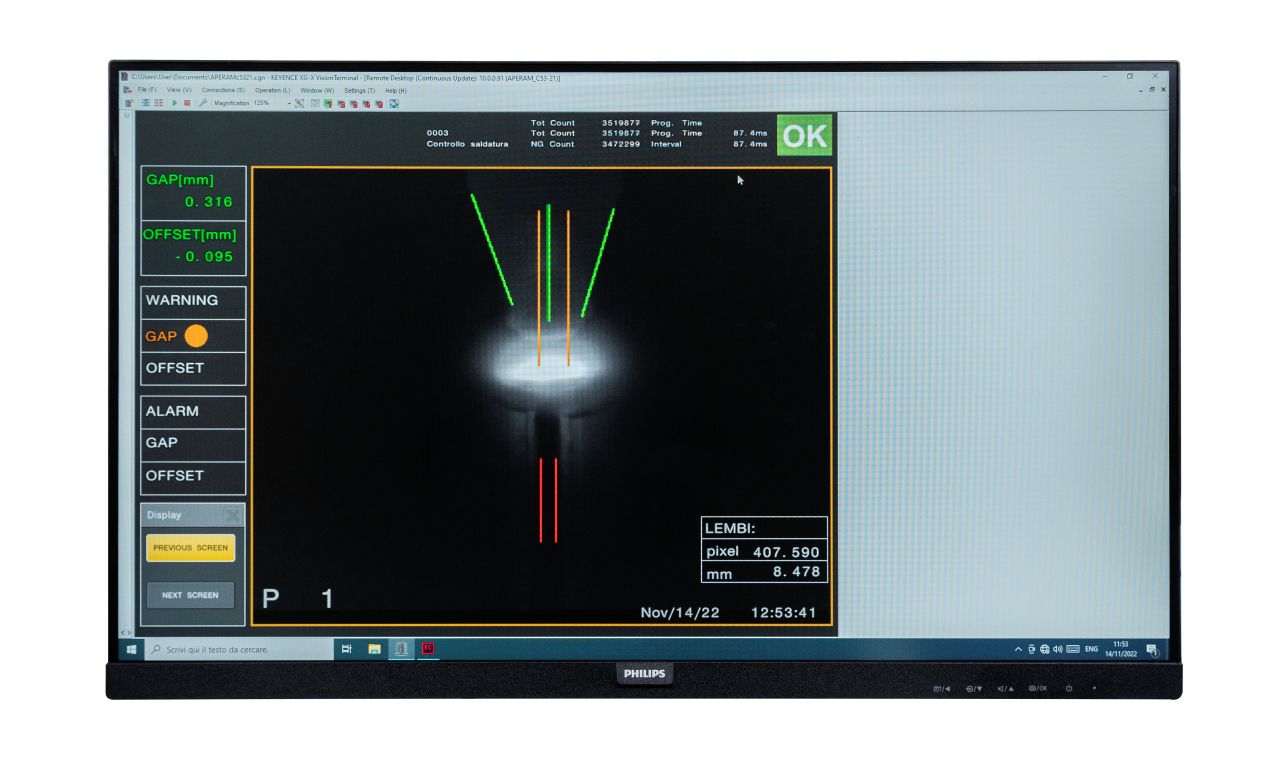

installed to continuously monitor the position of the strip edges and the wear of the electrode.

meant as elongation and “brightness” of the tube after heat treatment.

either “as welded” or “heat-treated”.

Discover all the machine details

UNITÀ DI SCARICO per tubo in barre con bandella rotante che rovescia da una parte i pezzi buoni e dall’altra gli eventuali scarti.

UNITÀ DI TAGLIO AL VOLO con sistema a incisione e strappo, sistema a sega circolare oppure con sistema di taglio interscambiabile.

UNITÀ DI RADDRIZZATURA per la correzione delle eventuali deformazioni prodotte durante la ricottura.

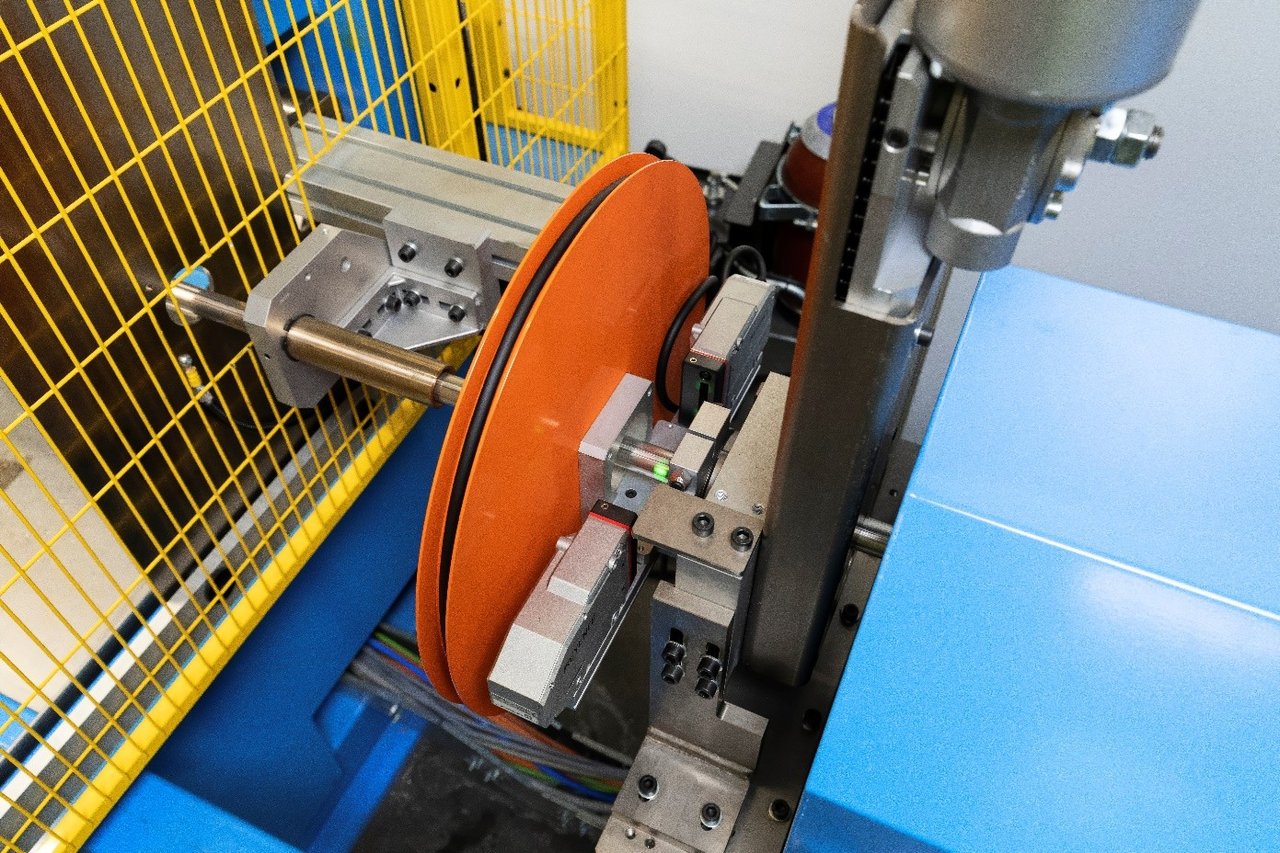

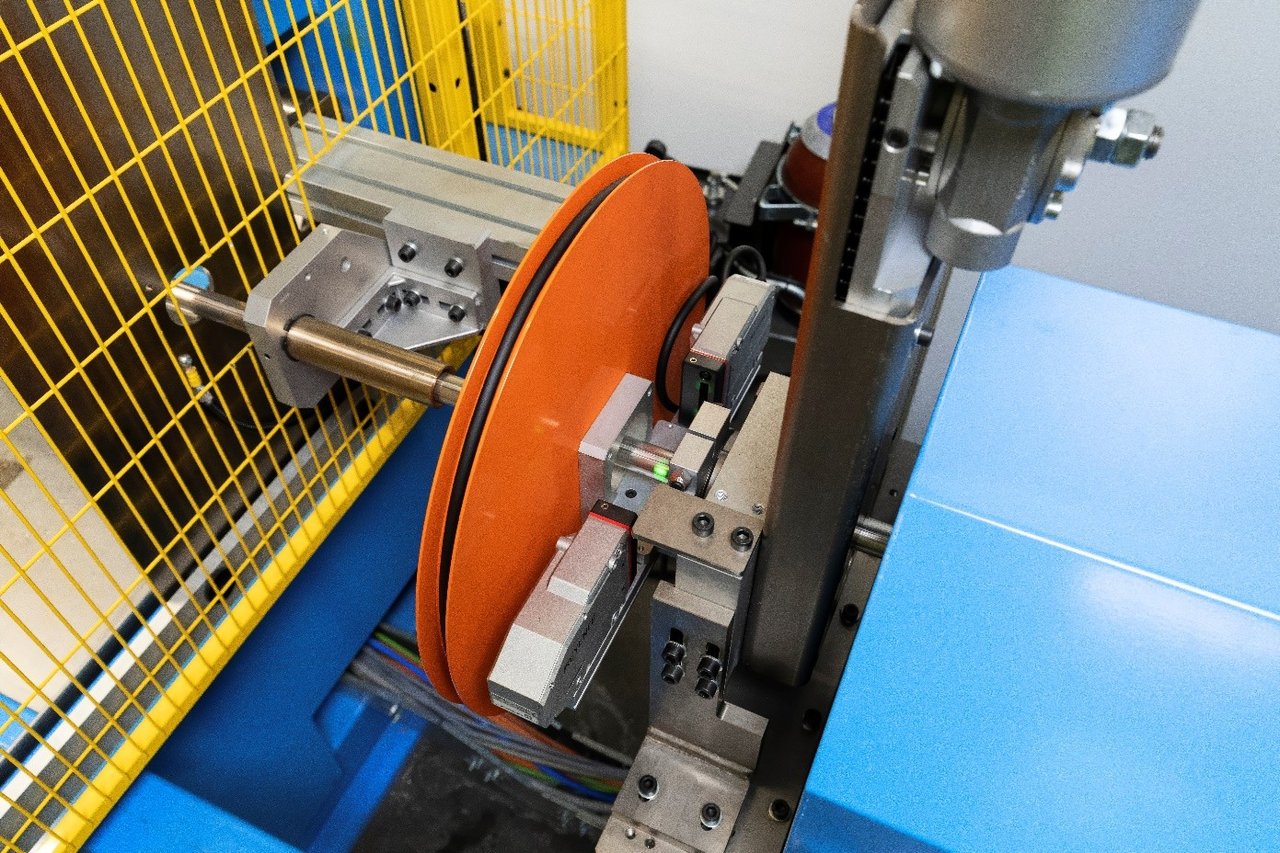

UNITÀ DI FORMATURA E SALDATURA con videocamera per il monitoraggio dell’arco di saldatura.

UNITÀ DI RICOTTURA con forno a induzione e canale di raffreddamento con circolazione dell’acqua.

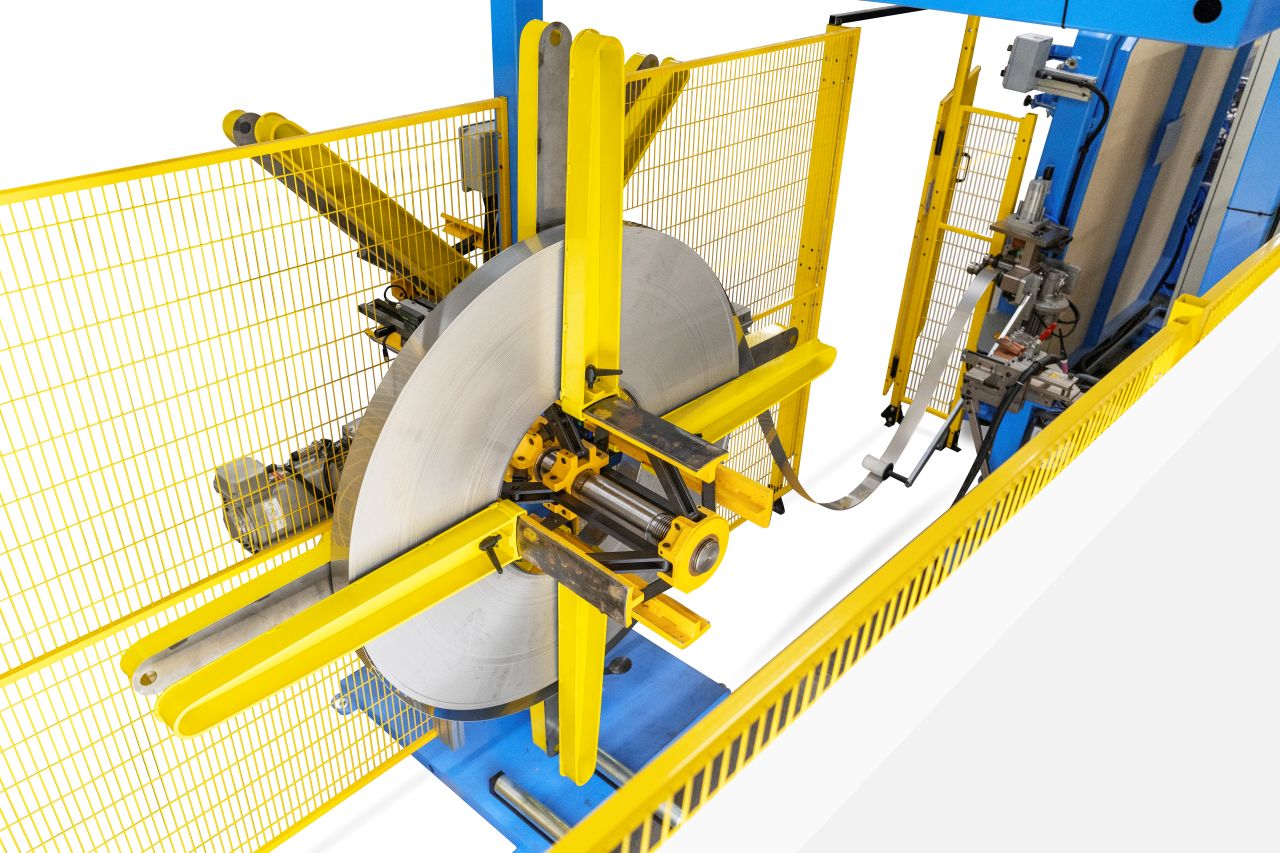

ACCUMULATORE VERTICALE PER NASTRO che favorisce una produzione senza interruzioni.

BANCO DI GIUNZIONE NASTRO

DOPPIO ASPO SVOLGITORE con la possibilità di contenere 2 bobine di nastro in acciaio inossidabile, che evita di fermare la macchina durante la sostituzione della bobina, minimizzando i tempi inattivi.

The pneumatic heavy duty strip cutter is a pneumatic device that can be integrated in line and is recommended for the production of large diameter and thickness tubes.

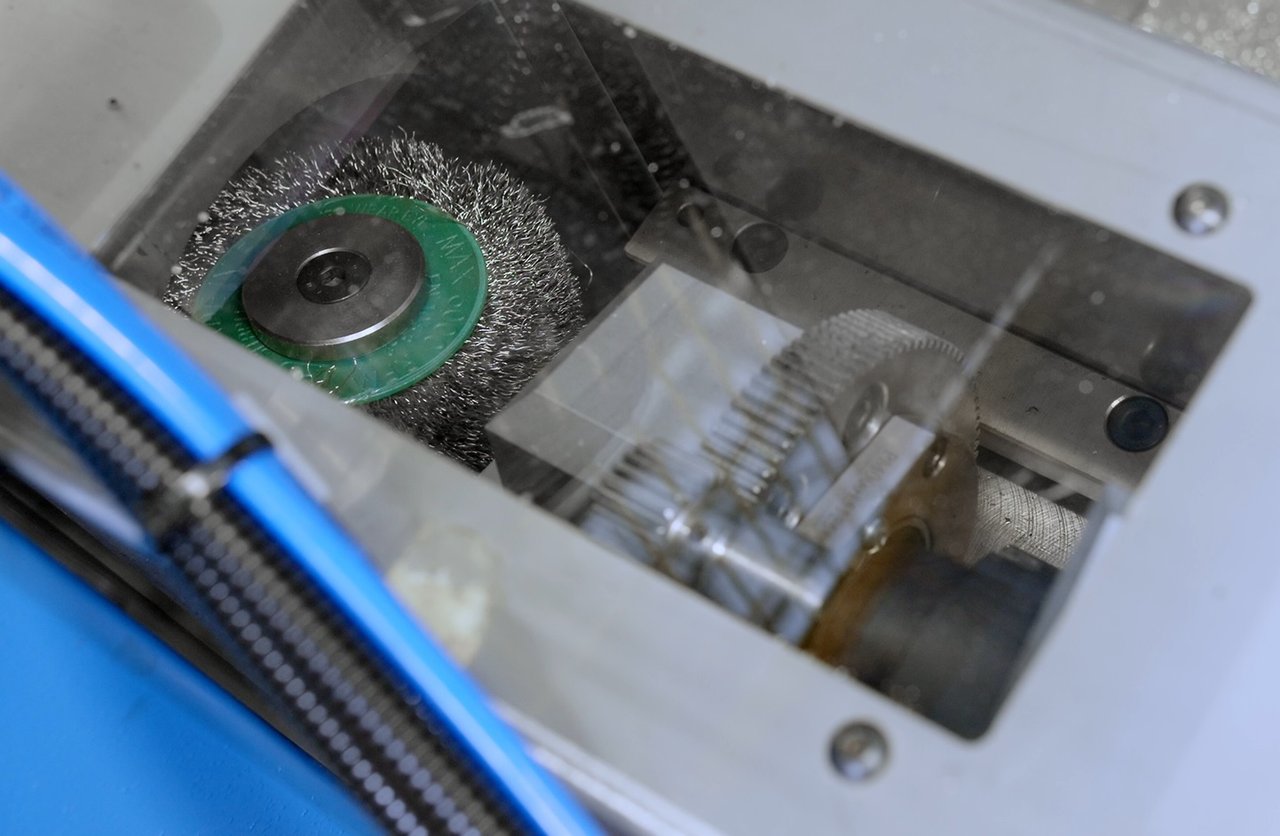

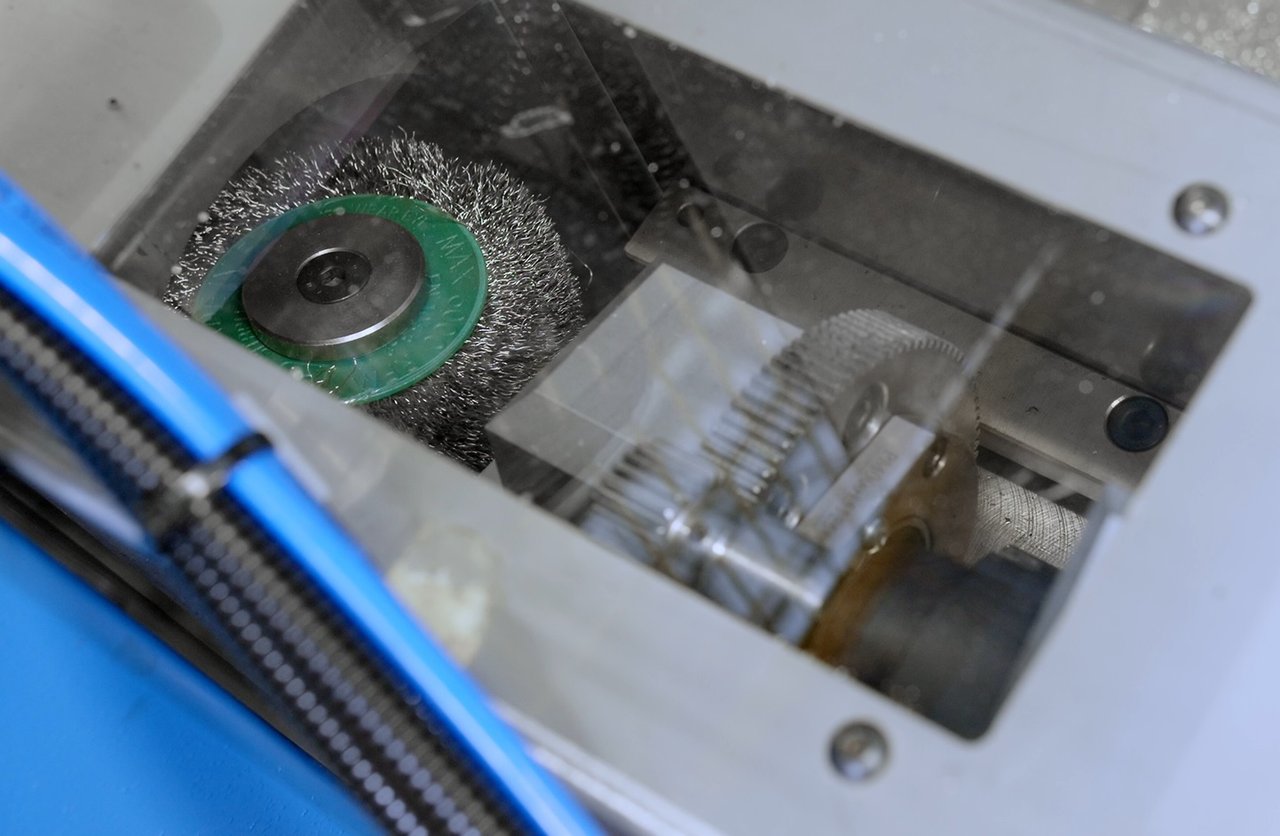

Unit to deburr the ends of the cut tube by brushing. A set of rotating brushes removes the small burrs created during the cutting with a rotating blade, leaving a square cut at the ends without burrs.

Device for the inline tube diameter measuring, complete with CCD beam sensor, link interface (DP), fixing flange and adjustment parts.

Device made to recoil annealed stainless steel tube. This device is designed to be put in line with the tube mills with annealing, so that the tube being welded can be recoiled in ordered layers. The tube is laid from right to left by a controlled arm. The tightness and ordered layering are ensured by setting the appropriate torque and speed for a particular tube being produced on the machine. The recoilers have two coiling drums so that the machine does not have to stop each time a coil is finished. Once a coil is complete, the operator moves the tube end onto the other coiling drum, and once the recoiling starts, the attention can be focused on the other, to tighten it with cable ties and remove it from the drum.

Unit to test the weld quality of stainless-steel tubes, complete for one tube diameter, with support bench, complete with drawers, oil-air hydraulic press, complete with punch to enlarge the tube section (60°), clamp to hold the tube sample and pressure regulator, circular saw for the cutting to length of the sample to be tested and unit for the tube inside/outside deburring.

Unit to test tube in coils under water, utilizing pressure up to 60 bar, complete with: hydraulic and pneumatic circuitry for feeding, discharging and filtering of water, vertical test tank and electropneumatic safety system to manage load and unload pressure.

Designed for destructive and pressure holding tests, this station uses hydraulic deformation to test the mechanical resistance of cut-to-length tubes. It features a solid support bench, a cutting die holding unit, a tube deformation holding matrix, connection units between the matrix and tube section, and a hydraulic power unit with high high-pressure group (1000 bar) with proportional regulation.

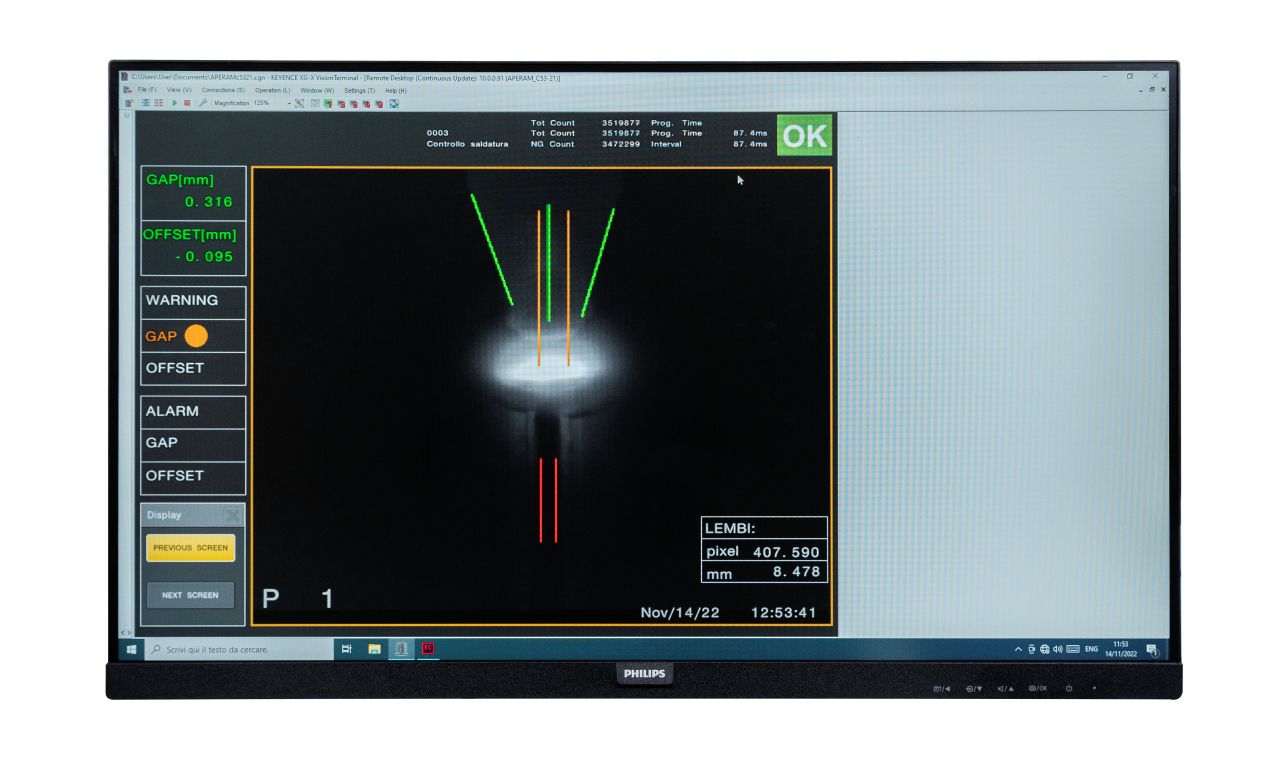

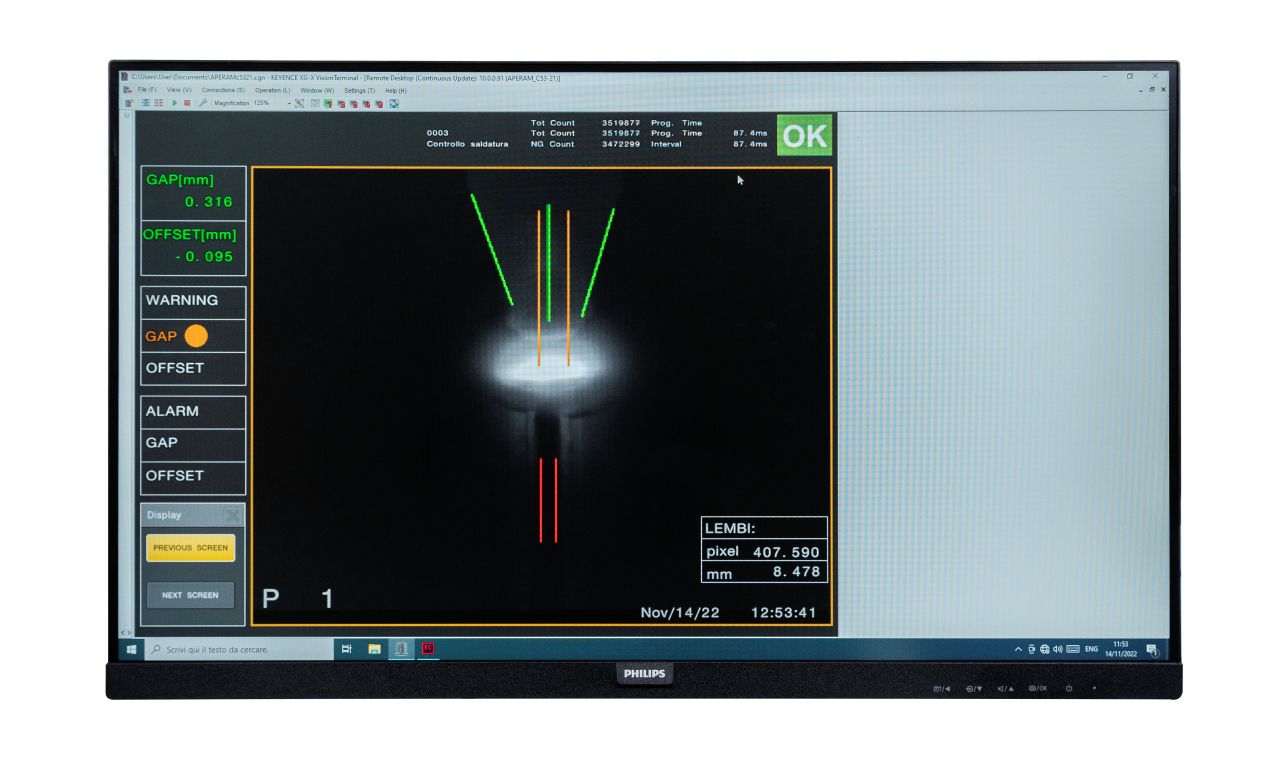

The device uses a special camera with adjustable optics to detect the welding arc (plasm). The camera is pointed inside our welding box which has an opening on the cover. The camera is capable to detect also the edge of the strip to be welded. An electronic device processes images from the camera and calculates the theoretical axis. This axis should be in the middle of the edges. The electronic device compares strip edge position and two threshold values related to electrode axis. The system generates two digital alarm signals. It is possible to adjust all the settings and to visualize the images through a normal web browser. The system is provided complete with: camera, optics for camera (75mm), camera micro-controller unit, micro-controller unit power pack, mechanical support frame for camera, LCD 17” monitor, monitor support and connection cables.

The pneumatic heavy duty strip cutter is a pneumatic device that can be integrated in line and is recommended for the production of large diameter and thickness tubes.

Unit to deburr the ends of the cut tube by brushing. A set of rotating brushes removes the small burrs created during the cutting with a rotating blade, leaving a square cut at the ends without burrs.

Device for the inline tube diameter measuring, complete with CCD beam sensor, link interface (DP), fixing flange and adjustment parts.

Device made to recoil annealed stainless steel tube. This device is designed to be put in line with the tube mills with annealing, so that the tube being welded can be recoiled in ordered layers. The tube is laid from right to left by a controlled arm. The tightness and ordered layering are ensured by setting the appropriate torque and speed for a particular tube being produced on the machine. The recoilers have two coiling drums so that the machine does not have to stop each time a coil is finished. Once a coil is complete, the operator moves the tube end onto the other coiling drum, and once the recoiling starts, the attention can be focused on the other, to tighten it with cable ties and remove it from the drum.

Unit to test the weld quality of stainless-steel tubes, complete for one tube diameter, with support bench, complete with drawers, oil-air hydraulic press, complete with punch to enlarge the tube section (60°), clamp to hold the tube sample and pressure regulator, circular saw for the cutting to length of the sample to be tested and unit for the tube inside/outside deburring.

Unit to test tube in coils under water, utilizing pressure up to 60 bar, complete with: hydraulic and pneumatic circuitry for feeding, discharging and filtering of water, vertical test tank and electropneumatic safety system to manage load and unload pressure.

Designed for destructive and pressure holding tests, this station uses hydraulic deformation to test the mechanical resistance of cut-to-length tubes. It features a solid support bench, a cutting die holding unit, a tube deformation holding matrix, connection units between the matrix and tube section, and a hydraulic power unit with high high-pressure group (1000 bar) with proportional regulation.

The device uses a special camera with adjustable optics to detect the welding arc (plasm). The camera is pointed inside our welding box which has an opening on the cover. The camera is capable to detect also the edge of the strip to be welded. An electronic device processes images from the camera and calculates the theoretical axis. This axis should be in the middle of the edges. The electronic device compares strip edge position and two threshold values related to electrode axis. The system generates two digital alarm signals. It is possible to adjust all the settings and to visualize the images through a normal web browser. The system is provided complete with: camera, optics for camera (75mm), camera micro-controller unit, micro-controller unit power pack, mechanical support frame for camera, LCD 17” monitor, monitor support and connection cables.

CSM MACHINERY integrates a reshaping unit into its stainless steel tube production lines, enabling the creation of non-round tube profiles and designing alternative shapes based on manufacturers’ needs.

PRODUCTION OF TUBES IN BARS – Tube outer diameter min–max | STANDARD 6 - 16 mm| OVERSIZE 10 - 28 mm |

PRODUCTION OF TUBES IN BARS – Tube wall thickness min–max (mm) | STANDARD 0,4 - 1 mm | OVERSIZEA 0,4 – 1,5 mm |

PRODUCTION OF TUBES IN BARS – Max. tube length | mm to be defined |

PRODUCTION OF TUBES IN BARS – Length tolerance from 300 to 3000 mm | ± 1 mm |

PRODUCTION OF TUBES IN BARS – Length tolerance from 3001 to 4300 mm | ± 1,5 mm |

PRODUCTION OF TUBES IN BARS – Length tolerance from 4301 to 6000 mm | ± 5 mm |

PRODUCTION OF TUBES IN BARS – Length tolerance from 6001 to 10000 mm | ± 10 mm |

PRODUCTION OF TUBES IN BARS – Length tolerance from 10001 to 14000 mm | ± 15 mm |

PRODUCTION OF TUBES IN BARS – Tube outer diameter tolerance UNI EN 10217-7 OD 6–10 mm | ± 0,075 mm |

PRODUCTION OF TUBES IN BARS – Tube outer diameter tolerance UNI EN 10217-7 OD 10.1–15 mm | ± 0,080 mm |

PRODUCTION OF TUBES IN BARS – Tube outer diameter tolerance UNI EN 10217-7 OD 15.1–25 mm | ± 0,100 mm |

PRODUCTION OF TUBES IN COILS – Max. length | da 100 a 400 m |

PRODUCTION OF TUBES IN COILS – Max. coil width | STANDARD 330 mm | OVERSIZE 400 mm |

PRODUCTION OF TUBES IN COILS – Min. coil inner diameter | STANDARD 600 mm | OVERSIZE 600 mm |

PRODUCTION OF TUBES IN COILS – Max. coil outer diameter | STANDARD 1200 mm | OVERSIZE 1500 mm |

ALLOYS | AISI 304 (EN 1.4301) • AISI 304L (EN 1.4307) • AISI 321 (EN 1.4541) • AISI 316L (EN 1.4404) • AISI 444 (EN 1.4521) • AISI 316S (EN 1.4435) • AISI 316Ti (EN 1.4571) • AISI 310S (EN 1.4845) • AISI 309 (EN 1.4828) • ALLOY 800 (EN 1.4876) • ALLOY 840 (EN 1.4847) • ALLOY 825 (EN 2.4858) • ALLOY 600 (EN 2.4816) • ALLOY 601 (EN 2.4851) |

Discover the other products in our range