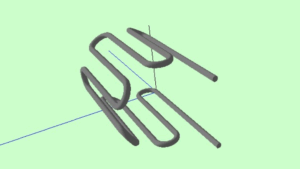

The numerically controlled universal bending machine, electronically programmable, with one or two bending units is capable of bending heating elements on one plane or on several planes in an automatic cycle in a great variety of shapes, sizes and bending angles.

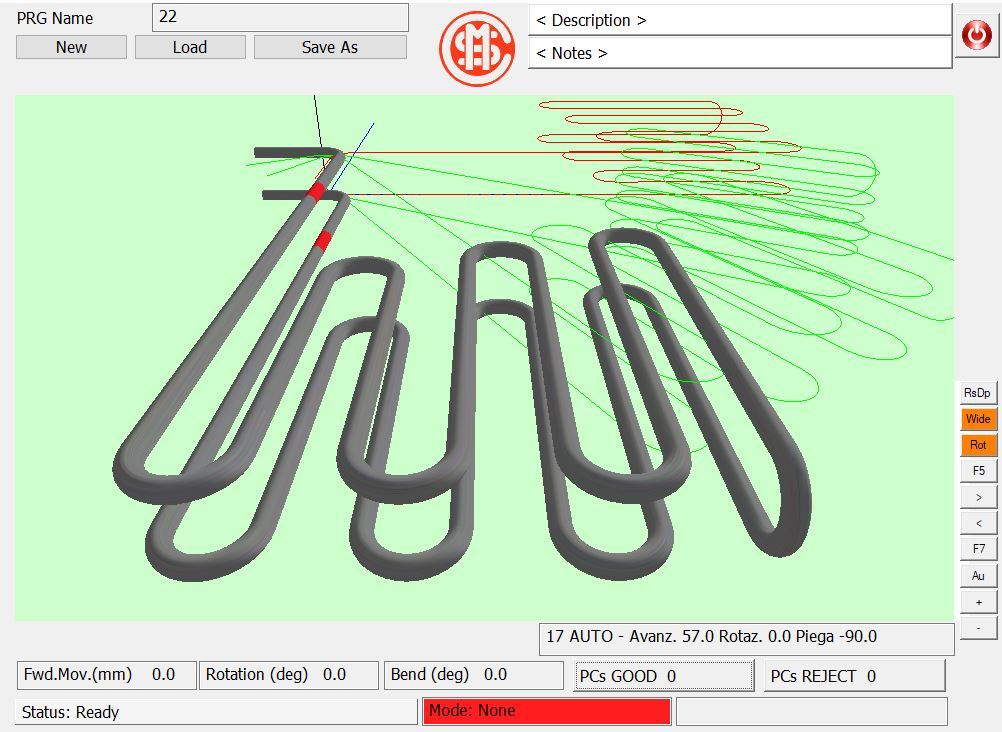

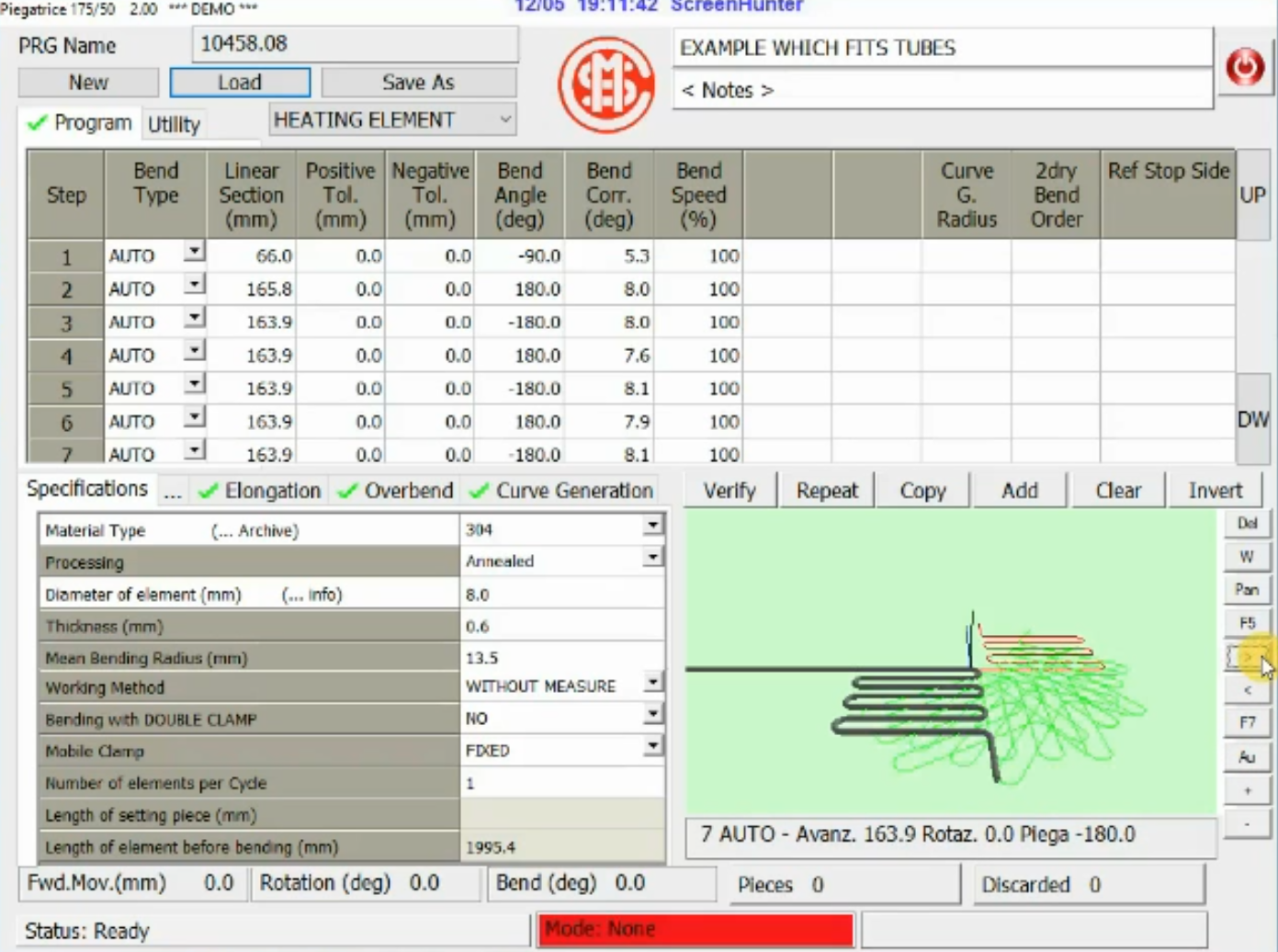

With the CSM universal bending machine, simply entering the standard bending data in the 3D-graphic programming software, the machine automatically generates the part program after searching for prior bending experience in its database. Recalling preset programs, the machine leads with dimensional tolerances right from the first element with a minimum setup time and a repeatable accuracy.

The concrete advantages that make the difference

which eliminates the need for manual adjustments.

allows you to create and immediately run the machine program simply by entering the geometric data of the heating element.

thanks to the reduced number of mechanical adjustments, eliminating the need for a specialist to control the machine.

thanks to a simplified design that reduces the need for routine maintenance and provides more consistent bending.

with the ability to program the machine quickly and easily.

including the option to program specific tolerances for each leg of the element.

Discover all the machine details

MAIN CABINET HOUSING COMPUTER

with touch screen monitor and keyboard, and the possibility to display the product in each bending step.

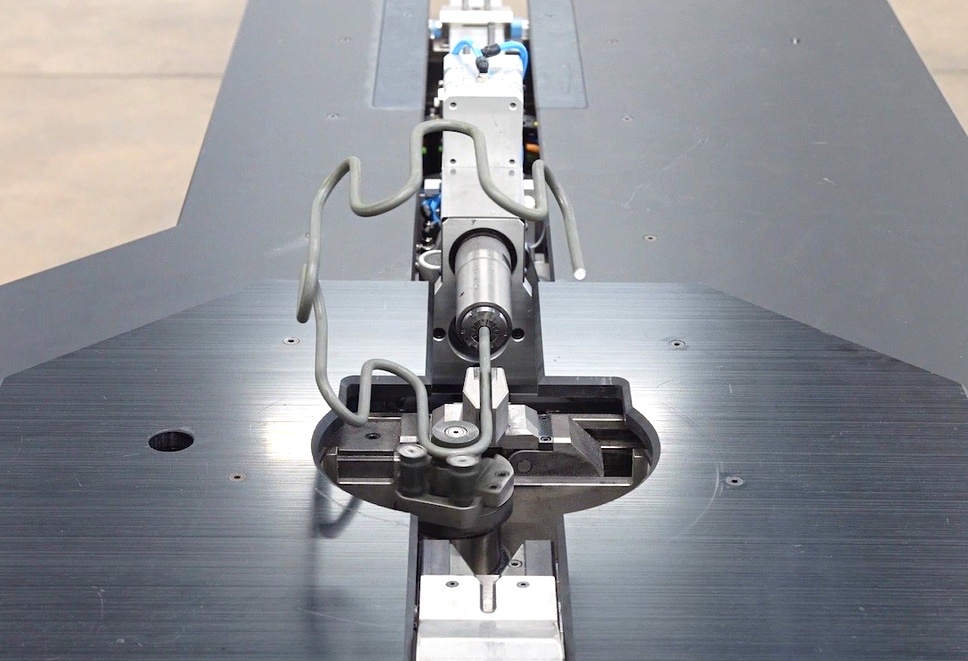

FRAME WITH A HORIZONTAL WORK SURFACE

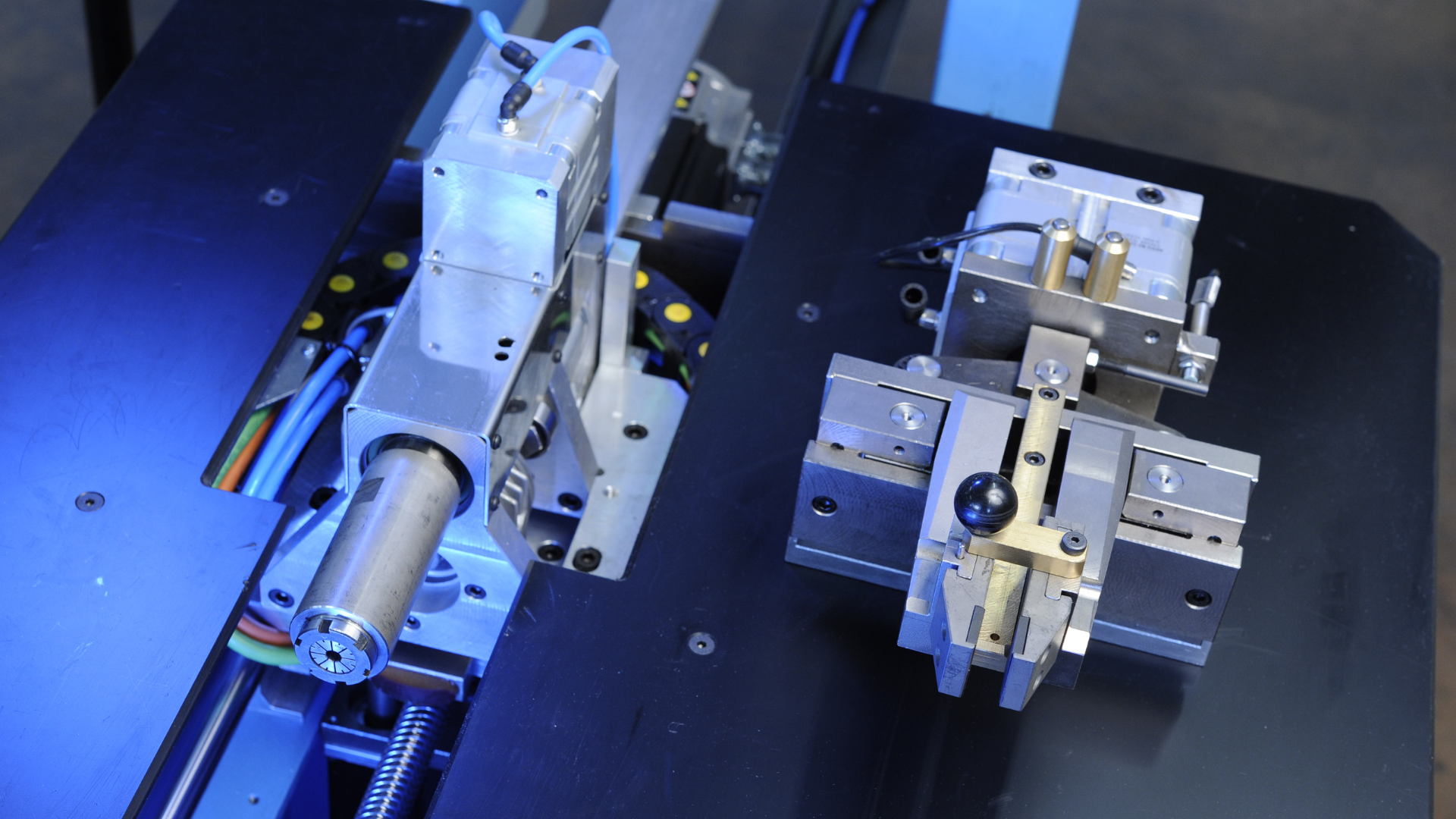

PNEUMATICALLY ACTIVATED MOBILE CLAMP

The mobile clamp is displaced by a brushless motor on an endless roller screw (1st numerically controlled axis).

PNEUMATICALLY ACTIVATED FIXED CLAMP

The clamp is used to grip the heating elements during the bending cycle.

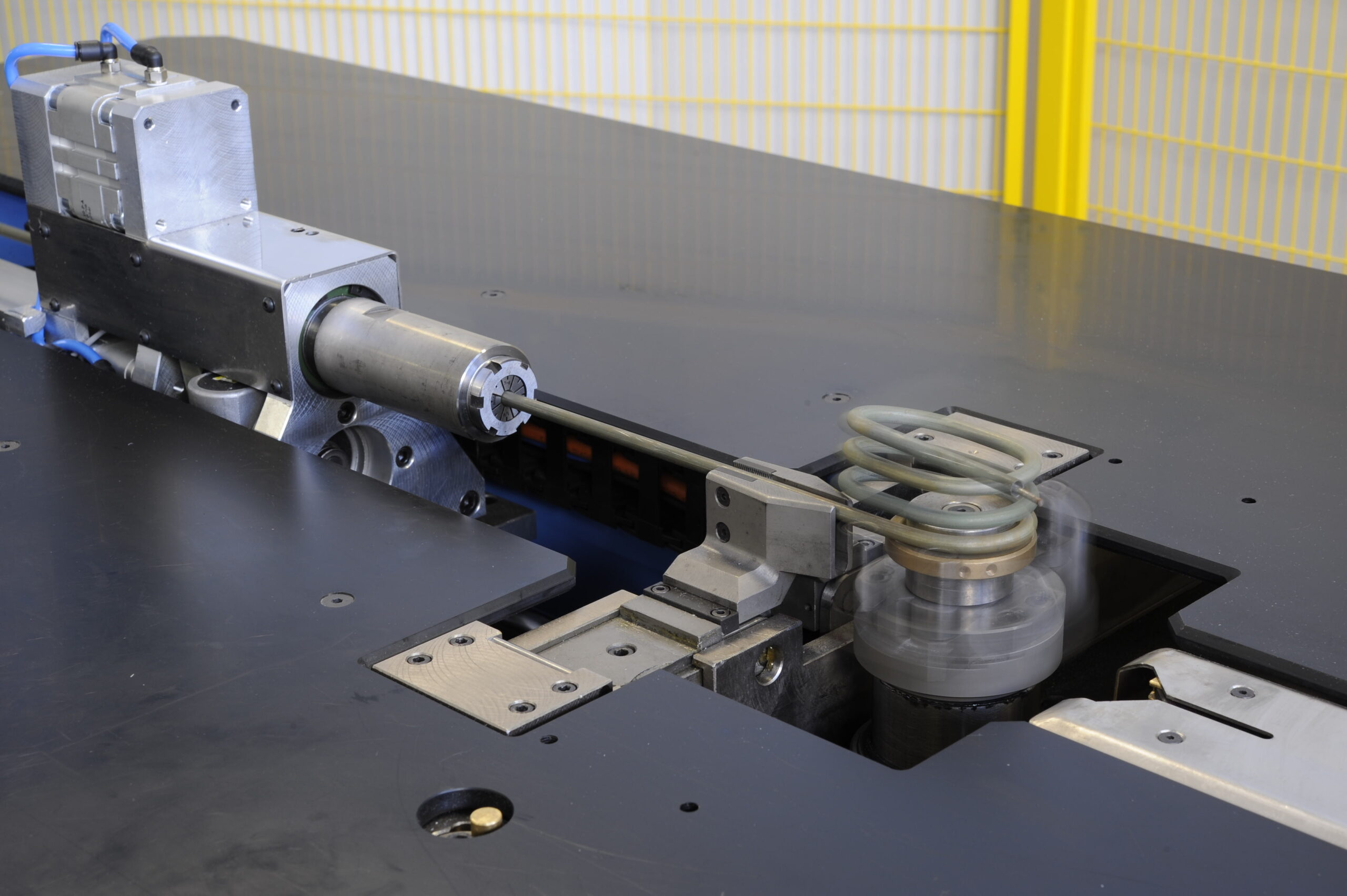

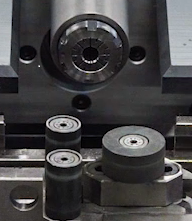

NUMERICALLY CONTROLLED BENDING UNIT

(2nd numerically controlled axis).

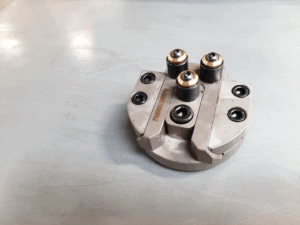

PNEUMATICALLY ACTIVATED MOBILE ROTATION CLAMP

(3nd controlled axis)

NOTE

The universal NC bending machine includes an electronic device for measuring the length of resistors and a dedicated safety PLC.

The rotating clamp offers the possibility to produce 3D (multiplane) elements in automatic mode (for elements with a diameter up to 12 mm The clamp is supplied with a bending roll for 3D elements with OD=18 mm and a clamp for a diameter (to be defined).

It offers the possibility to delimit a programmable work area and launch the bending cycle without two-hand control.

A wide range of extensions from 1000 to 6000 mm to be added to the base model.

065.08.146-00: Bending roll (for standard head). PM00001555*0: Bending roll for 3D elements (for standard head with rotating clamp). P3967*0: Bending roll for Heavy Duty head. PM00001371*0: Clamp for rotating unit (in addition to the clamp supplied with the machine).

Bending head for small radii, adjustable, for bending machine mod. 170/50 e 171/50 (bending roll diameter range 12 ÷ 17 mm). Max element outer diameter: Ø8,5 mm.

to allow for saving and backup of the bending programs.

The rotating clamp offers the possibility to produce 3D (multiplane) elements in automatic mode (for elements with a diameter up to 12 mm The clamp is supplied with a bending roll for 3D elements with OD=18 mm and a clamp for a diameter (to be defined).

It offers the possibility to delimit a programmable work area and launch the bending cycle without two-hand control.

A wide range of extensions from 1000 to 6000 mm to be added to the base model.

065.08.146-00: Bending roll (for standard head). PM00001555*0: Bending roll for 3D elements (for standard head with rotating clamp). P3967*0: Bending roll for Heavy Duty head. PM00001371*0: Clamp for rotating unit (in addition to the clamp supplied with the machine).

Bending head for small radii, adjustable, for bending machine mod. 170/50 e 171/50 (bending roll diameter range 12 ÷ 17 mm). Max element outer diameter: Ø8,5 mm.

to allow for saving and backup of the bending programs.

Lead with dimensional tolerances right from the first heating element.

Range of diameters of heat treated heating elements mod 170/50 | 6,3– 12,5 mm |

Range of diameters of heat treated heating elements mod 171/50 | 6,3– 16,0 mm |

Tolerance on the diameter (when bending two or more elements at a time) | ±0,06 mm |

Maximum difference in length of the heating elements | 180 mm |

Elements per cycle with measurement | 1 pc |

Elements per cycle without measurement | |

Elements per cycle with diameter 6,30-6,50 mm | 4 pc |

Elements per cycle with diameter 8,00-8,50 mm | 2 pc |

Elements per cycle with diameter > mm 8,50 | 1 pc |

Minimum element length: | 500 mm (with measurement); 300 mm (without measurement) |

Maximum length of heating elements | See available versions |

Maximum length of terminal pin | 40 mm |

Number of programmable bends per cycle | n° 80 |

Bending speed | 360°/sec. |

Bending tool (pin/roll) diameter - heating elements 6,3 – 12,5 mm | 18-60 mm |

Bending tool (pin/roll) diameter - heating elements 12,5 – 16,0 mm | 33-60 mm |

Minimum length for the last straight section of heating element 6,3 – 12,5 mm | 45 mm |

Minimum length for the last straight section of heating element > 12,5 mm | 130 mm |

Power supply | V To be defined |

Pneumatic supply | 6 Atm |

Installed power | See available versions |

Discover the other products in our range