Rolling mill head overhaul: what it is and why it’s crucial

The rolling mill head overhaul service is an extremely important activity that guarantees and restores optimal operating conditions for the machinery and its functions. Unlike routine maintenance, rolling mill head overhauls are a more in-depth and complex intervention. However, they significantly extend the service life of the rolling mill and ensure product quality.

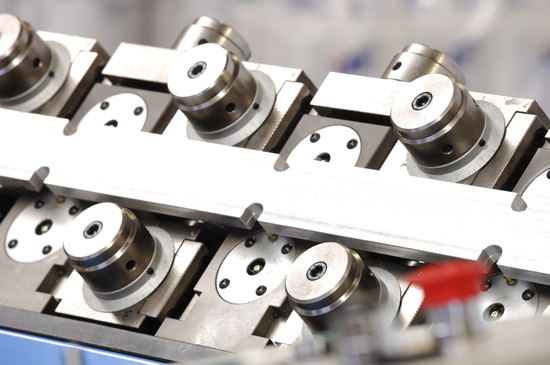

Periodic overhaul of rolling mill heads is a crucial operation to guarantee efficient production quality of heating elements. The heads are components subjected to extreme stress, and their correct functioning is directly linked to the precision of the rolling process.

The rolling mill heads contain the rolling dies, which are directly responsible for the shape and dimensions of the finished product. If the heads exhibit wear, misalignment, or damage, product quality is drastically affected. This leads to non-compliance with the straightness and dimensional tolerances of the electrical resistor, resulting in a non-uniform diameter.

Well-maintained rolling mill heads ensure a safer and smoother diameter reduction process. This translates into fewer machine downtimes, as unexpected blocks and interruptions are avoided, and a significant reduction in scrap material. This ultimately leads to considerable cost and time savings.

The heads and their internal components, such as rolls, bearings, shafts, bushings, and seals, undergo constant wear due to high forces, temperatures, and vibrations. Overhauling these elements is fundamental because it allows for the replacement of worn parts before a minor problem escalates into a serious and costly breakdown.

Why Entrust Your Rolling Mill Head Overhaul to CSM MACHINERY?

When it comes to overhauling rolling mill heads, choosing external professionals like CSM MACHINERY makes a substantial difference compared to a do-it-yourself approach.

CSM MACHINERY provides dedicated technicians who specialize exclusively in this type of operation. This means they possess deep, field-proven experience and expertise. Furthermore, they use precision tools that guarantee perfect alignment of the heads, a critical factor for the quality of the final product and the efficiency of the rolling process. Relying on CSM MACHINERY means choosing the guarantee of work performed to perfection, safeguarding the integrity and performance of your machinery over time.

Precision, efficiency, and reliability for production

The head overhaul service offered by CSM MACHINERY is designed to ensure maximum production efficiency through a meticulous and structured process. This process guarantees the complete restoration of the head and its readiness for immediate use. Each overhaul is performed in-house by specialized personnel and includes a series of cleaning, replacement, adjustment, and alignment interventions.

CSM MACHINERY‘s procedure follows these steps:

- Complete disassembly of the head and thorough cleaning of all components: turrets, nonios, and adjustment rings.

- Replacement of all wear parts: bearings, thrust bearings, oil seals, and sealing rings.

- Replacement of rollers, their shafts, and guide bushes.

- Restoration of alignment between the upper and lower rollers, achieved through micrometric measurements of distances between the roller shaft shoulder and the V-plate using high-precision instruments.

- Reworking of critical components in more delicate cases, performed with high-precision machine tools.

- Adjustment of turret rings to ensure symmetrical distance between the rollers, which is fundamental for the correct rolling process.

- Necessary adjustments to obtain the correct gap between the rollers and the alignment of the guide bushes for smooth and precise material passage.

Another added value of our service is the final adjustment performed with material supplied by the client. This guarantees the desired diameter reduction under real production conditions.

Once all operations are completed, the head is reassembled into the rolling mill, ready for reuse with maximum reliability. With a delivery time of approximately two weeks, CSM MACHINERY ensures a complete and highly professional head overhaul, guaranteeing optimal performance and long-term durability.

Want to dive deeper? Speak with our experts