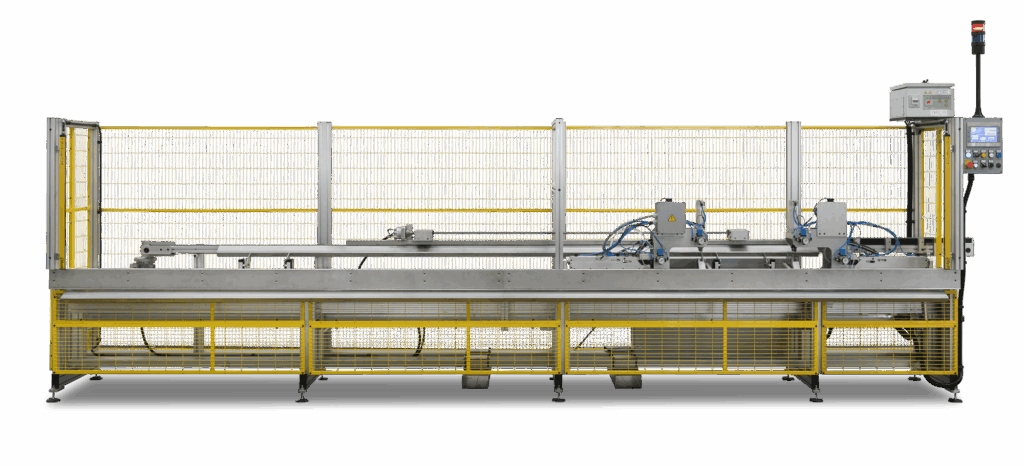

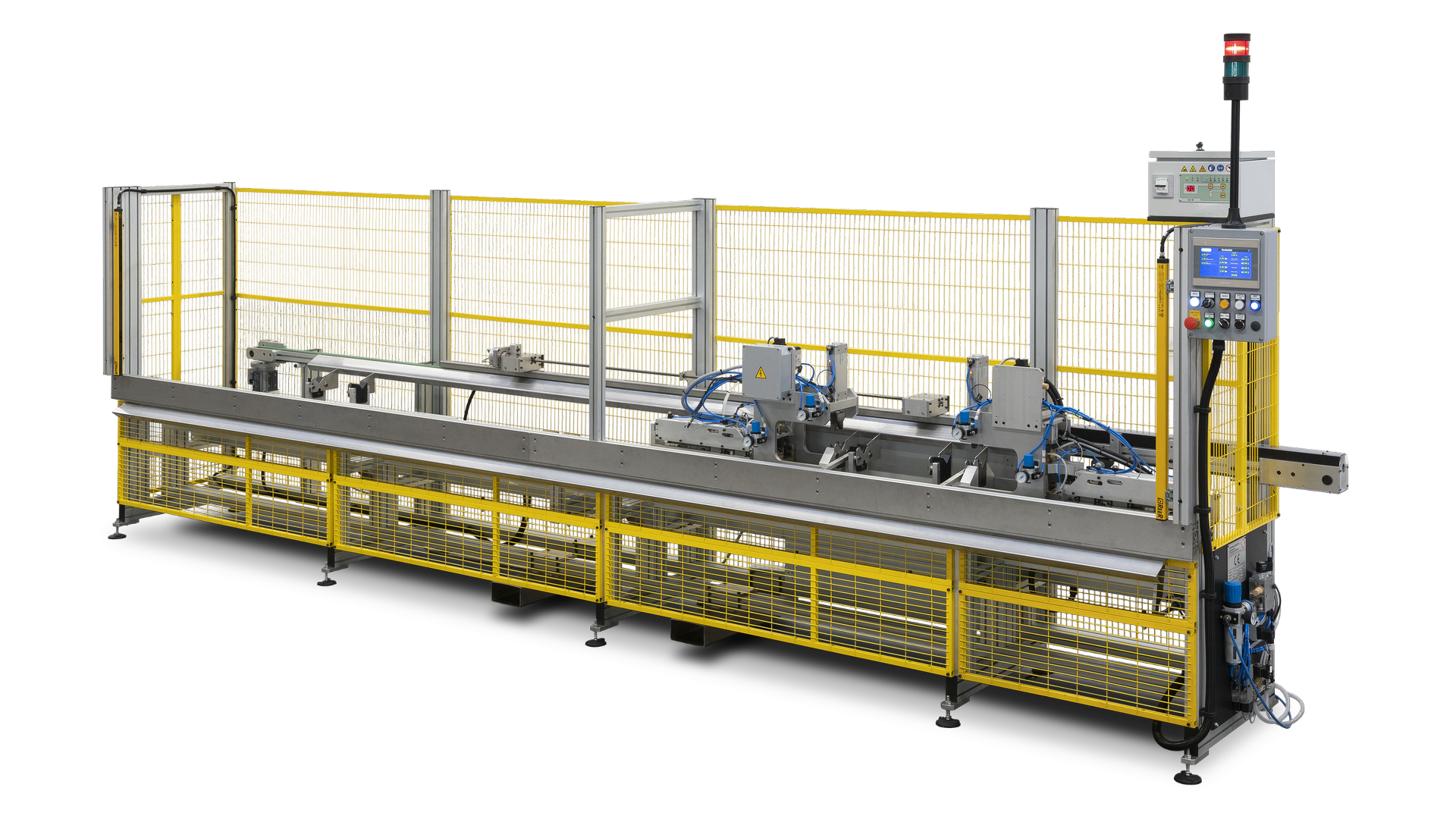

The CSM MACHINERY unloading device represents a state-of-the-art solution engineered to optimize the production of heating elements. Designed for seamless integration into existing production lines, this machine operates at high speeds immediately following the rolling mill, ensuring efficient collection and discharge of the heaters.

A key distinguishing feature of our solution is its fully automated plug removal function. The element exiting the rolling mill is directly fed into the removal plug station, where plug removal is achieved through precise pre-heating of the terminal area, followed by extraction using two pneumatic grippers. This automated process eliminates the need for operator intervention, making it ideal for managing medium-to-high production volumes.

The concrete advantages that make the difference

ideal for medium-to-high production volumes, eliminating the need for operator intervention.

and elimination of carbonaceous residues associated with potential stopper combustion.

with other machinery within the production process.

Discover all the machine details

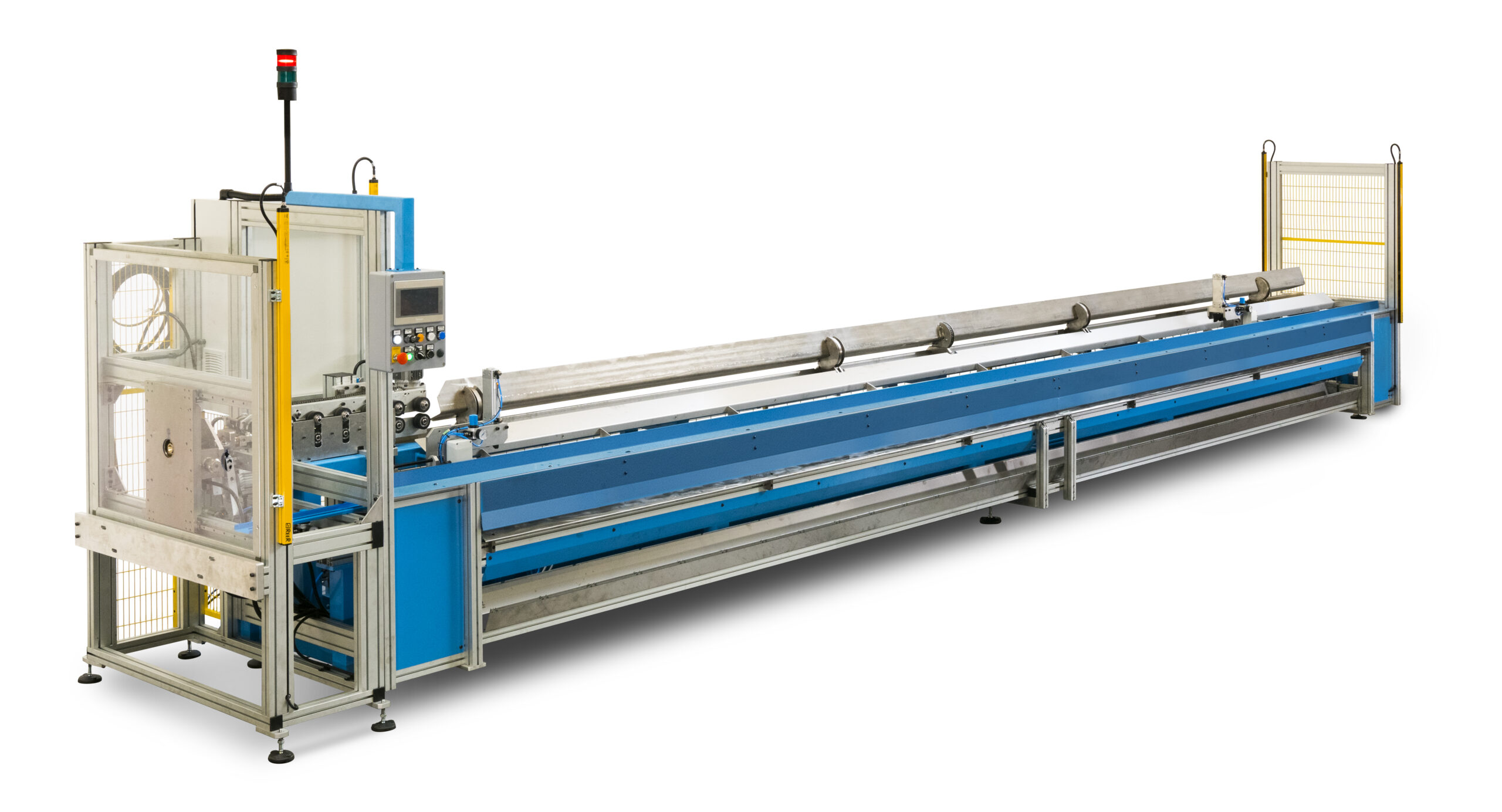

ELECTRONIC CONTROL OF THE HEATING UNIT

OPERATOR CONTROL PANEL

ROLLING MILL EXIT COLLECTION BELT

FIXED PLUG REMOVAL UNIT

MOBILE PLUG REMOVAL UNIT

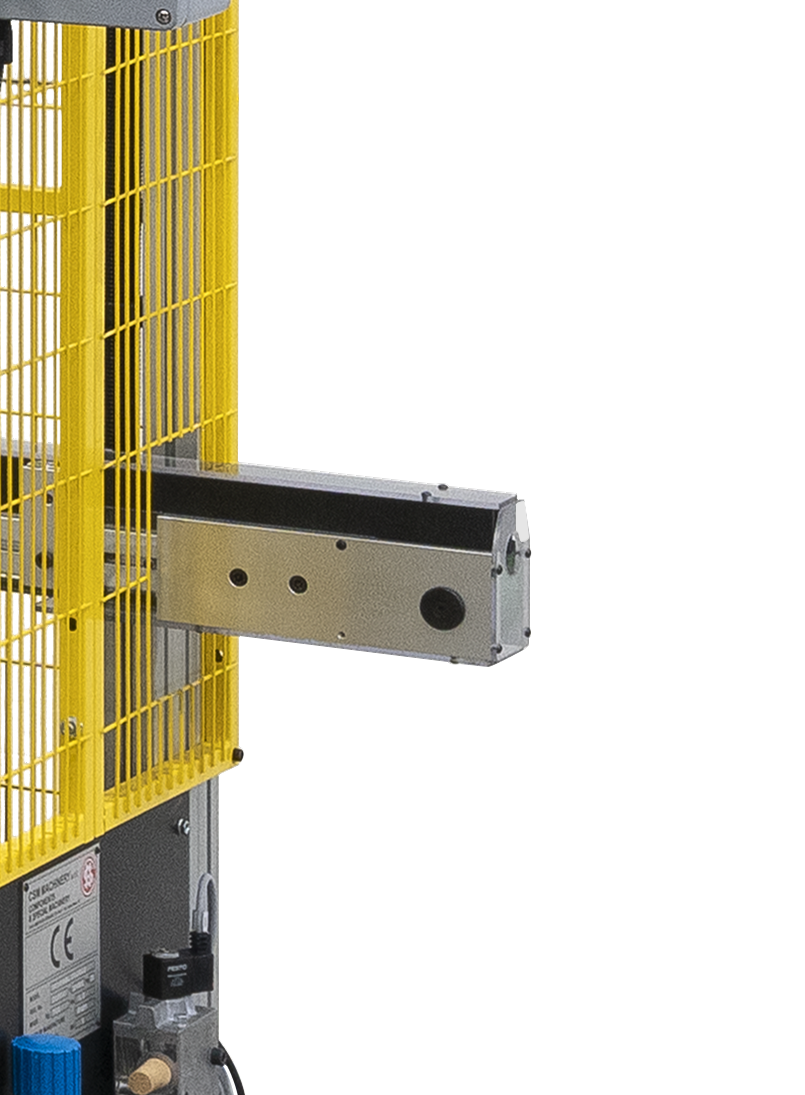

GRIPPING CLAMP

EXTRACTION CLAMP

ELECTRODES AND ELECTRODES HOLDER

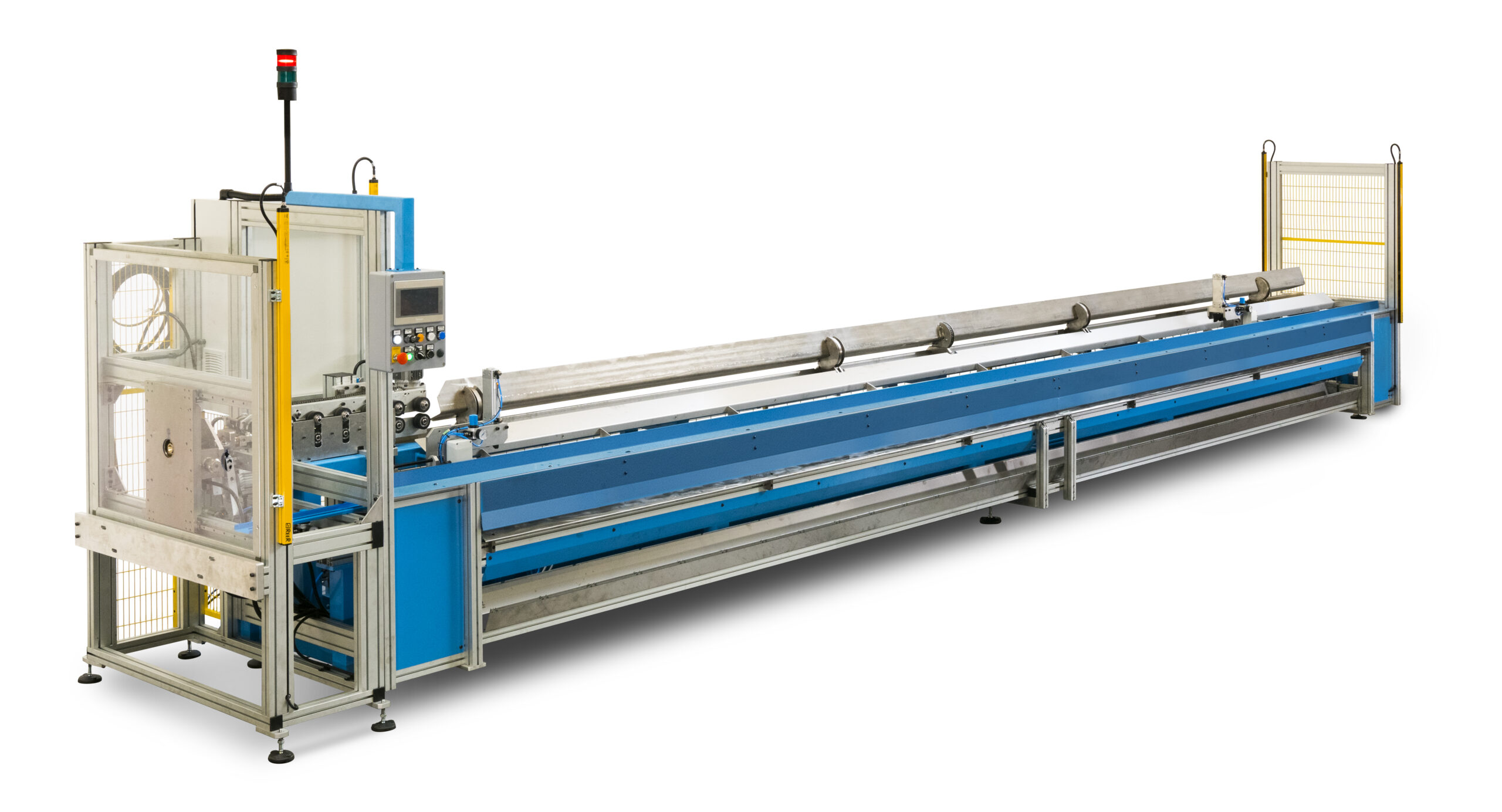

The device is designed to collect the heating elements which are exiting from the reduction rolling mill and convey them into a container, which is to be positioned at the machine’s base.

The device is designed to collect the heating elements which are exiting from the reduction rolling mill and convey them into a container, which is to be positioned at the machine’s base.

Discover the other products in our range