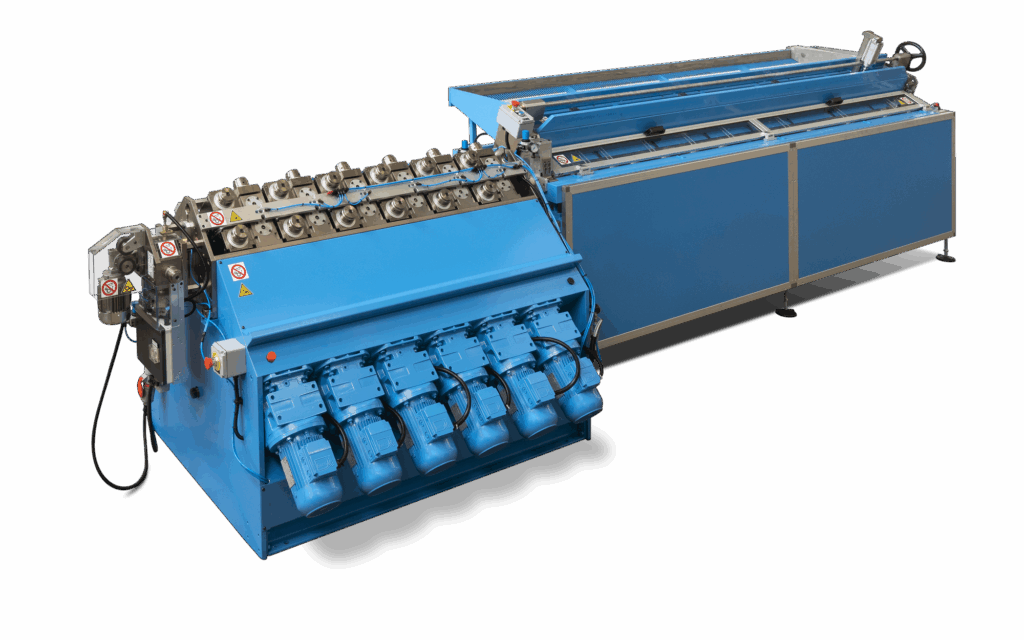

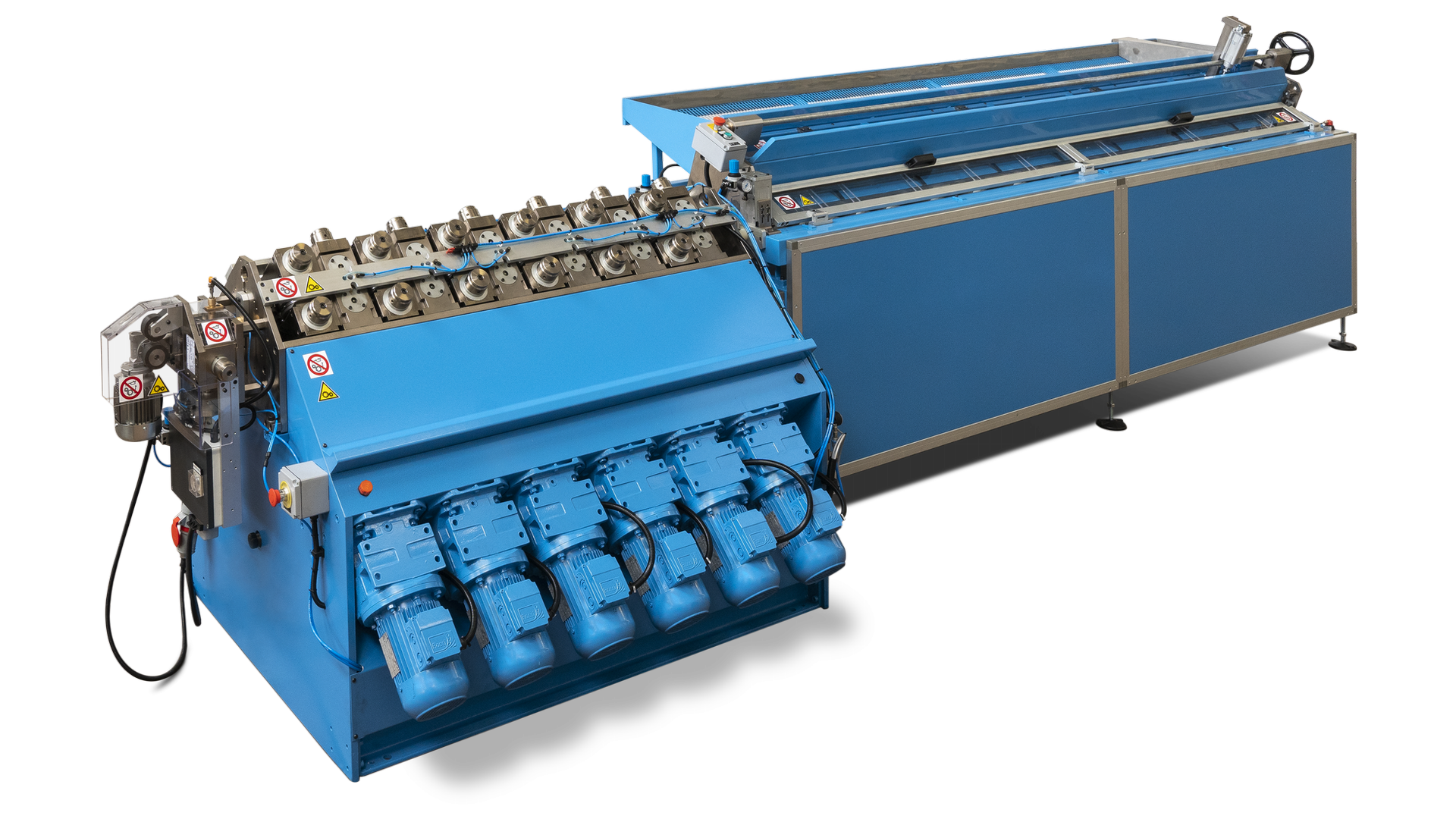

Designed by CSM MACHINERY, the automatic feeder for rolling mills ensures a continuous and precise flow of production. This solution significantly enhances the efficiency of diameter reduction processes by optimizing every operational phase.

The unit features a dedicated storage, an electropneumatic loading system for sequential feeding and motorized rollers that guarantee controlled and secure material introduction. Programmable synchronization capabilities allow for seamless integration into existing machine cycles.

Engineered to support advancements in production and to integrate with CSM MACHINERY automation solutions. This device reflects the company’s philosophy, which prioritizes productivity, efficient maintenance and advanced after-sales services.

The concrete advantages that make the difference

allows adaptation to various stainless steel tube diameters, optimizing every handling phase.

due to automatic management, aligned with CSM MACHINERY’s automation solutions.

maximize the output of subsequent processing stages.

Discover all the machine details

ELECTRO-PNEUMATIC DEVICE

for feeding one piece at a time.

HEATING ELEMENTS STORAGE

MOTORIZED ROLLERS FOR THE TRANSPORT

and introduction of the heating elements into the reduction mill, with the possibility of programming the feeding frequency.

POSSIBILITY OF ADJUSTING

the machine to different tubes diameters.

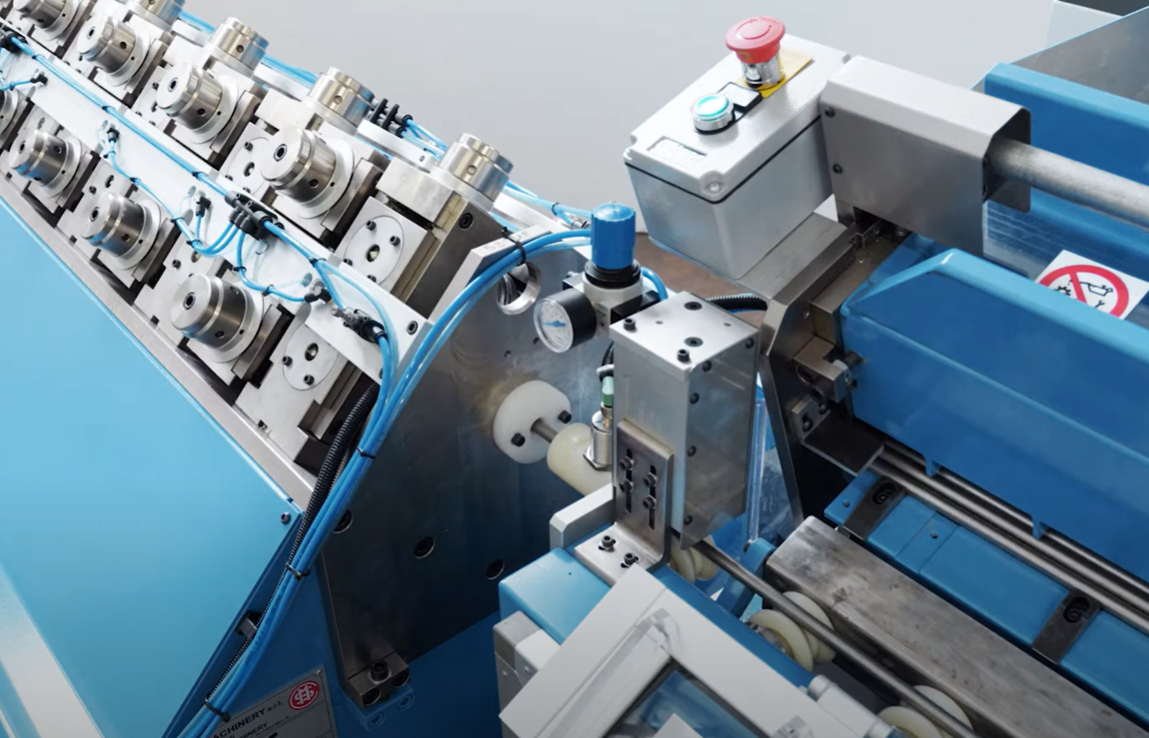

An appropriate instrument and its circuit ensure that the “Dielectric Strength” test is carried out on the heating elements before rolling, removing rejected pieces automatically.

A dielectric strength test before rolling has the following advantages:

The system is made up of:

An appropriate instrument and its circuit ensure that the “Dielectric Strength” test is carried out on the heating elements before rolling, removing rejected pieces automatically.

A dielectric strength test before rolling has the following advantages:

The system is made up of:

Storage capacity | pz. 100 (7,5) – 80(10) |

Length of heating element | mm to be specified |

Tube diameter | mm 7,5-14 |

Installed electrical power | Hp 0,30 |

Supply voltage | V to be defined |

Pneumatic power supply | Ate 6 |

Height of heating element axis from floor level | mm 850-950 |

Discover the other products in our range