In the production of heating elements, laminated elements can show length variations of up to 2%, which impacts the accurate distribution of dimensional tolerances. The CSM MACHINERY stretching machine is the ideal solution to compensate for these length differences, thereby optimizing the production process and ensuring maximum precision.

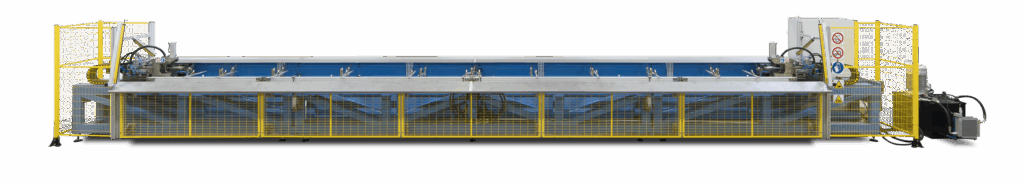

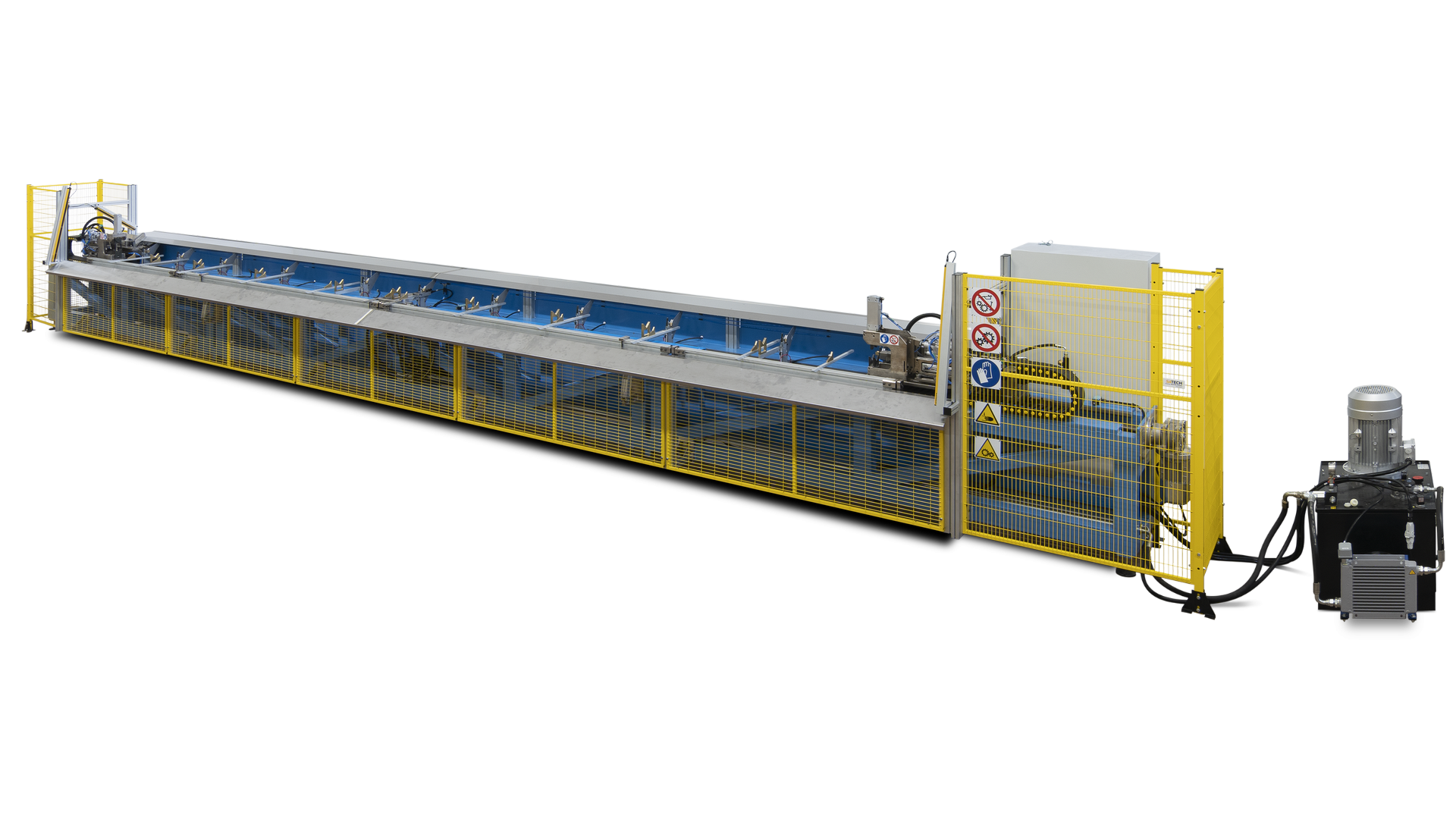

This machine, characterized by its simple yet robust construction, requires minimal maintenance. Its stretching action improves the linearity of the heating element, guaranteeing a superior final product quality. The CSM MACHINERY stretch-to-length machine is designed for use with heat-treated heating elements and is ideal for medium to large production batches.

The concrete advantages that make the difference

ideal for continuous production.

suitable for processing various tubular heating elements.

with direct benefits on the quality of the annealed tube.

Discover all the machine details

ELECTROPNEUMATIC DEVICE TO UNLOAD

the elements after the stretching cycle.

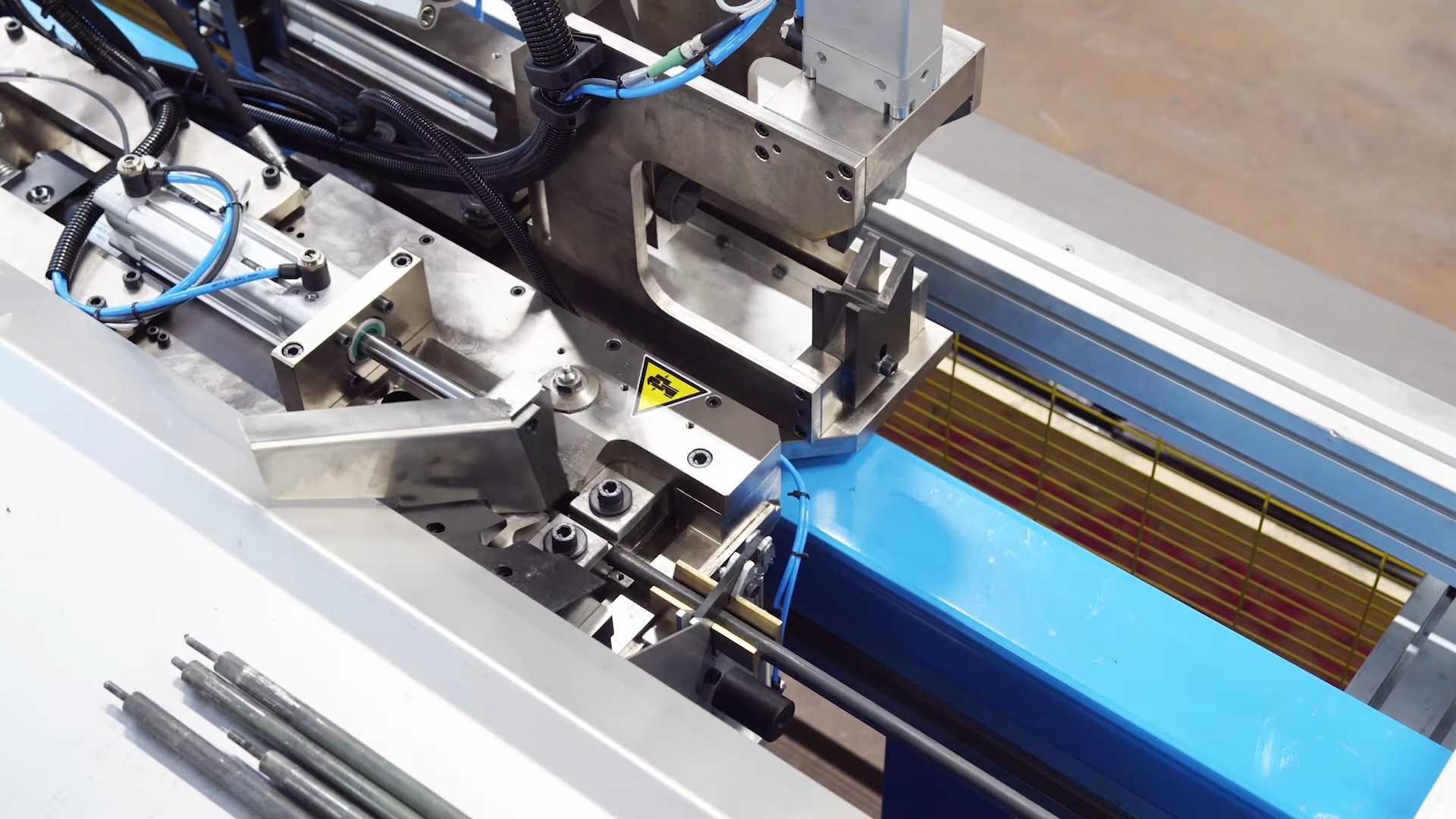

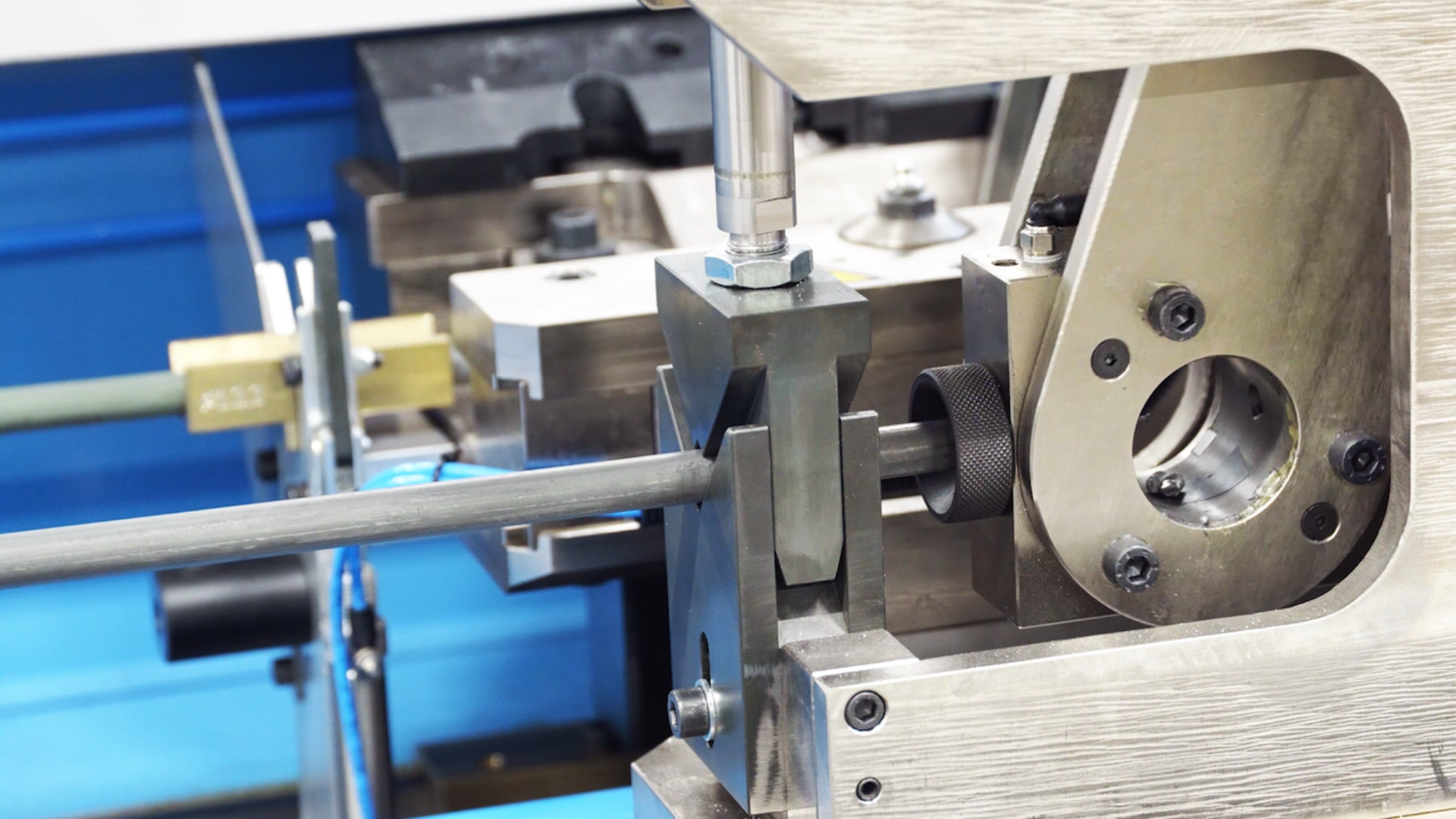

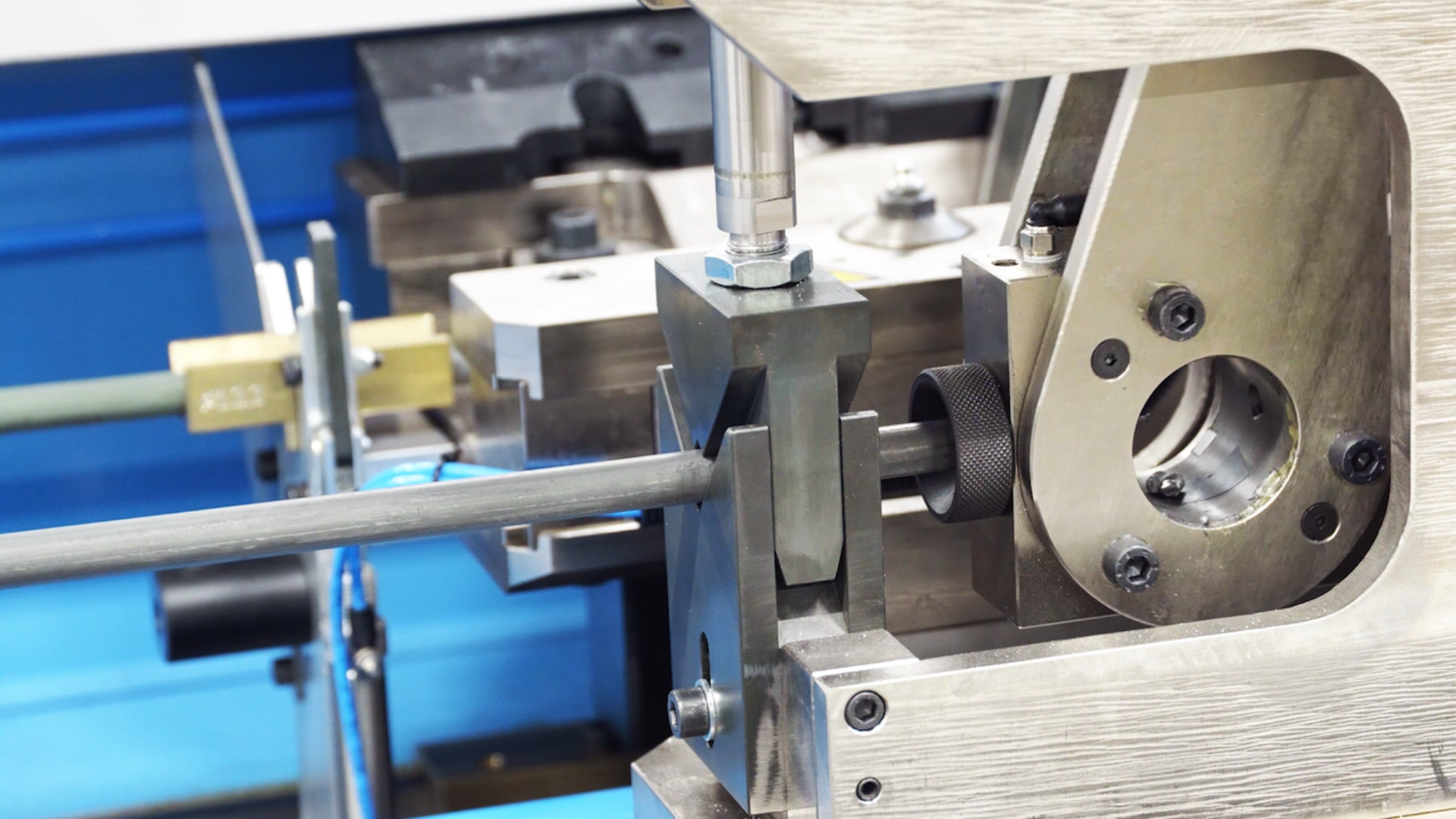

PNEUMATIC CLAMPS

to hold the elements to be stretched.

WELDED AND PAINTED STEEL FRAME

for the working units.

2 HYDRAULICALLYMOVED UNITS

to stretch the heating elements

ADDITIONAL STATIONS (NOT INCLUDED)

It is possible to add one only additional station to do in automatic an additional operation that can be added to the machine, such as: electrical tests, croppint to length of terminal pins, cleaning of terminal pins and electropneumatic devices to unload the element from the additional station.

It is possible to add a single additional station to the machine to perform an extra automated operation, such as terminal pin cropping. This is achieved using electropneumatic units with a rotating mandrel and the appropriate tooling.

It is possible to add a single additional station to the machine to perform an automated operation, such as electrical tests. This station can include an ohmic value measurement instrument (mod. 232/00), a dielectric strength tester (mod. 232/10), and a pair of pneumatically operated contacts.

It is possible to add a single additional station to the machine to perform an extra automated operation, such as terminal pin cropping. This is achieved using electropneumatic units with a rotating mandrel and the appropriate tooling.

It is possible to add a single additional station to the machine to perform an automated operation, such as electrical tests. This station can include an ohmic value measurement instrument (mod. 232/00), a dielectric strength tester (mod. 232/10), and a pair of pneumatically operated contacts.

Heating element length | 400-7000 mm |

Heating element diameter | 6,0-12,5 mm; 6,0-16 mm |

Initial length difference | % ±1,5 |

Length difference after stretching | ±1 mm |

Power supply | V da definire |

Pneumatic supply | 6 Bar |

Installed power of hydraulic unit | 7.5 KW |

Total installed power | 8.5 KW |

Setup time for length change | 2-3 min. |

Setup time for diameter change | 3-5 min. |

Terminal pin diameter | 2,5-3,5 mm |

Cutting length | 10-18 mm |

Ohmic range | 1.00-99.9 ohm |

Test accuracy | % ±1 |

Dielectric strength test voltage | 0-3000 V |

Dielectric strength test time | 1 sec. |

Maximum allowable current | 5 mA |

Discover the other products in our range