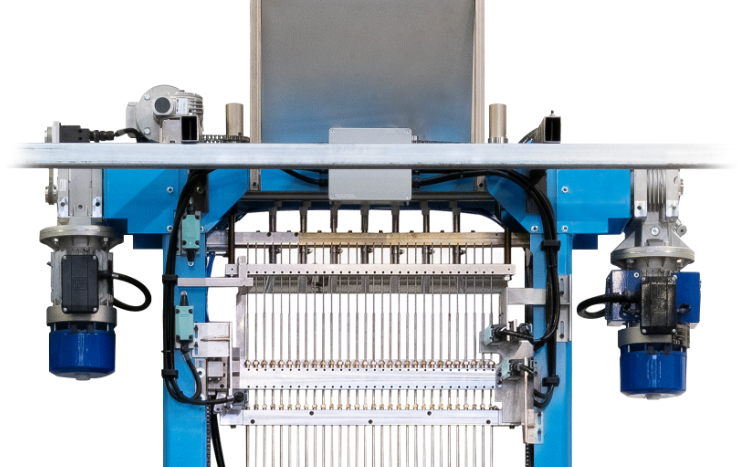

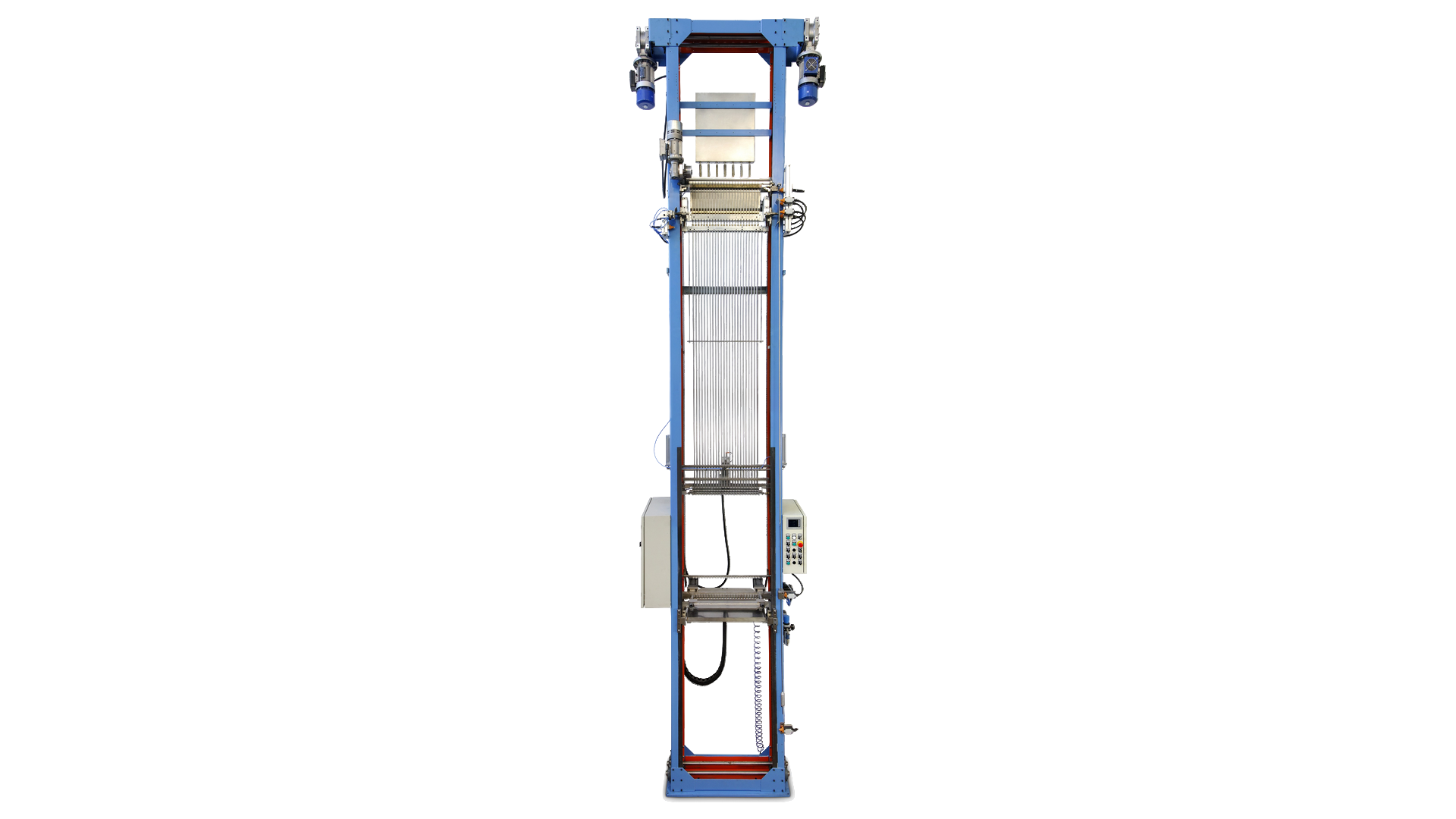

In addition to filling machines for double-sided tubular heating elements, CSM MACHINERY produces state-of-the-art machines for filling special heating elements, i.e. cartridge and monotube ones.

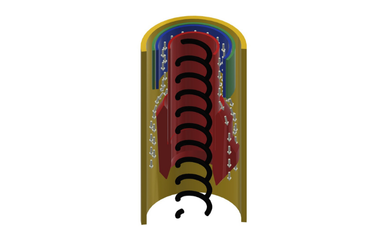

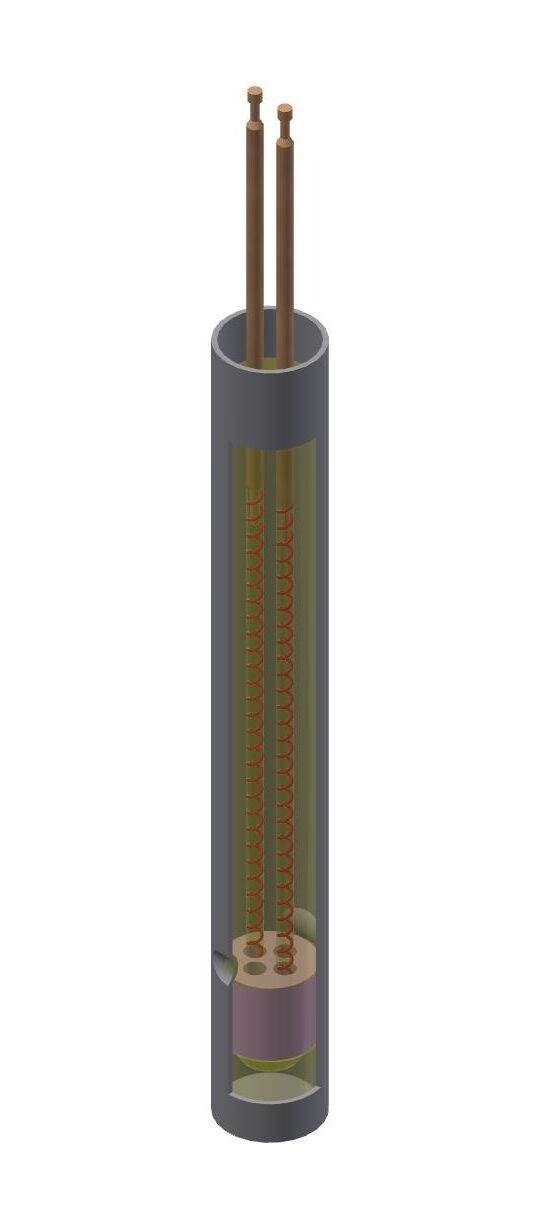

A monotube heating element is composed of two wound wires arranged side by side within a steel tube and isolated with magnesium oxide (MgO). The monotube filling machine is designed specifically for the filling of monotube heating elements that are characterized by a closed extremity and an open end in which two or more terminal pins are mounted.

The concrete advantages that make the difference

thanks to the new-patented 3-tube system for MgO flow control.

with electromechanical vibration system, driven by a d.c. motor and characterized by symmetrical oscillations.

when changing the length of the tubes to be filled and motorized adjustment of the top terminal pin protrusion from the tubes after being filled.

to facilitate fixing it in a vertical support position.

thanks to an intuitive operator interface designed for quick setup and control of the main functions of the machine.

through an encoder to determine the position of the vibrator group and avoid the collision of the pins with the lower bar.

Discover all the machine details

UPPER HOPPER

The hopper is designed to contain magnesium oxide (MgO), which will be inserted into the tubes.

TUBE CRIMPING GROUP

Hydraulic tube pressing unit to lock the inner coil in place. The hopper is designed to contain magnesium oxide (MgO) which will be inserted inside the tubes.

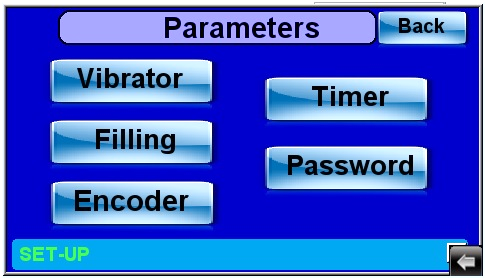

CONTROL PANEL

The operator interface is simple and intuitive and it facilitates more intuitive operation and allows for quick setting and control of the main machine functions.

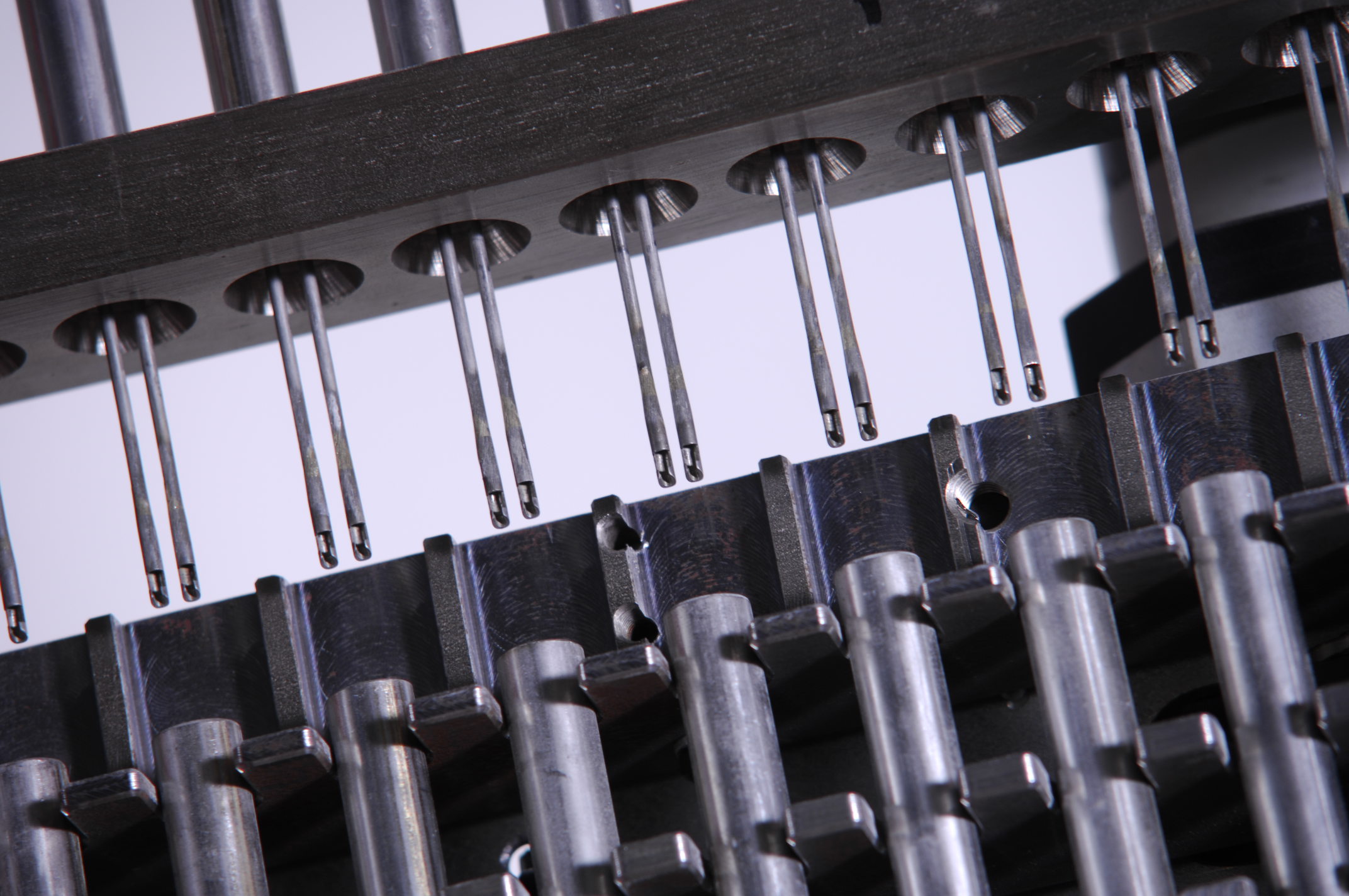

FILLING SET

New-patented 3-tube system for MgO flow control, which allows for greater filling speeds. The system is fitted with a mechanical closing/opening device that not only allows higher MgO flow rates, but keeps MgO from flowing once closed.

TANK MOTORIZATION

Motorised set up when changing the length of the tubes to be filled. Motorized adjustment of the top terminal pin protrusion from the tubes after being filled

MOVING HOPPER

Working hopper that moves together with the filling set.

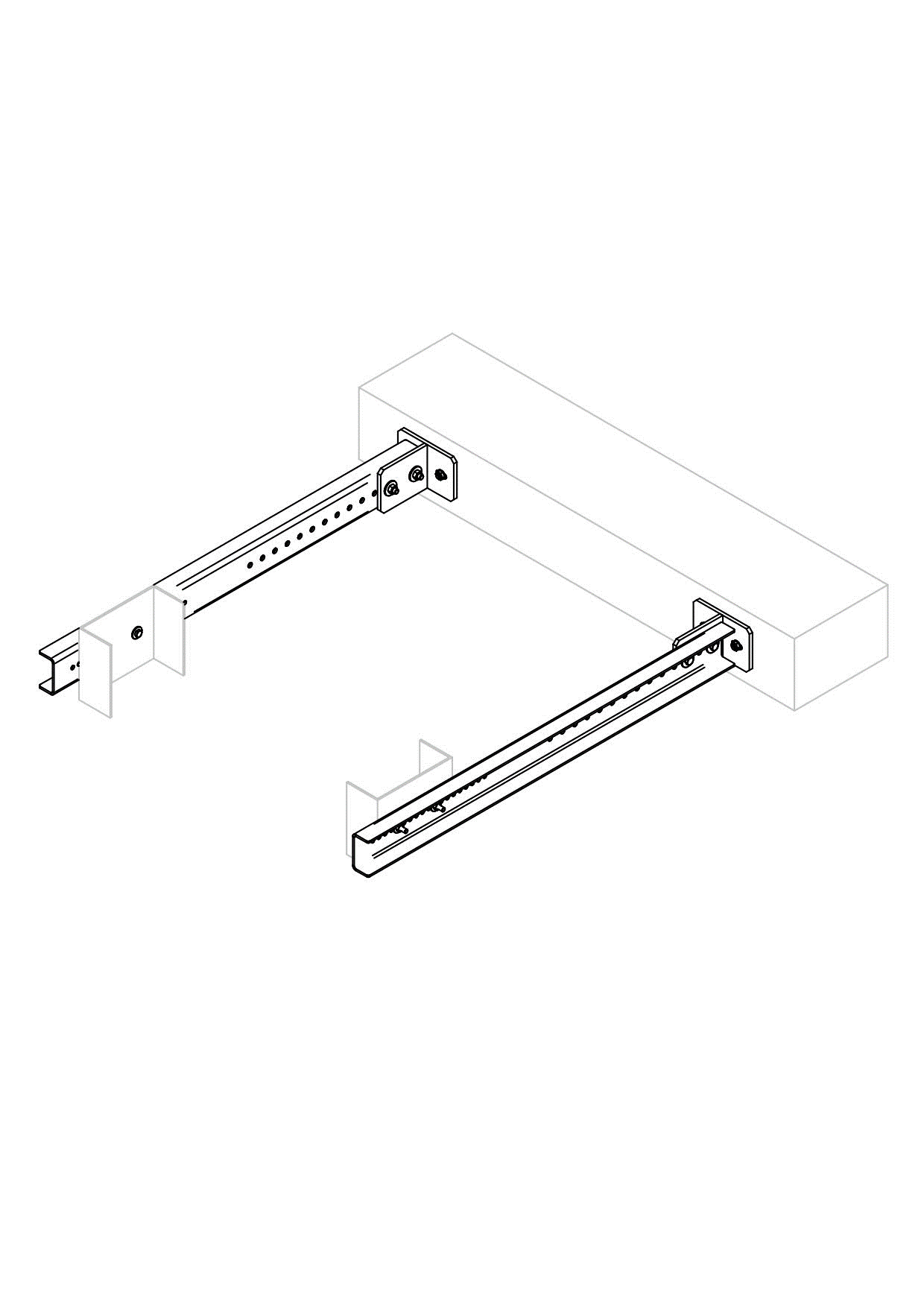

ADJUSTABLE BOTTOM BAR FOR TUBE SUPPORT

The position of the bottom bar is easily adjusted from the panel to accommodate different lengths of tubes to be filled.

VIBRATION GROUP

Electromechanical vibration system, driven by a d.c. motor. The system is stable and characterized by symmetrical oscillations even when varying the vibration frequency. By changing the rotational speed of the motor, it is possible to obtain different vibration frequencies. Travelling vibrator which moves from the bottom to the top of the tube during the filling process.

Manual adjustment of upper terminal pin extension | 25 mm |

Tube diameter to be filled | 10 - 22 mm |

Max. tube length to be filled | To be defined (mm) |

Min. tube length to be filled | 450 mm |

No. of tubes to be filled | To be defined |

Filling speed | 400 mm/min |

Vibration intensity (frequency) | Adjustable from 0 to 60 Hz |

Installed electric power | 3 Kw |

Power supply | To be defined (V) |

Pneumatic supply | 6 Ate |

Setup time for tube length change | 2 - 4 min. |

Setup time for terminal pin extension change | 5 - 7 min. |

Discover the other products in our range