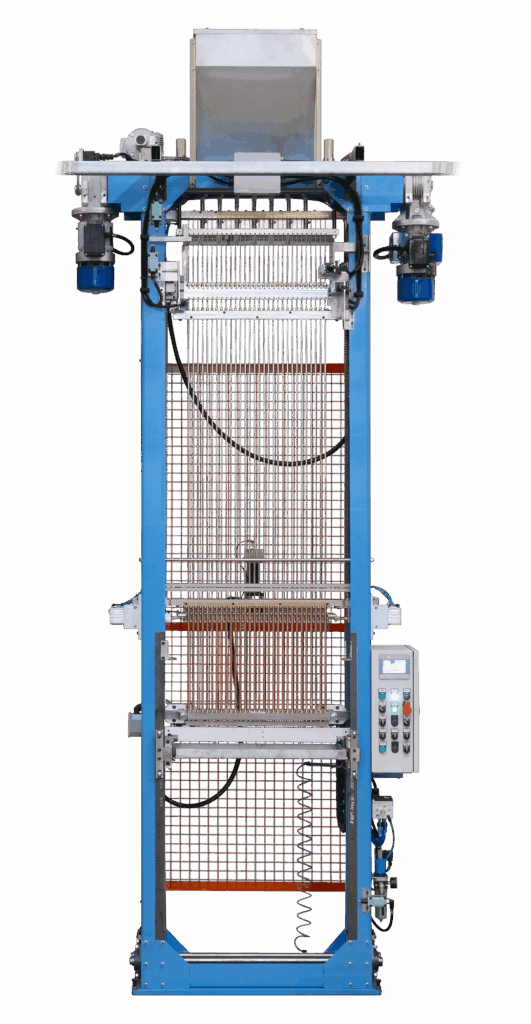

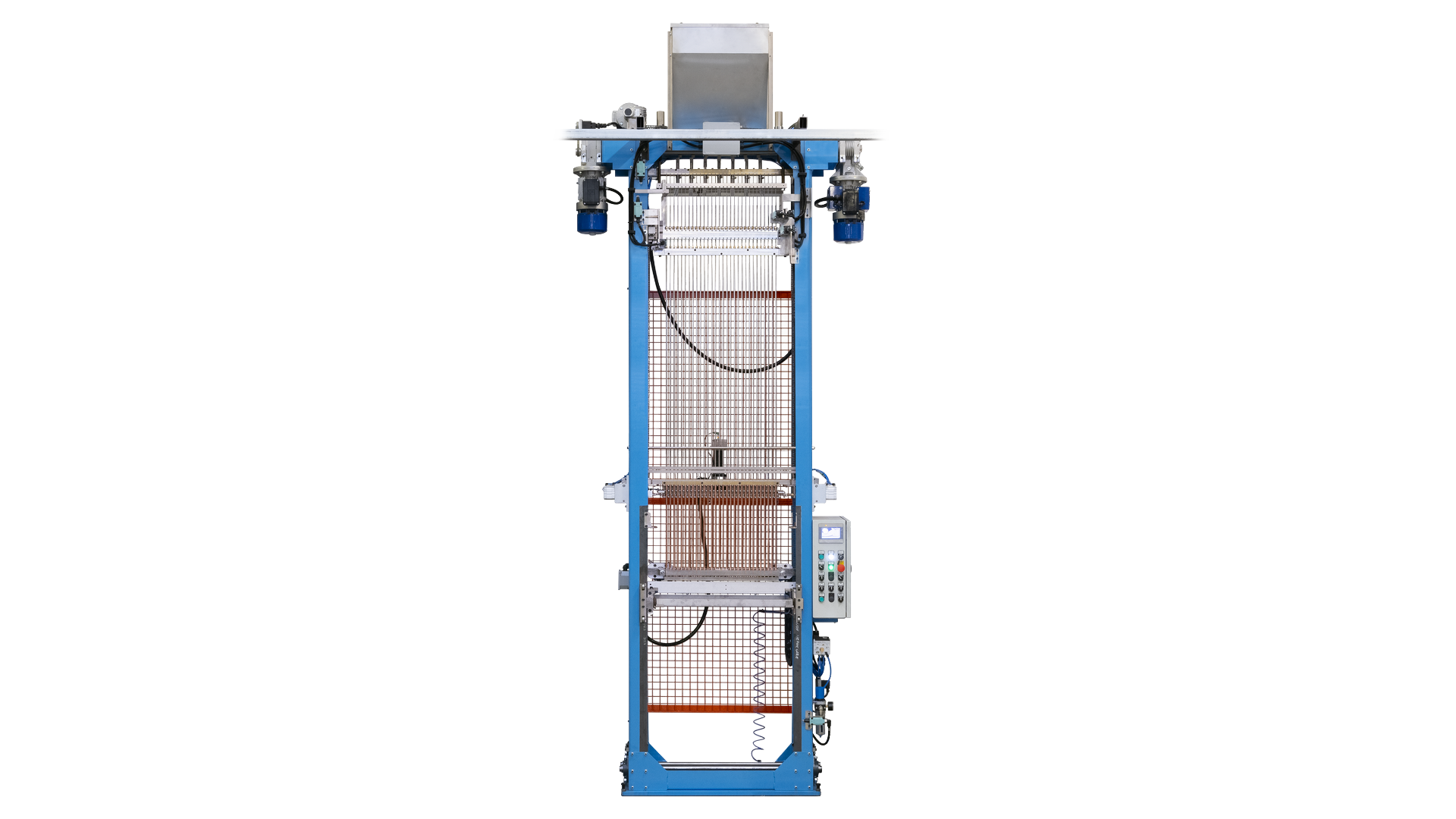

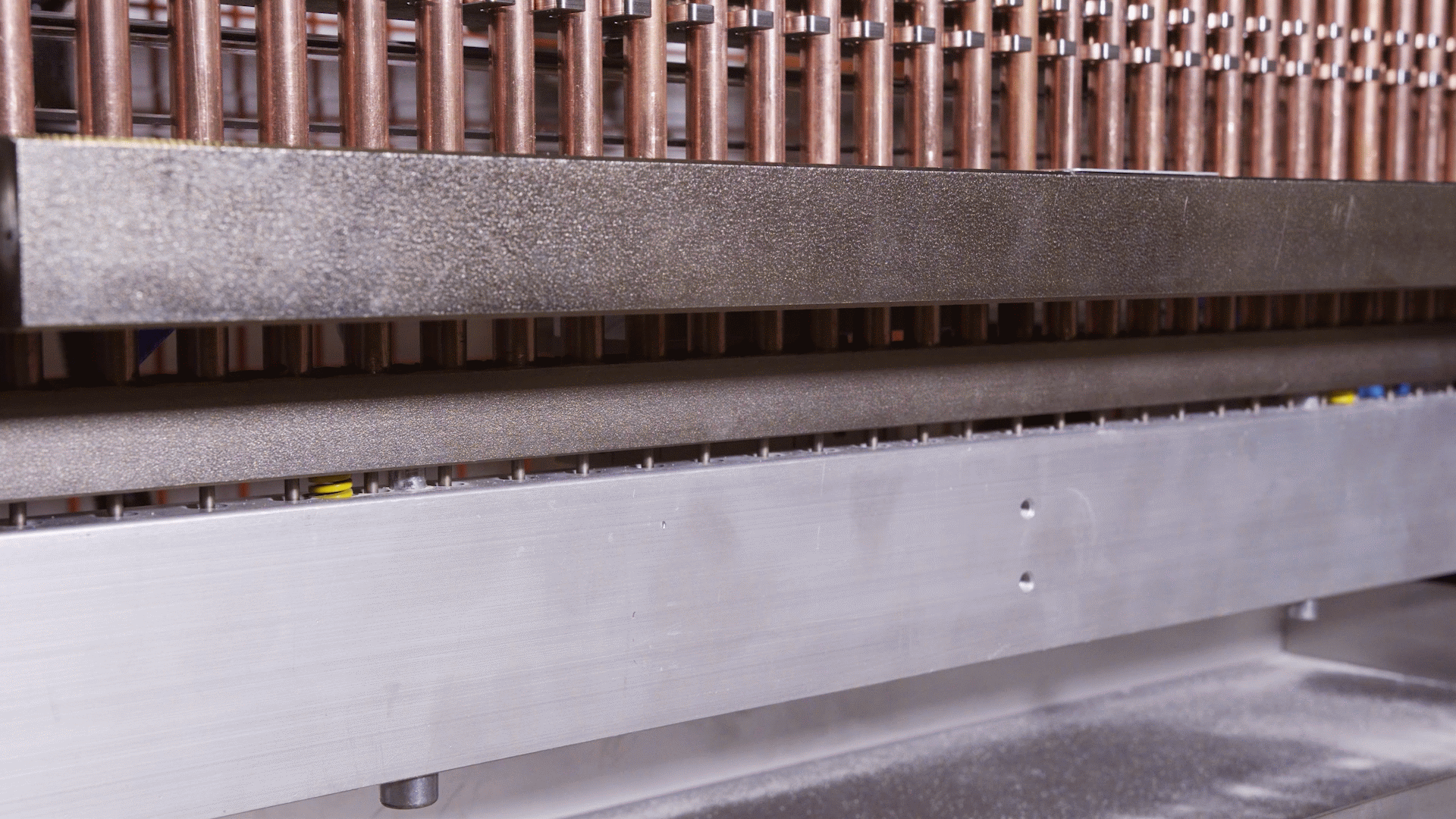

CSM MACHINERY filling machines ensure the accurate filling of heating elements with magnesium oxide (MgO). Thanks to a patented system for MgO flow control, the filling speed is increased and more effectively eliminates magnesium oxide leakage.

CSM filling machines operates using an electromechanical vibration system with precise amplitude and frequency settings that enhance the filling process. They are available in various configurations to meet each customer’s specific production needs.

The concrete advantages that make the difference

thanks to the new-patented 3-tube system for MgO flow control.

with electromechanical vibration system, driven by a d.c. motor and characterized by symmetrical oscillations.

when changing the length of the tubes to be filled and motorized adjustment of the top terminal pin protrusion from the tubes after being filled.

to facilitate fixing it in vertical support position.

thanks to an intuitive operator designed for quick setup and control of the main functions of the machine.

through an encoder to determine the position of the vibrator group and avoid the collision of the pins with the lower bar.

Discover all the machine details

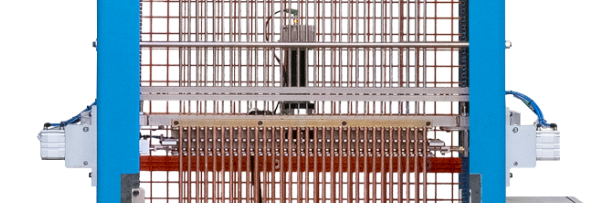

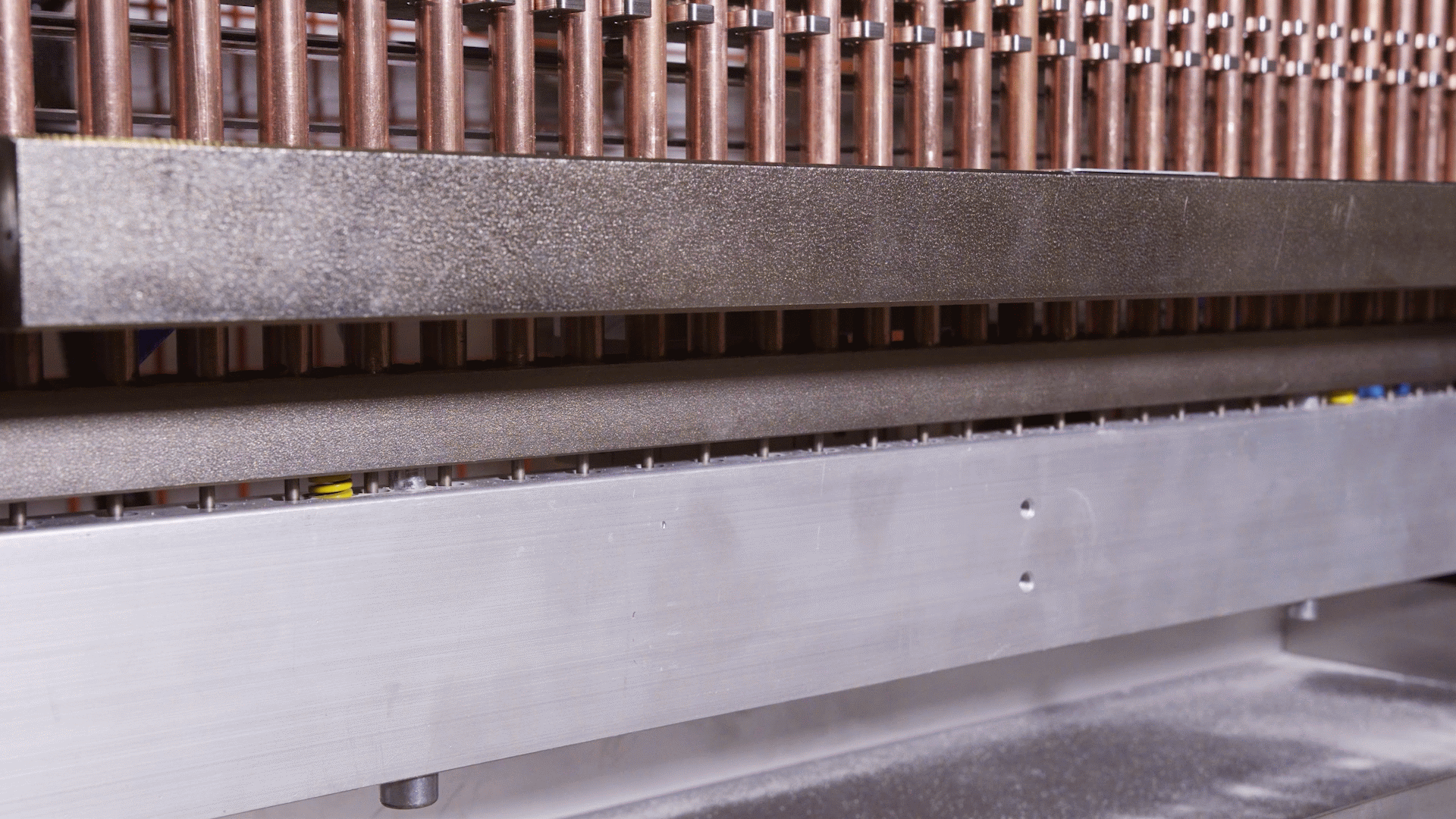

VIBRATION GROUP

Electromechanical vibration system, driven by a d.c. motor. The system is stable and characterized by symmetrical oscillations even when varying the vibration frequency. By changing the rotational speed of the motor, it is possible to obtain different vibration frequencies. Travelling vibrator which moves from the bottom to the top of the tube during the filling process.

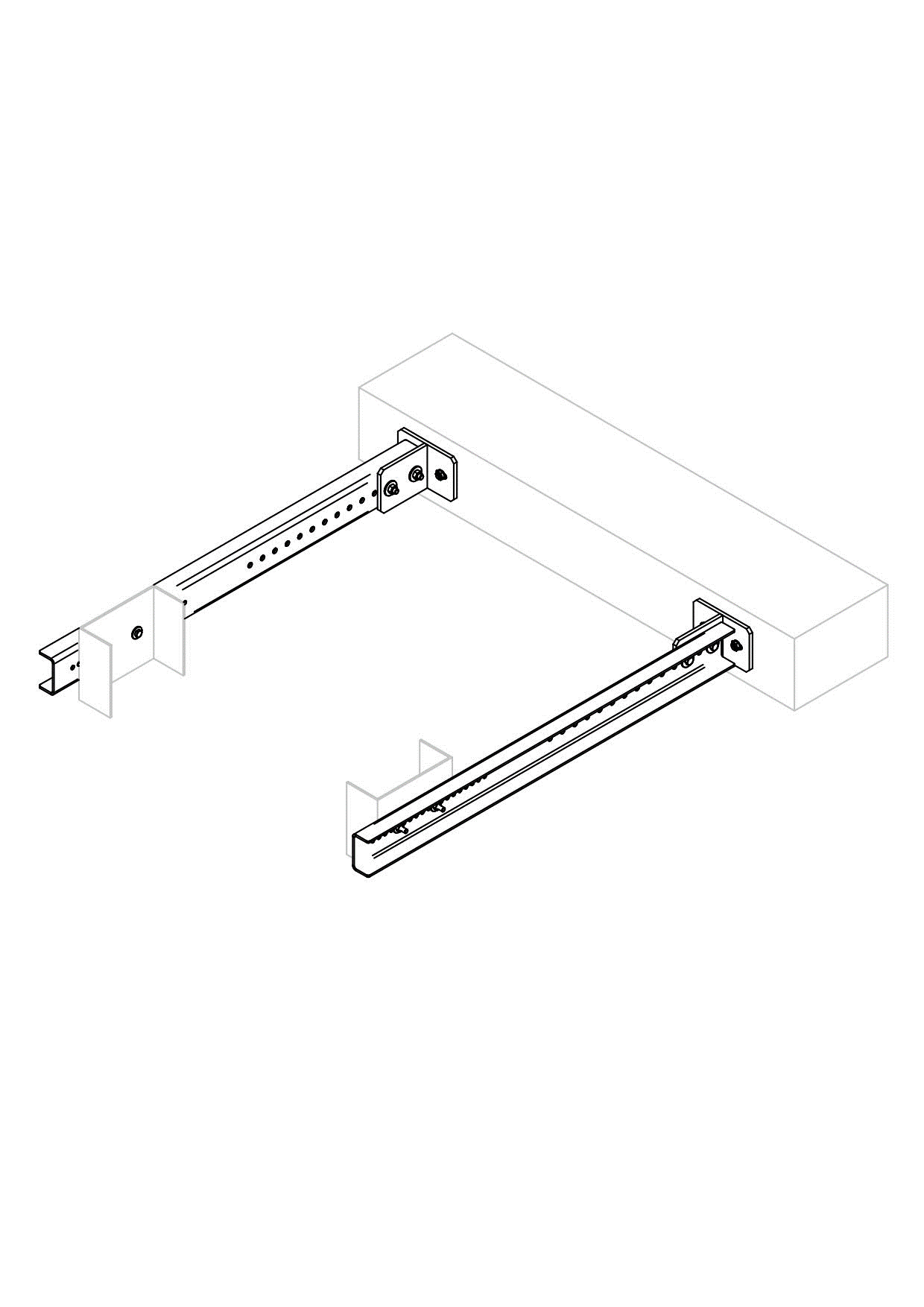

ADJUSTABLE BOTTOM BAR FOR TUBE SUPPORT

The position of the bottom bar is easily adjusted from the panel to accommodate different lengths of tubes to be filled.

UPPER HOPPER

The hopper is designed to contain magnesium oxide (MgO) which will be inserted into the tubes.

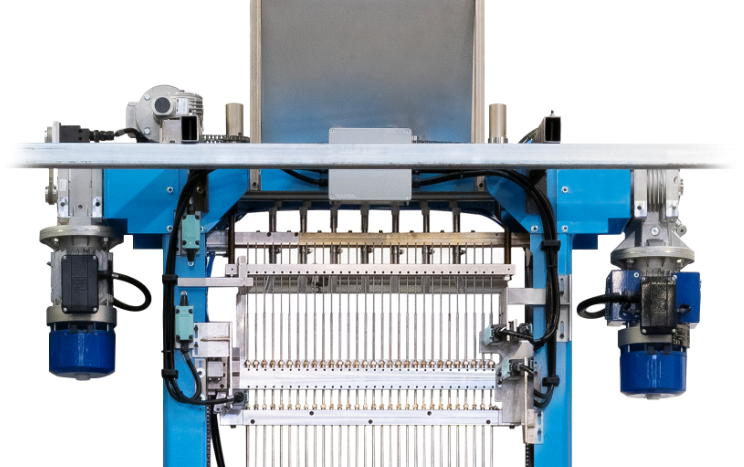

MOVING HOPPER

Working hopper that moves together with the filling set.

TANK MOTORIZATION

Motorised set up when changing the length of the tubes to be filled. Motorized adjustment of the top terminal pin protrusion from the tubes after being filled.

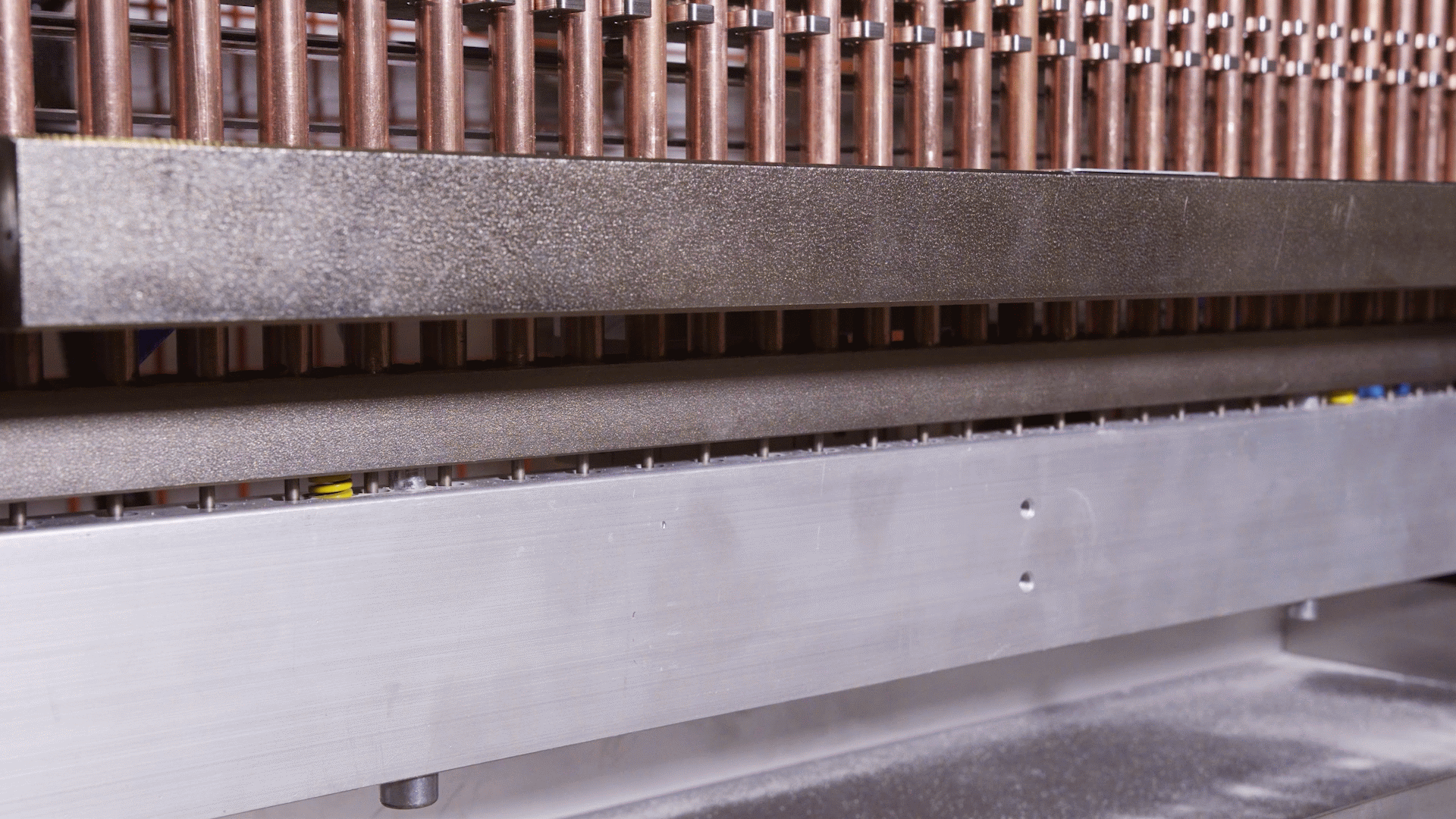

FILLING SET

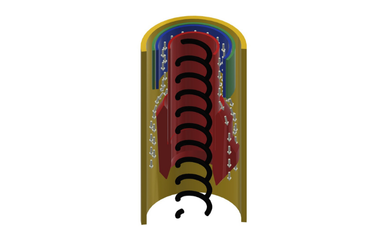

New-patented 3-tube system for MgO flow control, which allows for greater filling speeds. The system is fitted with a mechanical closing/opening device that not only allows higher MgO flow rates, but keeps MgO from flowing once closed.

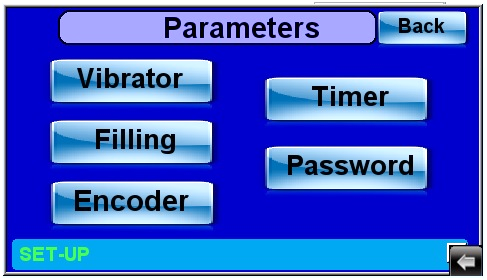

CONTROL PANEL

The operator interface is simple and intuitive and it facilitates more intuitive operation and allows for quick setting and control of the main machine functions.

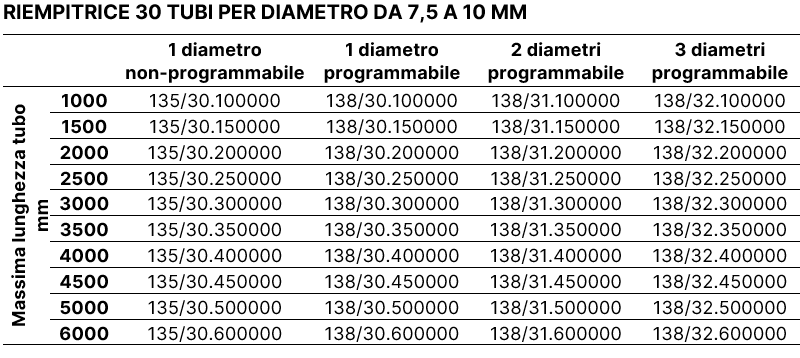

Machines can be designed to fill a single diameter or multiple diameters. Standard filling machines for tubular heaters are available in a non-programmable version, for simultaneous tube filling, and a programmable version, which allows you to set the number of tubes to be filled.

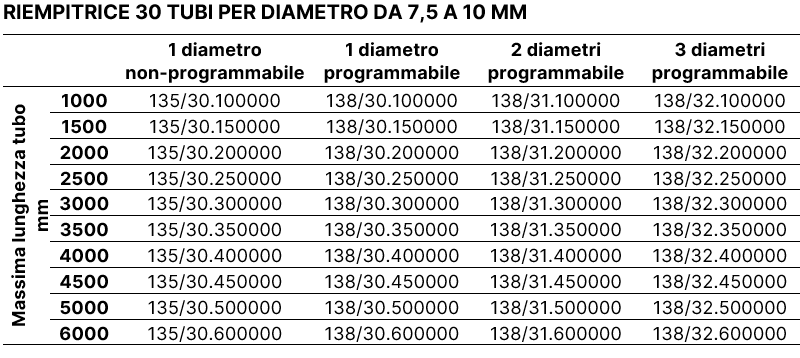

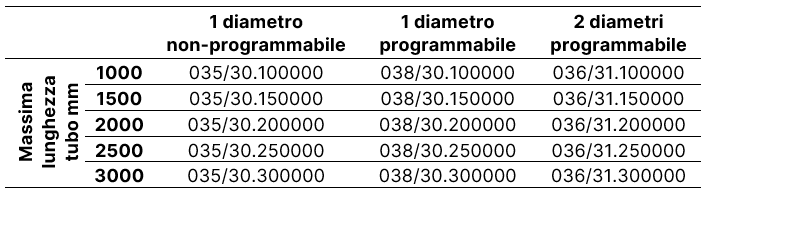

CSM’s 30-station filling machines can fill tubes with diameters ranging from 7,5 to 10 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

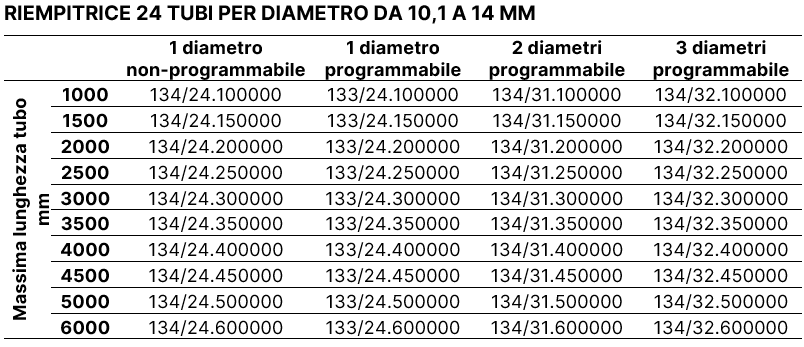

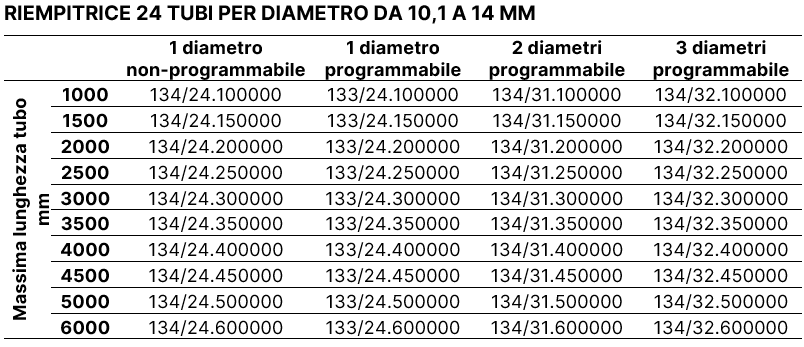

CSM’s 24-station filling machines can fill tubes with diameters ranging from 10,1 to 14 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

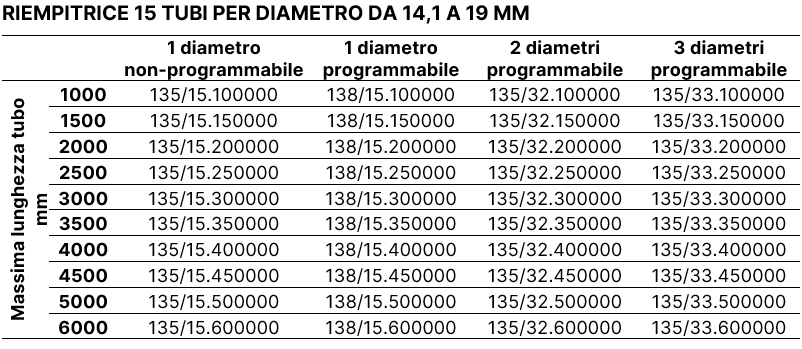

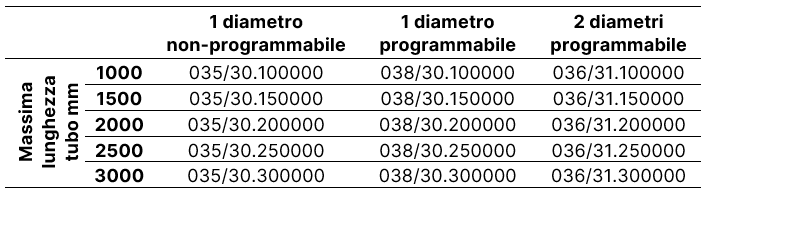

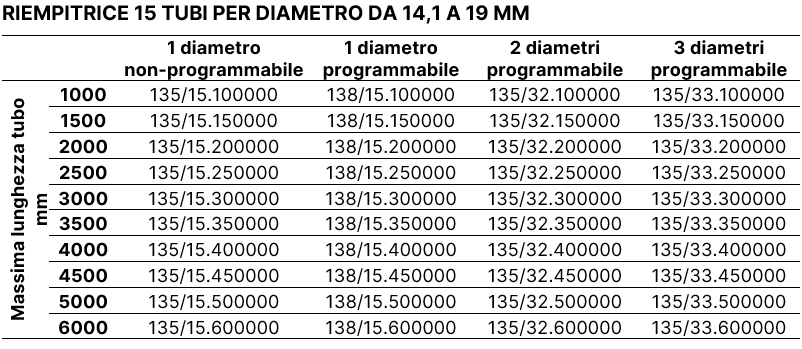

CSM’s 15-station filling machines can fill tubes with diameters ranging from 14,1 to 19 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

For diameters starting from 7,5 mm, the microtube filling machine system is fitted with a mechanical opening/closing device to open and then close the flow of MgO after a certain time from the start of fill. Because the size of the tube to be filled is too small to fit three filling tubes in it, it is necessary to use only two tubes with a device that closes the flow of MgO.

Machines can be designed to fill a single diameter or multiple diameters. Standard filling machines for tubular heaters are available in a non-programmable version, for simultaneous tube filling, and a programmable version, which allows you to set the number of tubes to be filled.

CSM’s 30-station filling machines can fill tubes with diameters ranging from 7,5 to 10 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

CSM’s 24-station filling machines can fill tubes with diameters ranging from 10,1 to 14 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

CSM’s 15-station filling machines can fill tubes with diameters ranging from 14,1 to 19 mm. They are available in both non-programmable and programmable versions, accommodating 1 to 3 diameters.

For diameters starting from 7,5 mm, the microtube filling machine system is fitted with a mechanical opening/closing device to open and then close the flow of MgO after a certain time from the start of fill. Because the size of the tube to be filled is too small to fit three filling tubes in it, it is necessary to use only two tubes with a device that closes the flow of MgO.

Unlock the mystery behind anomalous lengths!

Our verification test reveals the potential causes that compromise the filling quality of electrical heaters. Vibrating combs, filling sets, and uncontrolled settings can all impact the quality of your production. If you want to avoid costly maintenance issues, take a look at our guide!

Adjustment of upper terminal pin protrusion | 15 - 35 mm |

Tube diameters | see versions |

Max. tube length | see versions |

Min. tube length (filling machines up to 3000 mm) | 300 mm |

Min. tube length (filling machines >3500 mm) | 350 mm |

Number of tubes | 30 - 24 - 15 |

Max. filling speed | 600 mm/mi |

Vibration intensity (frequency) | da 0 a 60 Hz |

Installed electric power | 3 kW |

Power supply | to be defined (V) |

Pneumatic supply | 6 Ate |

Setup time for tube length change | 2 - 4 min |

Setup time for pin protrusion change | 1 - 2 min |

Discover the other products in our range