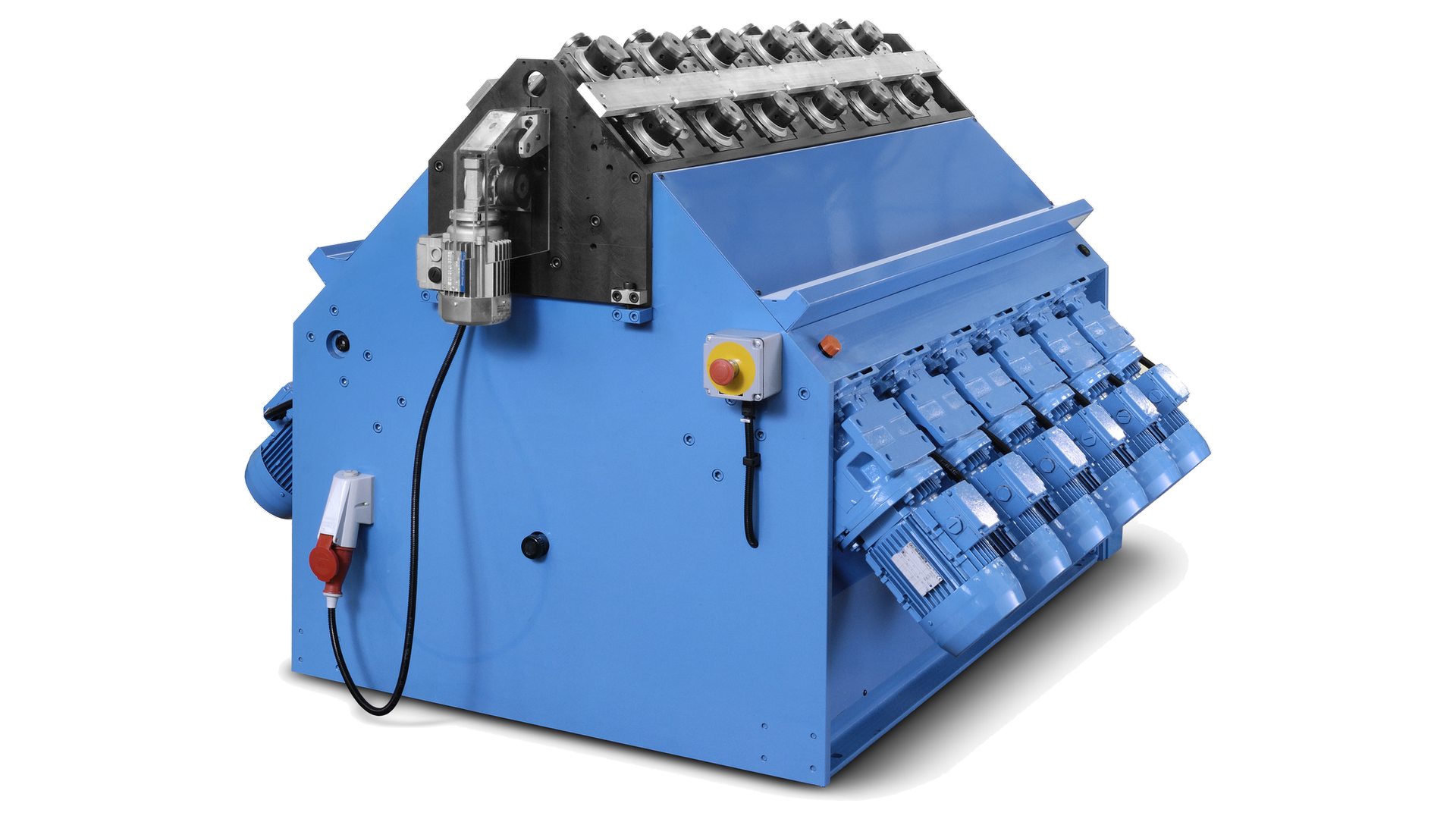

After filling, the elements are reduced to increase the density of the MgO. The roll reducer machine is designed to allow for tubular heating elements to be reduced in diameter, and for them to have a greater compression of the MgO and elongation. These machines feature interchangeable V-inserts that have the roll stands and rolls remounted and set for a particular reduction. This provides for very fast changeover times.

CSM MACHINERY’s reducing rolling mill can be equipped with automatic feeding equipment, a marking device and a lay-off table.

The concrete advantages that make the difference

The changeover time is approximately 30 minutes as opposed to six hours or more for changing a complete set of rolls.

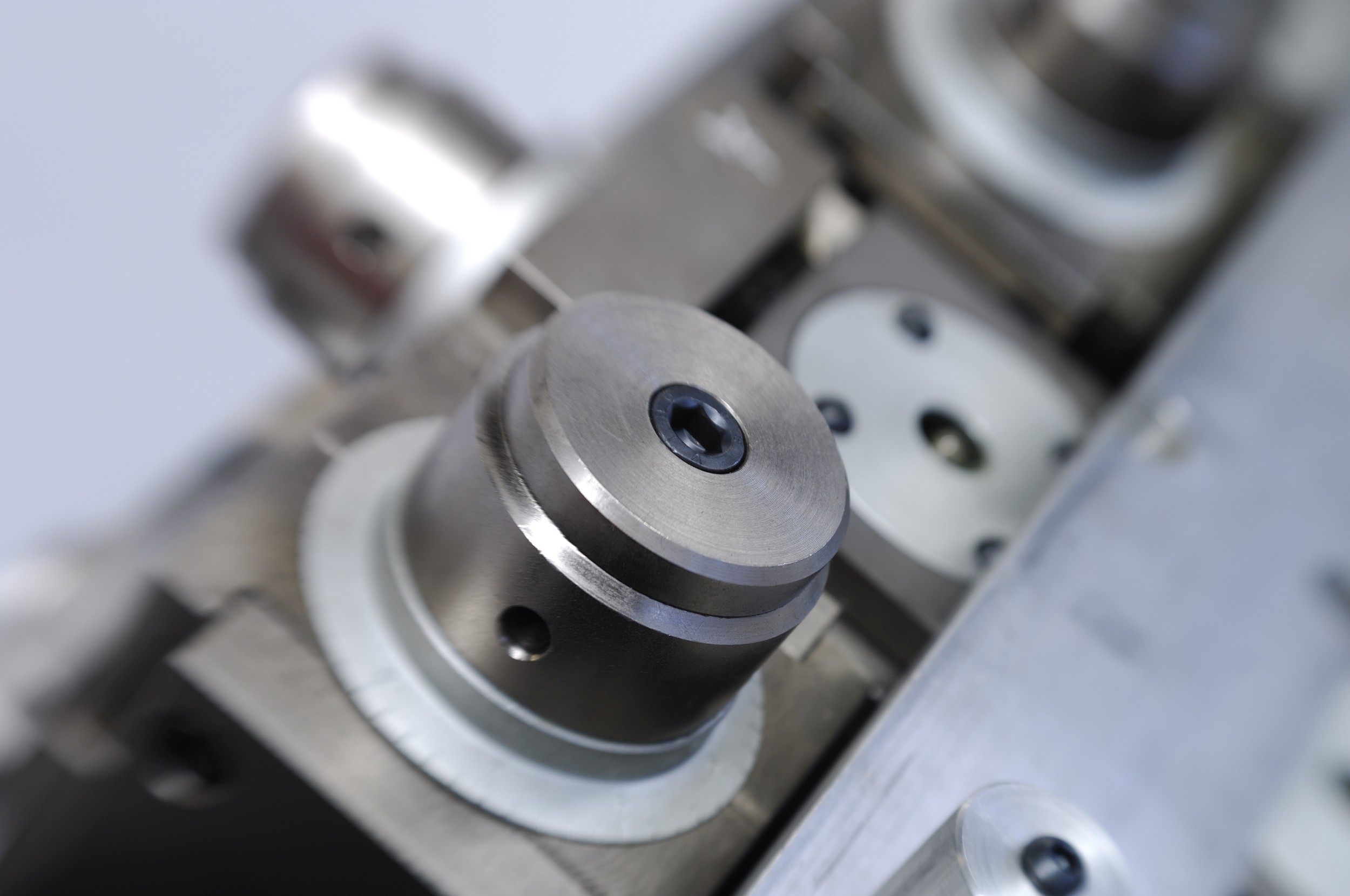

Rolls are manufactured of hardened alloyed steel or of steel with sintered carbide rings, which offer up to 4 times longer service than steel rolls.

that avoids any pounding nor vibration, and allows smooth, continuous, one-step reduction and roll locking system.

the machine is characterized by a low noise level.

.

thanks to straighter elements and accurate and consistent diameters.

to integrate automation solutions, automatic loading/unloading systems, and other machinery for stainless steel tube processing.

Discover all the machine details

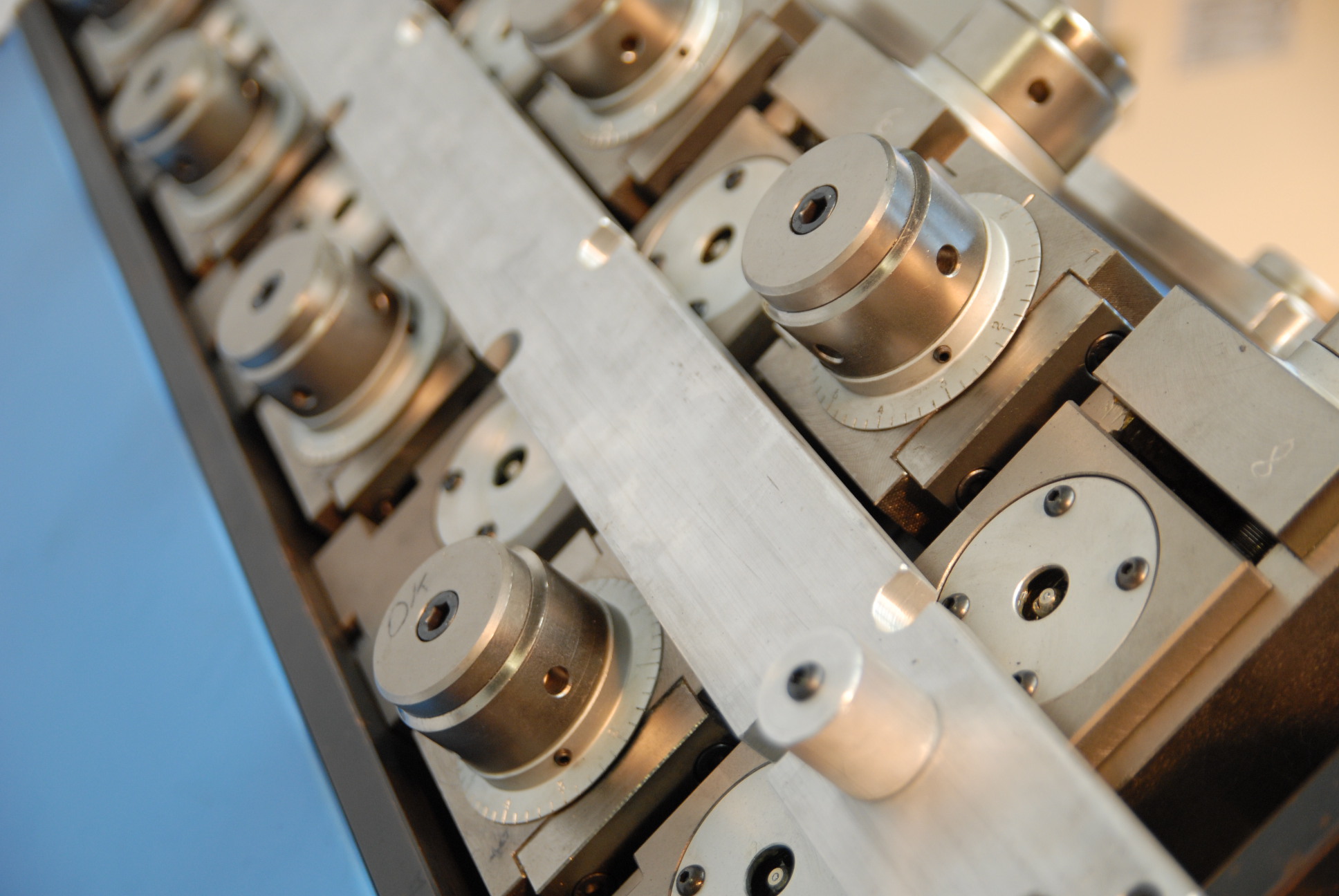

TRANSMISSION SHAFTS

which connect rolling mill head and its stand.

MACHINE STAND

with motors, gearboxes and electrical system with 8 or 12 stations.

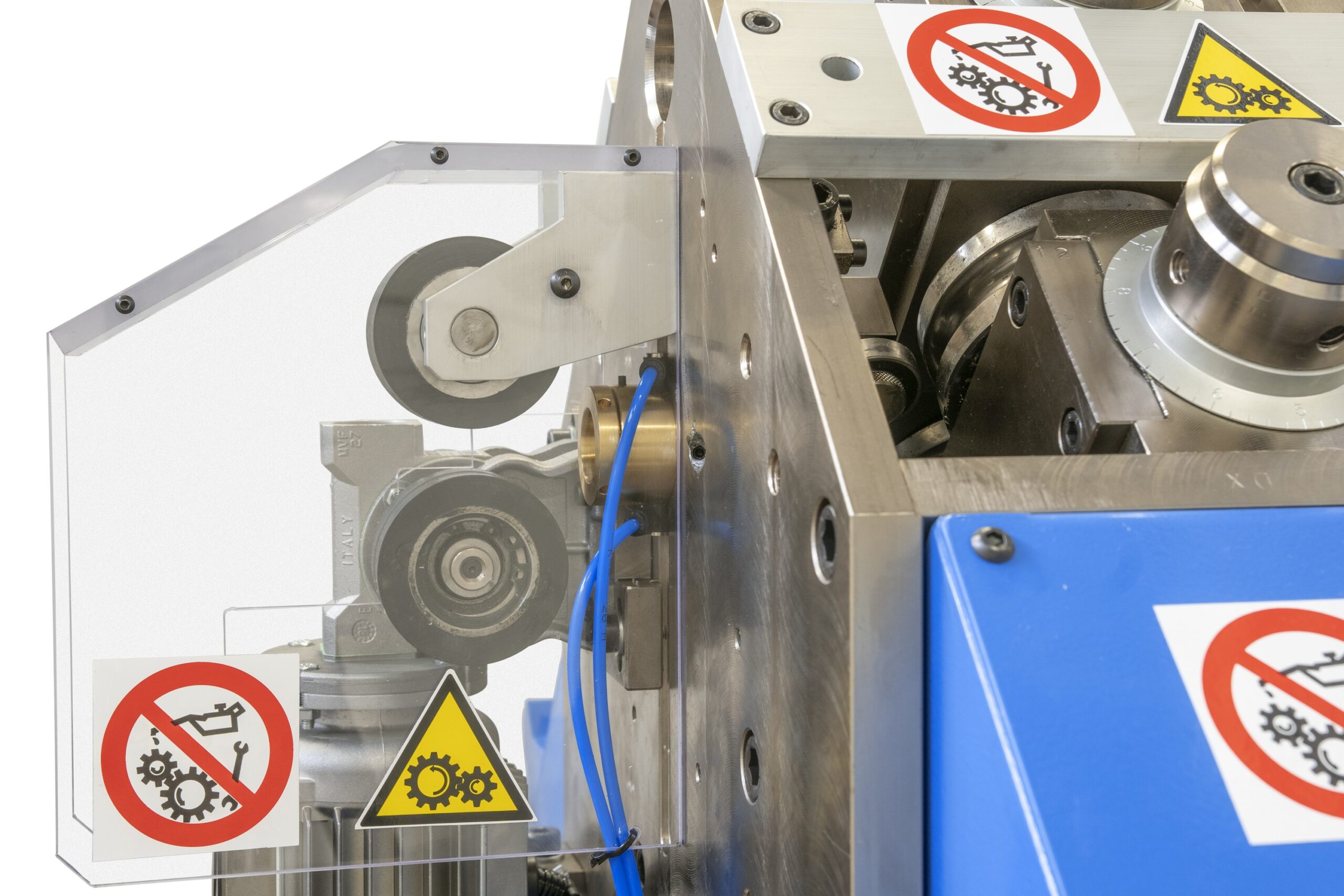

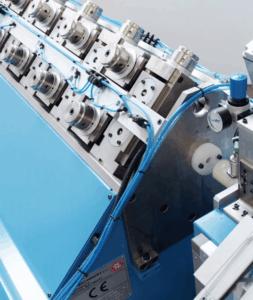

HEAD COMPLETE WITH EXTRACTION UNIT

with steel or tungsten carbide rollers. The head can be changed in approximately 30 minutes.

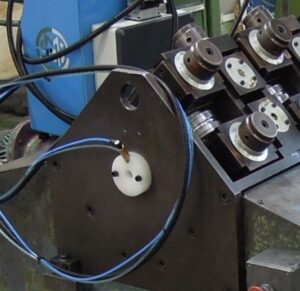

GUIDE BUSHINGS

interposed between each pair of rollers, ensuring the passage of the heating elements during the rolling process from one roller to the next.

MOTORIZED RUBBER ROLLER SYSTEM

which are positioned outside the rolling mill to extract the tubes.

ROLL-STRAIGHTENER (TURK’S HEAD)

(other straightening machines available upon request).

A set of tear and wear parts, made of a set of guide bushings and two rubber rolls (to draw the tubes out of the mill). Some lubricants can be used to increase the straightness of the element.

Roll lubrication system for rolling mill complete with spray nozzle located in the entry bushing.

Roll lubrication system for an 8 or 12 station rolling mill for single head complete with spray nozzles and outbound blow-drying.

A set of tear and wear parts, made of a set of guide bushings and two rubber rolls (to draw the tubes out of the mill). Some lubricants can be used to increase the straightness of the element.

Roll lubrication system for rolling mill complete with spray nozzle located in the entry bushing.

Roll lubrication system for an 8 or 12 station rolling mill for single head complete with spray nozzles and outbound blow-drying.

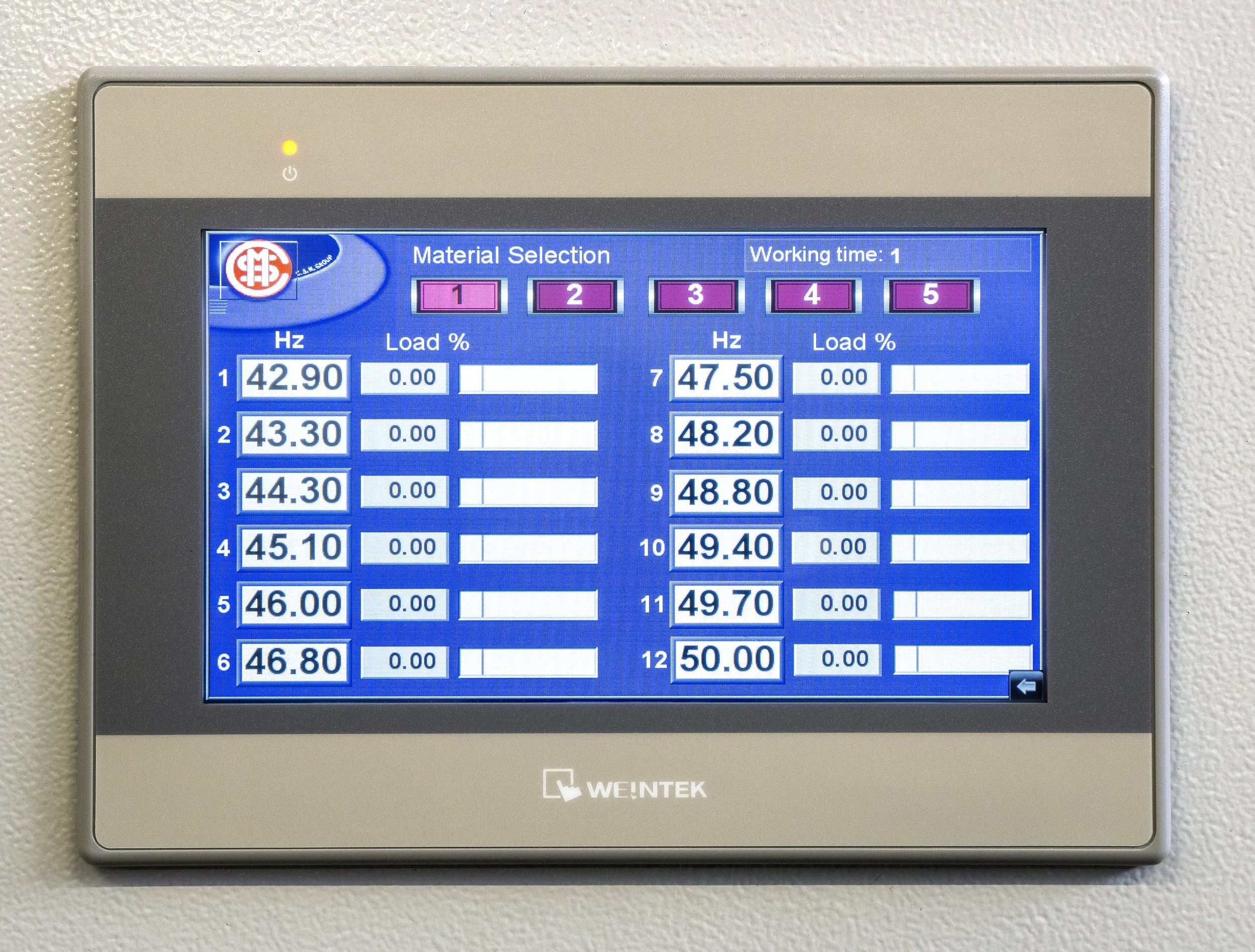

In the rolling mill with a fixed roll rotational speed, each pair of rolls is motorized via a fixed-speed geared motor.

In the rolling mill with a variable roll rotational speed, there is the possibility to program the rotation speed for each pair of rolls through frequency inverters, depending on the elongation of the elements. This solution allows to set the machine for different tube materials. Five sets of program scales of roll speed are available. Each pair of rolls will have a speed corresponding to the elongation of the tube, depending on the tube material. Having control of the speed of each roll station, it is possible to match as closely as possible the elongation occurring. This means that there is less friction between the rolls and tube, and therefore less heat generated by friction. As a result, the rolls last longer and the elements exit straighter.

The 8-station version has 8 pairs of rolls, of which six have reducing function and two have calibrating function. All machines are now equipped with 2-HP motors as standard, ensuring adequate roll pressure even for larger tube diameters.

The 12-station version has 12 pairs of rolls, of which ten have reducing function and two have calibrating function. All machines are now equipped with 2-HP motors as standard, ensuring adequate roll pressure even for larger tube diameters. The advantages of the 12-station rolling mill compared to the 8-station version are:

In the rolling mill with a fixed roll rotational speed, each pair of rolls is motorized via a fixed-speed geared motor.

In the rolling mill with a variable roll rotational speed, there is the possibility to program the rotation speed for each pair of rolls through frequency inverters, depending on the elongation of the elements. This solution allows to set the machine for different tube materials. Five sets of program scales of roll speed are available. Each pair of rolls will have a speed corresponding to the elongation of the tube, depending on the tube material. Having control of the speed of each roll station, it is possible to match as closely as possible the elongation occurring. This means that there is less friction between the rolls and tube, and therefore less heat generated by friction. As a result, the rolls last longer and the elements exit straighter.

The 8-station version has 8 pairs of rolls, of which six have reducing function and two have calibrating function. All machines are now equipped with 2-HP motors as standard, ensuring adequate roll pressure even for larger tube diameters.

The 12-station version has 12 pairs of rolls, of which ten have reducing function and two have calibrating function. All machines are now equipped with 2-HP motors as standard, ensuring adequate roll pressure even for larger tube diameters. The advantages of the 12-station rolling mill compared to the 8-station version are:

An innovation is transforming how heating elements are measured. Our new measurement unit, integrated at the rolling mill’s output, rapidly analyzes length, providing immediate feedback on conformity with customizable range settings to meet your specific requirements.

Material of tube to be reduced | Stainless steel, copper |

Min. length of heating element | mm 250 |

Tolerance on heating element diameter after diameter reduction (new rolls) | mm ±0,05 |

Rolling axis height from base | mm 915 |

Power supply | V to be defined |

Dimension 8 station roll reducing mill - weight 1200 Kg | mm 350 x 1700 x H 1130 |

Dimension 12 station roll reducing mill weight 1800 kg | mm 1670 x 1700 x H 1130 |

Reduction in the area of the section | up to 30% (8 station roll reducing mill) |

Reduction in the area of the section | up to 35% (12 station roll reducing mill) |

Discover the other products in our range